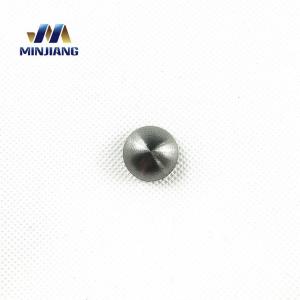

Cemented/Tungsten Carbide Valves Spare Parts For Oil And Gas

Industry

Description

Tungsten carbide parts are a type of industrial component used in a

wide range of applications. Made from a combination of tungsten and

carbon, these parts are incredibly strong and durable. They are

often used in the manufacture of cutting tools, wear parts,

drilling tools, and even aerospace components. Tungsten carbide

parts are also resistant to high temperatures, making them ideal

for applications where heat is an issue. Their hardness and

strength also make them useful components in a variety of

industries. Their low cost makes them a great choice for

manufacturing and engineering projects. Tungsten carbide parts are

an excellent choice for those looking for a long-lasting, reliable,

and cost-effective solution.

Specification

| Name | Tungsten Carbide Parts |

| Applications | Oil and Gas Industry |

| Dimensions | Customized |

| Lead Time | 35 days |

| Material | YG6/YG8/YG11/YG13 |

| Certificates | ISO9001:2008 |

| Samples | Negotiable |

| Package | Carton Box |

Competitive Pros

High-Quality Control: This refers to the quality control process that goes into making

the parts. We inspect each part at every stage of production to

ensure that the highest quality product is being delivered to our

customers.

Abrasion Resistance: This refers to the ability of the parts to resist wear and tear

during use. The parts need to be able to withstand the tough

materials they are cutting through and remain strong.

Heat Treatment: This refers to the heat treatment process that is used to improve

the strength and hardness of the parts. By using heat treatment, we

can increase the strength and durability of the parts.

Surface Treatment: This refers to the process of treating the surface of the parts to

increase the lifespan. This includes polishing and coating the

parts to protect it against wear and tear.

Source Supplier

Shopping directly from the factory source offers numerous benefits for customers. Cost savings is one of the most attractive benefits, as it eliminates the need for a middleman. Additionally, customers can ensure the highest quality of products as they come from the source of production. Timely delivery is also guaranteed, and orders can be customized to meet the needs of the customer. Lastly, customers are able to form a relationship with the factory, providing them with better customer service.

Competitive Advantages

- Precise Casting: This refers to the specialized process we used to

make the nozzles. It involves exact measurements and exact

temperatures to ensure that our nozzles are made to exact

specifications.

- Super Hardness: This refers to the hardness of the material that

our nozzles are made out of. Carbide nozzles require a strong,

durable material in order to cut through tough materials and last

for a long time.

- Enduring Resistance: This refers to our nozzle's ability to remain

wear-resistant for a long period of time.

- Stabilization Durable: This refers to the stability and durability

of our nozzles. The blades need to be able to withstand tough

conditions and remain stable over time without wearing down

quickly.

FAQ

1. Q: What is the best way to contact you?

A: You can contact us by email, telephone, or online chat.

2. Q: Do you offer customized products?

A: Yes, we offer customized products to fit the client's demands.

3. Q: What is the benefit of using Tungsten Carbide Parts?

A: Using Tungsten Carbide Parts provides a number of advantages. It

is renowned for its strong and durable properties, making it ideal

for a variety of applications. It also offers a long service life

and excellent performance even in harsh working conditions.

Furthermore, it is highly resistant to corrosion, providing

superior protection in wet or humid environments.