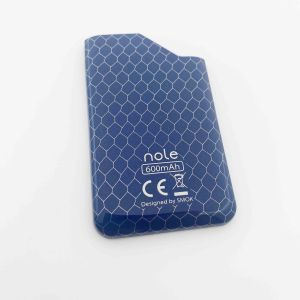

IMD Injection Moulding Facial Massage Machine Shell With Curved

Appearance And Transparent Lighting

The characteristics of IMD process curved products include:

By forming in one go, multiple effects such as matte, steam

plating, and metal wire drawing can be achieved simultaneously.

Strong deformation resistance, scratch and wear resistance, and

long service life.

It can achieve effects such as "texture", "color stereoscopic", and

"multi color".

The production process is environmentally friendly.

In addition, IMD process curved products also have the following

advantages:

Strong deformation resistance: able to withstand a certain degree

of deformation and not prone to cracking, bending, and other

phenomena.

Scratch and wear resistance: High surface hardness, good wear

resistance, and less prone to wear and loss of luster.

Long service life: After reasonable design and processing, the

product's service life is guaranteed.

Environmentally friendly materials: Made using environmentally

friendly materials, which are environmentally friendly.

In summary, IMD process curved products have unique design, strong

deformation resistance, scratch resistance, wear resistance, and

other advantages. At the same time, the production process is

environmentally friendly, making it a recommended manufacturing

process for curved products.

At the same time, it also possesses all the characteristics of IMD

products.

IMD Parts process introduction:

In Mold Decoration(IMD): use PET film coated on the surface as the

carrier to print ink pattern layer, adhesive and ink curing on the

printing surface. Then it is heated and baked for hot pressing

forming and trimming. Put the shaped PET film into the injection

mold cavity through manual or mechanical hand to fill the plastic,

and melt the adhesive to bond the PET film with the ink pattern

layer to form a whole with the plastic under high temperature.

Expansion area:

In addition to PET materials, it can also be cloth, PU leather,

wood chips, bamboo chips and other sheet materials

Why choose us

We are the first professional IMD PARTS manufacturer in

China,Founded in 2009, the company's industrial park covers an area

of more than 30000 square meters, has a high-precision dust-free

workshop, and has nearly 100 excellent management personnel, 35

engineering and technical personnel, 50 quality personnel, a total

of nearly 500 employees, more than 500 injection molding equipment,

and a monthly production capacity of nearly 15 million pieces; From

engineering research and development to mold production, diaphragm

printing, diaphragm molding, diaphragm injection molding,

inspection and packaging, there is a complete process production

process.

Full-process dust-free workshop operation

Full-process dust-free workshop operation

Our company has won the honors of high-growth enterprise, industry

benchmark enterprise, contract-abiding and creditworthy enterprise,

high-tech enterprise, etc

HXS has become a long-term partner of more than ten top 100

enterprises in the world