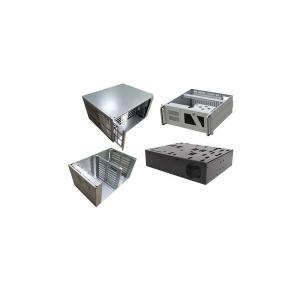

Certified Factory Custom Sheet Metal Enclosures Sheet Metal Sheet

Metal Case

Description of Custom Sheet Metal Enclosures

Stamping (also known as pressing) is the process of placing flat

sheet metal in either blank or coil form into a stamping press

where a tool and die surface forms the metal into a net shape.

Stamping includes a variety of sheet-metal forming manufacturing

processes, such as punching using a machine press or stamping

press, blanking, embossing, bending, flanging, and coining. This

could be a single stage operation where every stroke of the press

produces the desired form on the sheet metal part, or could occur

through a series of stages. The process is usually carried out on

sheet metal, but can also be used on other materials, such as

polystyrene. Progressive dies are commonly fed from a coil of

steel, coil reel for unwinding of coil to a straightener to level

the coil and then into a feeder which advances the material into

the press and die at a predetermined feed length. Depending on part

complexity, the number of stations in the die can be determined.

Specifications of Custom Sheet Metal Enclosures

| Advantage | One-Stop Solution for Mechanical Customers

Rich experience in Small Volume & Large variety

Rich experience in Large Volume

20 Years field experience, and 80+ engineers |

| Processing Method | CNC machining. Turning. Milling, Stamping, Sheet metal. Screw

manufacturing, Assembly |

| Materials Available | Stainless steel Carbon steel, Brass, Bronze. Iron, Alumunum alloy,

Nylon, SPCC, SECC, etc. |

| Materials Standard | GB. ASTM, EN, DIN, JIS, BS, ANSI. SAE |

| Processing Capacity | Outer diameter: 0.5mm-500mm Length: 1.0mm-2000mm |

| Tolerance | ± 0.002mm |

| Surface Treatment | Anodizing, Sandblast, Electroplating. Powder coating.

Liquid Painting, PVD, Electrolytic polishing, ect. |

| Equipment | Over 70 sets automatic lathes, over 30 sets CNC lathes,

over 10 sets CNC machining center,

over 200 sets secondary processing machines. |

| RFQ | Customer Inquiry → Engineering Communication → Cost Analysis →Sales

Analysis →Quote to Customer

» 1-3 Work Days Only

» Submit RFQ with complete commercial terms |

| Sample Making | Sample Order → Engineering Review → Sample Plan to Customer →

Sample Status Tracking → Submit Samples with Doc.

» Tooling L/T: 2-4 wks. Sample L/T: 2 wks

» Continuous Sample Status Tracking

» Complete Documents for sample approval |

| Order Management | CRM System → Open Order Confirm → Logistic Arrangement.

» Production L/T: 2-4 wks

» Weekly Open Order Confirm

» Preferred 3PL Service to Customers |

| Quality Control | Certificates: RoHS, 1809001:2015, SGS.

IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit &

Training.

» Plant Audit and Qualified by world famous company

» Strict Quality Management Procedure with Traceability |

Features of Custom Sheet Metal Enclosures

1. Good corrosion resistance

2. High strength

3. Good finishing characteristics

4. Good bending performance

Applications of Custom Sheet Metal Enclosures

1. Aerospace

2. Automotive industries

3. Instruments

4. Office equipments

5. Home appliances

6. Medical equipments

7. Electrical & electronics

8. Communication equipments

Quality Control

1. Quality control :The defective products rate is 0.1%. Imported

material 100%.

2. Reasonable price , Precision made.Experience & Reasonable QC

that you can reply on.

3. Each part would be given 100% test and tryout before shipment.

4. Adequate supply capacity. Punctual delivery time.

FAQ

1. Are You Factory/Manufacturer Or Trading Company?

We are factory/manufacturer of CNC Machining Parts with over 10

years' experience.You can get competitive price SMT Mounting

Machine here of high quality.

2. Do You Offer OEM/ODM Service?

Yes, we have rich experience in offering OEM/ODM service. Design

service offered.

3. Can machines be used at outside?

With waterproof function, could be used at outsise.

4. What is your MOQ?

Any quantity is acceptable.