Anti-dirty Industrial Ceramic Parts Oil Drilling Machines

Properties:

a) Wear resistant

b) Corrosion resistant

c) Heat resistant .

d) Stable dimensions

e) Lightweight ,

f) Long performance life

Industrial Ceramic Intriduction

Aluminium Oxide, Al2O3 is the most widely applied and cost

effective technical ceramic material. It offers a combination of

superior mechanical strength and electrical properties, wear

resistance and corrosion resistance. The maximum working

temperature is up to 1700 °C with relatively high thermal

conductivity. It is also an electrically insulating material with a

high electrical resistivity. The good corrosion resistance makes it

insoluble in water and slightly soluble in strong acid and alkaline

solution.

Product Description

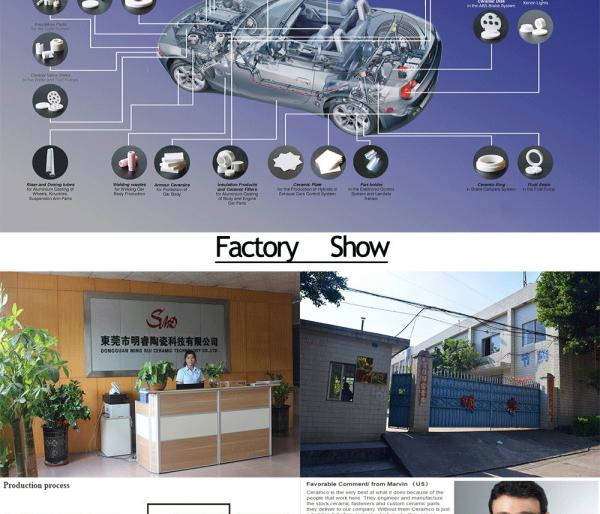

Precision Ceramics has years of experience designing and developing

technical ceramic solutions for a wide variety of applications and

industries. Anti-dirty Industrial Ceramic Parts Oil Drilling

Machines. We offer this expertise to all of our customers to ensure

the best design and materials are chosen for their specific

application and needs. Anti-dirty Industrial Ceramic Parts Oil

Drilling Machines, Typically, our custom technical ceramic

components and parts we supply are used for one of three main

reasons:

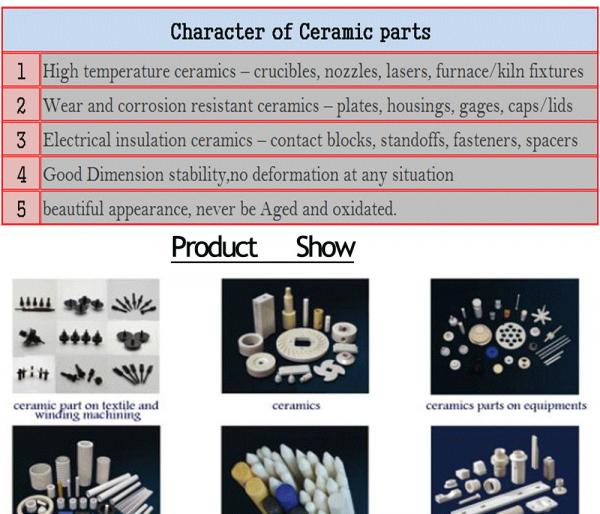

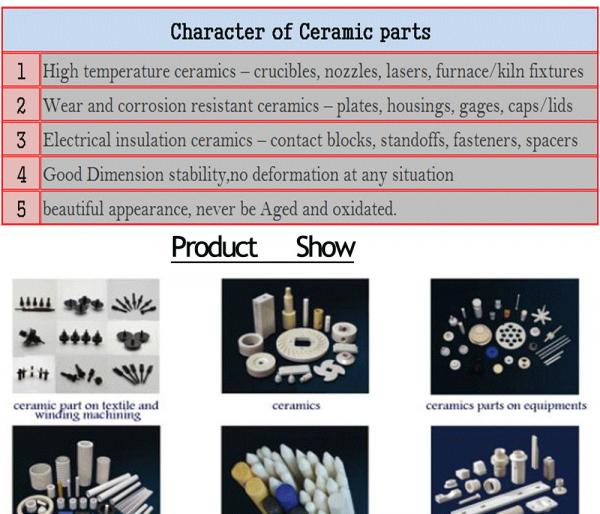

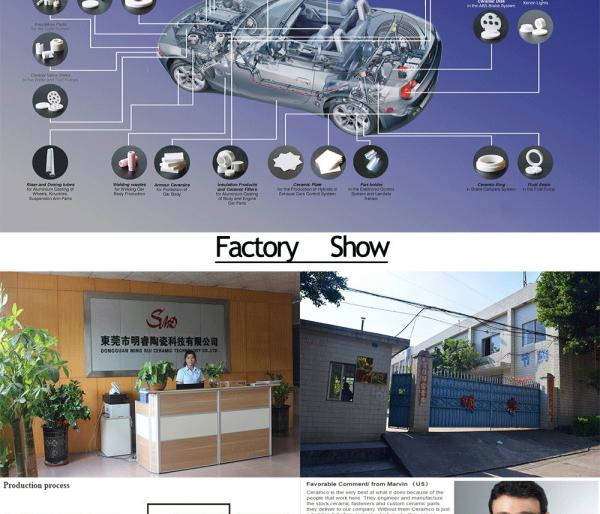

Anti-dirty Industrial Ceramic Parts Oil Drilling Machines

High temperature ceramics – crucibles, nozzles, lasers,

furnace/kiln fixtures

Anti-dirty Industrial Ceramic Parts Oil Drilling Machines

Wear and corrosion resistant ceramics – plates, housings, gages,

caps/lids

Anti-dirty Industrial Ceramic Parts Oil Drilling Machines

Electrical insulation ceramics – contact blocks, standoffs,

fasteners, spacers

Anti-dirty Industrial Ceramic Parts Oil Drilling Machines

Precision Ceramics is one of the world’s premiere technical ceramic

suppliers – contact us to see what technical ceramics we can create

for you.

Anti-dirty Industrial Ceramic Parts Oil Drilling Machines

| General Characteristics of Materials: |

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium |

High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Anti-dirty Industrial Ceramic Parts Oil Drilling Machines |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Anti-dirty Industrial Ceramic Parts Oil Drilling Machines |

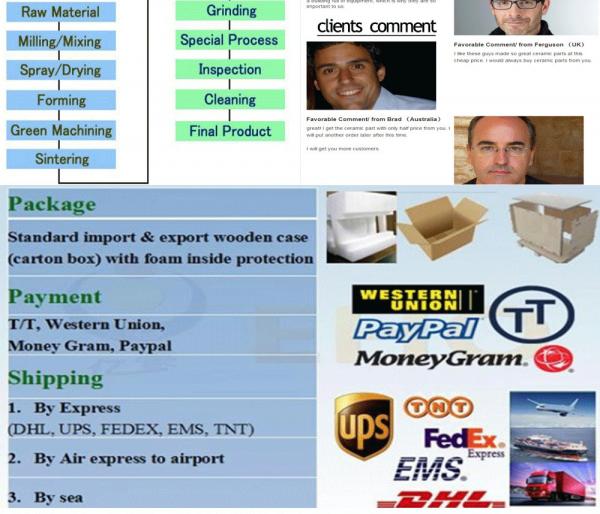

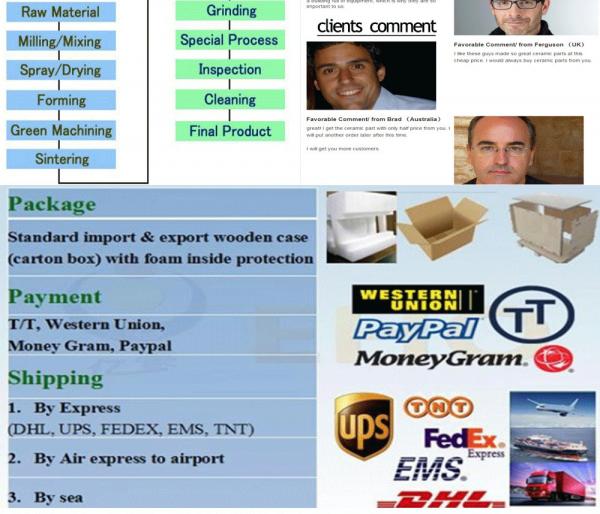

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.