Overview:

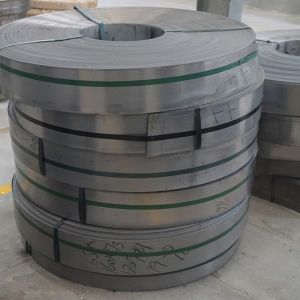

Low carbon steel strip, also known as soft steel, has a carbon

content ranging from 0.10% to 0.30%. The use involves metal hose

belts, flange packing belts, saw blade steel belts, blade steel

belts, spring washers, bicycle steel belts, stationery steel belts,

hair clips steel belts, electrical fasteners steel belts, armored

cables steel belts, heat dissipation fins steel belts, prestressed

corrugated pipes steel belts, clocks and watches steel belts, etc.

Low carbon steel is generally rolled into angle steel, channel

steel, I-beam, steel pipe, steel strip, and steel plate, and is

used to make various building components, containers, boxes,

furnaces, and agricultural machinery. High quality low-carbon steel

is rolled into thin sheets to produce deep drawn products such as

car cabins and engine hood; It is also rolled into bars and used to

make mechanical parts that do not require high strength. Low carbon

steel generally does not undergo heat treatment before use. Parts

with carbon content above 0.15% are carburized or cyanide treated,

and are used for shafts, bushings, sprockets, and other parts that

require high surface roughness and good wear resistance. Low carbon

steel is limited in use due to its low strength. Properly

increasing the manganese content in carbon steel and adding trace

alloying elements such as vanadium, titanium, and niobium can

greatly improve the strength of the steel. If the carbon content in

steel is reduced and a small amount of aluminum, boron, and carbide

forming elements are added, an ultra-low carbon bainite composition

can be obtained, which has high strength and maintains good

plasticity and toughness.