Jiangsu Huixuan New Energy Equipment Co., Ltd.

Company Profile

Jiangsu Huixuan New Energy

Equipment Co., Ltd. was established in June, 2016, is one of the

forging manufacturer especially for the forging export. We located

in Jiangsu Province of mid-east of China with good location for

abundant sea transportation and just 90km to Shanghai airport. We

have five professional plants: free-die forging, ring rolling,

rough machining, heat treatment and finish machining. Our annual

production capacity is 80,000 tons for various of free-die

forgings, ring rollings and formed forgings.

We have advanced supporting

facilities, such as each of 10000t&3500t free-die forging

hydraulic oil presses, each of 8T,5T,3T hammer,each of Ф9000mm and

Ф5000mm ring rolling machine, one set of in-and-out material

machine, 3 forging operators with the capacity of 150tons, 50tons

and 20tons, various lifting vehicles, natural gas furnaces, chamber

furnaces, sawing machines, drilling machines, heavy

horizontal&vertical lathers, CNC machines, plane milling and

boring machines, deep holeboring machines etc., totally more than

200 sets. All of these machines ensure to provide the coordinated

process service from rough to finish machining. our customers are

around the world,thanks to good company location we are able to

provide fast ocean,air and railway transportation, achieved any

location,any time,any problems quick response service.

Our principle is Quality is First. Each

quality key ponits from raw material to finish machining , packing

and shipment will have the inspector to control the production

quality management and ensure the 98% products percent of pass. And

our execute standard can meet the international general standard,

such as JB/GB/EN/DIN/JIS/ASME/ASTM/ISO. We are the training base of

China Forging Association and after we set up our Jiangsu Huixuan

Technology Research Center, spectrometer lab, mechanical properties

test lab, metallographic lab and NDT lab. There are direct reading

spectrometer, carbon and sulfur analyzer, 300KN electronic testing

machine, 600KN hydraulic testing machine, impact testing machine,

metalloscope, oxygen nitrogen and hydrogen analyzer and so on, and

can implement the NDT test such as UT, MT, PT and so on to ensure

the product quality.

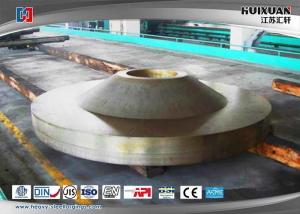

We can provide the forging with weight from 0.5t

to 150t, and our main products are megawatt wind power main shafts,

hydropower and thermal power rotors, power station auxiliary

equipment spare parts, ship forgings for power of bent exle or

propulsion of shafting, kinds of mining machinery forgings, step

shafts, large gear rings, offshore oil and gas engineer forgings,

oil forgings, special pressure vessel forgings and some others that

can be used in kinds of heavy industry equipments field.

We are qualified by the classifications such as

ABS, CCS, BV, LR, DNV, GL, KR, NK, RINA and got the approval

certifications. Beside that, we also have PED pressure equipment

production license of TUV and "special equipment manufacturing

license". We also gain some honors such as " Jiangsu Province

High-tech and New Enterprise"," Jiangsu Province Private Technology

Enterprise", and" China Top 10 Wind Power Main Shafts Manufacturing

Enterprise "," National Quality Management Best Award of Excellence

"," Jiangsu Province Excellent Private Enterprise "," Jiangsu High

Quality Products ", " Jiangsu Fareast International AAA Credit

Rating Enterprise".

We invite the domestic and foreign

merchants to cooperate sincerely and seek the common development,

to create the brilliant together! !