Shaanxi Rongbao Machinery Electronics Co., Ltd.(formerly known as: Xianrongbao Machinery Electronics Co., Ltd.)

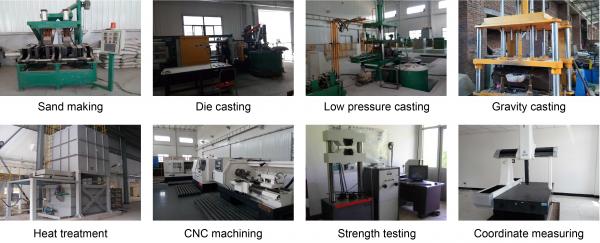

which located in the Fengjing Industrial Park is specialized in production of high-quality aluminum sand casting products, aluminum gravity die

casting products, low pressure and die casting products, CNC

processing products.

Our products

We supply stainless steel casting, aluminum casting, copper casting and precise machining.

Products are widely used in automobiles, machinery, hydraulic

parts, hardware, explosion box, motor parts, power tools, valves,

flanges, air conditioning joints, robots, sewing, medical

equipment, gear boxes, pipeline parts, snow machines, pump boxes,

impellers, etc..

Our Factory

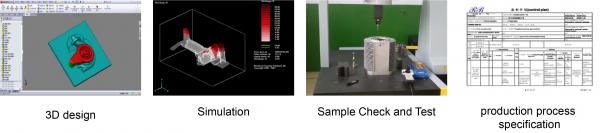

Our company currently covers an area of over 5,000m2 of production and manufacturing base, owns a high-quality

professional team, with first-class production equipment and

testing equipment to ensure high reliability of products. Two

patents for utility models have been obtained and certified by the ISO 9001:2015 quality management system.

Our Businesses

Our company has been engaged in the production, processing and

sales of casting products and CNC processing products for 14 years. Our customers come from a diverse industry field. 90 % of casting and machinery products are exported to the United States, Europe, Australia, Russia and other

countries.

Our Mission

Under the guidance of "innovation is infinite, honesty is eternal",

Shaanxi Rongbao will display the grand prospect with the spirit of "Struggle and forge ahead". All employees of

Shaanxi Rongbao warmly welcome people from all walks of life to

come to the guidance.

Welcome to inquire us prices and visit our company !