Customized Machining Alumina Ceramic Tube / Advanced Technical

Ceramics Tube Parts

Zirconia Ceramic

Zirconia is one of the most studied ceramic materials. Zirconium

dioxide (in its most naturally occurring form) is the mineral

baddeleyite. Zirconia begins its life following a thermal treatment

process (calcining) of the zirconium dioxide. This zirconia is

further processed into different forms, including powder. Ceramic’s

zirconia formulations utilize a “ready to press” type of zirconia

powder for its near-net shaping manufacturing process.

Tough… Tougher

With a melting point of 2715°C and a boiling point of 4300°C, pure

zirconia is extremely tough. However, when heated, phase changes in

its physical characteristics reveal a weakness. In its tetragonal

phase the expansion of a pure zirconia part results in internal

stresses, leading to cracks. This inherent weakness is corrected

with the addition of a stabilizer, such as yittria(Yttrium oxide, Y2O3), producing YTZP, a yittria partially stabilized zirconia.

A part made of YTZP zirconia remains stable as is moves from its

monoclinic (room temperature) phase to its tetragonal (heated)

phase and back again, resulting in lessened expansion, and minimal

crack propagation. These changes are referred to as Transformation

Toughening.

Ceramic manufactures custom ceramic parts of YTZP zirconia for

various markets with equally different environments. However, the

common threads found making YTZP zirconia the material of choice

often includes:

1. Resistance to high abrasion

2. Chemical stability

3. Coefficient of thermal expansion similar to steel

Industrial Ceramic Intriduction

Aluminium Oxide, Al2O3 is the most widely applied and cost

effective technical ceramic material. It offers a combination of

superior mechanical strength and electrical properties, wear

resistance and corrosion resistance. The maximum working

temperature is up to 1700 °C with relatively high thermal

conductivity. It is also an electrically insulating material with a

high electrical resistivity. The good corrosion resistance makes it

insoluble in water and slightly soluble in strong acid and alkaline

solution.

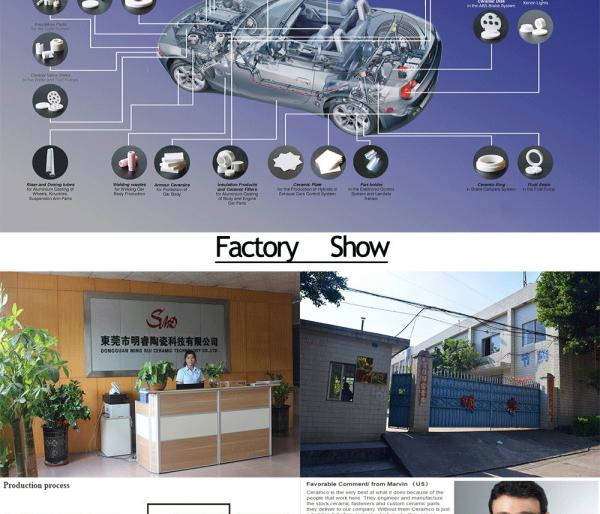

Product Description

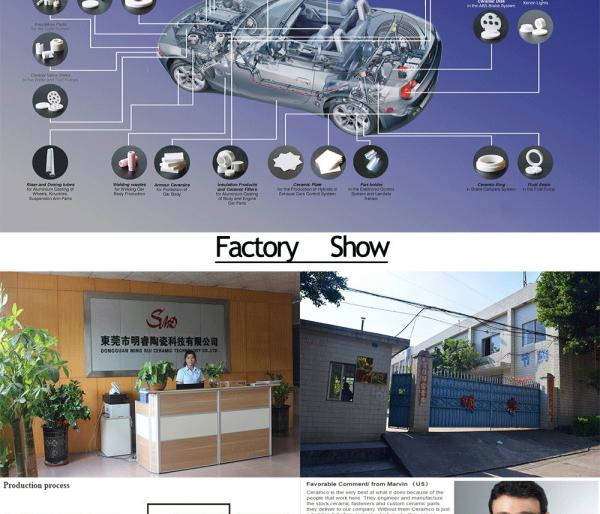

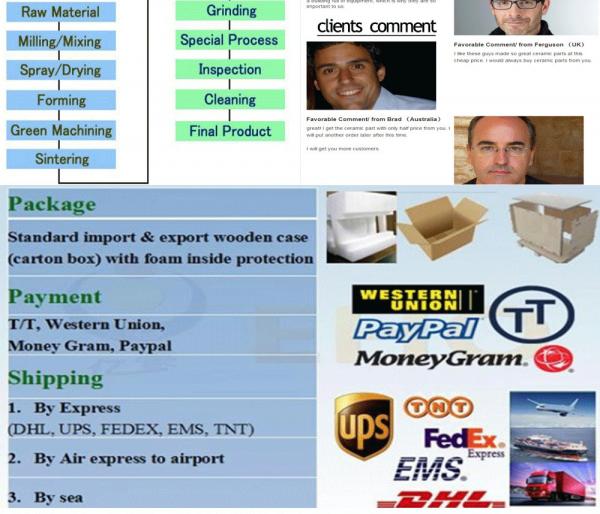

Precision Ceramics has years of experience designing and developing

technical ceramic solutions for a wide variety of applications and

industries. Low Coefficient Of Friction Alumina Ceramic Parts

Welding Machines. We offer this expertise to all of our customers

to ensure the best design and materials are chosen for their

specific application and needs. Low Coefficient Of Friction Alumina

Ceramic Parts Welding Machines, Typically, our custom technical

ceramic components and parts we supply are used for one of three

main reasons:

Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines

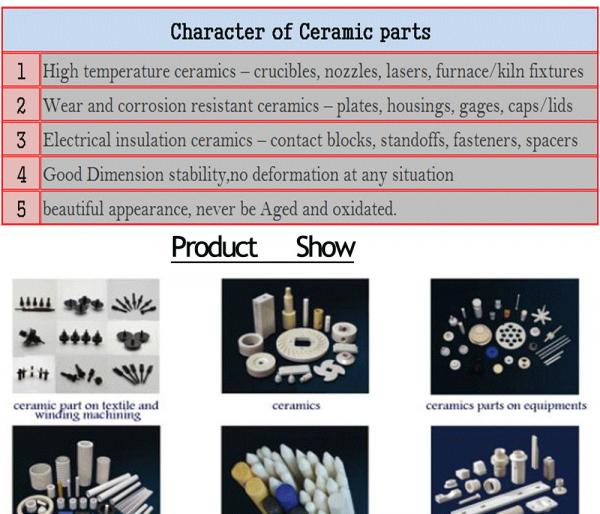

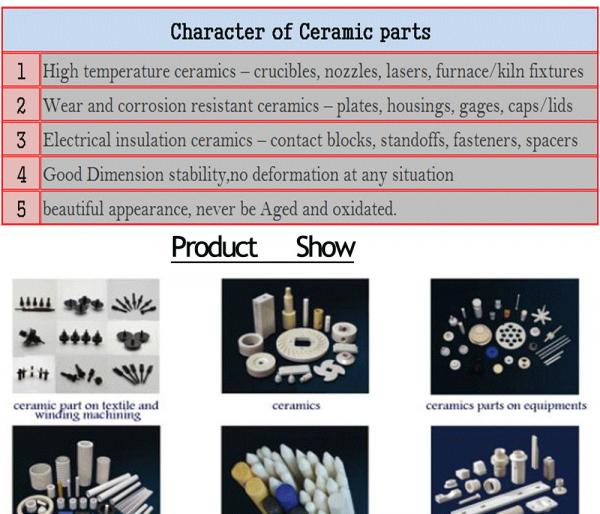

High temperature ceramics – crucibles, nozzles, lasers,

furnace/kiln fixtures

Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines

Wear and corrosion resistant ceramics – plates, housings, gages,

caps/lids

Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines

Electrical insulation ceramics – contact blocks, standoffs,

fasteners, spacers

Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines

Precision Ceramics is one of the world’s premiere technical ceramic

suppliers – contact us to see what technical ceramics we can create

for you.

Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines

| General Characteristics of Materials: |

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium |

High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Low Coefficient Of Friction Alumina Ceramic Parts Welding Machines |