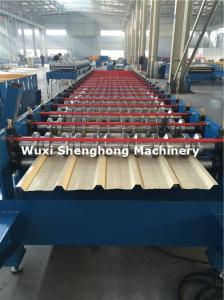

Cable tray Roll Forming Machine

Quick Details

- Condition: New

- Type: Cable tray roll forming machine

- Tile Type: Steel

- Use: Step support

- Production Capacity: 10 m / min

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: Wuxi Shenghong

- Power(W): 15 KW

- Voltage: 380v, 3phase, 50Hz or at buyer`s requirement

- Dimension(L*W*H): Length: 8000 * Width1000 * Height:1400mm

- Weight: around 8000 kgs

- Certification: CE, ISO9001:2008

- Warranty: 1year

- Punching type: optional

- Roller stands: aound 16stands

- Passive uncoiler: 3T

- Controller: PLC

- Roller driven type: Chain transmission

- Thickness: 1.5-3.0mm

- Main motor power: 15kw

- Hydraulic station power: 5.5kw

Components

This line includes 3tons un-power uncoiler, sheet guiding

equipment, leveling system, roll forming system, cutting equipment,

hydraulic station and electric controlling system

Technical Parameters

Material Spec Galvanized steel sheet at stress 350Mpa (50ksi);

Thickness: 0.7~2.5mm,

Main motor power 15KW

Hydraulic station power 5.5KW

Cutting Tolerance ≤±1.0mm (length≤ 3000mm)

≤±2.0mm ( 3000mm < length ≤ 5000mm)

≤±3.0mm ( 5000mm < length ≤ 10000mm)

≤±5.0mm ( 10000mm < length)

Roll Forming Speed 10m/min

Main roller round 16 stands

Main body dimension round 8000*1000*1400mm

Control system PLC

Material of Main Equipment

Roller Material High grade mold steel Cr12 with quenched treatment,which can improve the integrated mechanic

feature of the rollers

Active Shaft Material High grade No.45 carbon wrought steel,which can improve the

integrated mechanic feature of the shaft

Electric Elements PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

Cutter blade Cr12 mould steel with quenched treatment

Component and Function

Coil Feeding Equipment Consists of one uncoiler with capacity of 3000kgs and its base.

The mandrel can expand or shrink. With separate button to make the

mandrel roll.

Guiding Equipment Adopting guiding bar and sliding block to control the width and

position of the steel sheet. The coil is guided in the correct

position and passed to the roll forming equipment.

Roll forming system The main frame of machine is welded separately and the outside

wall is connected by screw after being roto-blasted on the surface.

The rollers with quenched treatment after being machined by the

exact machining tool.

Hydraulic Station Supplies the initial power to the cuter through a closed oil tank.

It is off without cutting, which can save the power.

PLC Control Panel Main parts imported from Mitsubishi. The operation is easy and

steady and can be choose operation by manual or automatically.

Working Flow

Decoiling the sheet Sheet guiding leveling the sheet Roll forming

Cutting the panel

Introduction of Cable Tray Roll Forming Machine

1. Cable tray Roll Forming Machinebiggest and most competitive

machinery manufacturer in China, Cable tray Machine is widely used

as the supporter of cable in large-scale and mid-scale

construction, such as factories,warehouses, garages, exhibition

centers, cinemas, theatres and gardens. The products of cable tray

roll forming machine have excellent anti-bending property and are

easy to install.

2.The machine is full-automatically controlled by PLC, the whole

hydraulic transmission, drive hydraulic oil jar carry out and shear

through center pump station towards the hole, hydraulic pressure

Motortransmit power as main transmission. it' s reliable to operate

steadily by hydraulic pressure, shear towards hole precision

geometry form rule of the notch. Its hydraulic pressure

transmission,to set correct and fit.

3.Cable tray Forming Machine can produce many types of cable

tray.The whole line mainly consists of uncoiler and its base, coil

sheet flattening equipment, punching equipment , pre-cutting

equipment,C-shape forming system, hydraulic station, and PLC

controlling system.

Packaging & Delivery

Packaging Details: | 1. Export standard package for container

2. Host nude, wheels with oil and gas bubble cushion packaging.

3. PLC controller with bubble cushion packaging

4. Spare parts in wooden cases. |

|---|

Delivery Detail: | about 40 days |

|---|

Machinery Shows