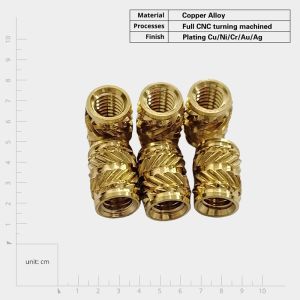

CNC Turning Service

Get quality custom turned parts for rapid prototyping and end-use

production. Lead times are as fast as 2 day.

Capabilities

Our CNC turning process produces custom prototypes and end-use

production parts in as fast as 1 day. We use a CNC lathe with live

tooling so features like axial and radial holes, flats, grooves,

and slots can be machined.

CNC turning is often used for:

- functional prototypes and end-use parts

- parts with cylindrical features

- parts with axial and radial holes, flats, grooves, and slots

Design Guidelines for CNC Turning

Our basic guidelines for CNC turning include important design

considerations to help improve part manufacturability, enhance

cosmetic appearance, and reduce overall production time.

| | US | Metric |

| Maximum Dimensions | Diameter | 3.95 in. | 100.33mm |

| Length | 9 in. | 228.6mm |

| Minimum Dimensions | Diameter | 0.16 in. | 4.07mm |

| Length | 0.05 in. | 1.27mm |

| Wall Thickness | 0.020 in. | 0.51mm |

| Angle | 30° | 30° |

| Tolerances | +/- 0.005 in. | +/- 0.13mm |

Additional Notes on CNC Turning Guidelines

- Small features may be allowed, but the diameter in any region

should not be less than 0.030 in. (0.76mm).

- Sharp conical points are allowed; angles should be greater than 30

degrees. Walls thinner than 0.020 in. (0.5mm) typically do not

survive the machining process.

Materials for CNC Turning

We stock a range of metal materials that are suitable for various

part applications and industries. Choose from aluminum, brass, low

carbon steel, stainless steel, steel alloy, and titanium for turned

parts.

- Aluminum

- Brass

- Low Carbon Steel

- Steel Alloy

- Stainless Steel

- Titanium

- Plastics

Finish

- Anodizing

- Chromating

- Plating Cu/Ni/Ag/Cr/Au

- E-coating

- Polishing