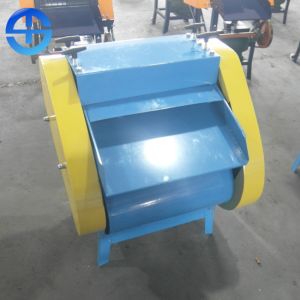

Features of scrap metal recycling machine

1. Easy operation, small land occupation.

2. High performance with 100% separateing rate.

3. In terms of safety, set up the light eye control at the inlet of materials, and when working, set up the position by hand, and the machine stops running.

4. It is time-saving, labor-saving, investment-saving, easy to operate and easy to maintain.

Working process of scrap metal recycling machine

(1). Turn the Reversing Switch and check the rotating direction.

(2). Inject oil into the two oil holes in the left and right side of the machine to lubricate transmission gears (normally once per 4 working hours).

(3). Push different radiators into different Material Inlets according to their specs (19mm, 21mm, 25mm); the left side of radiators must touch the left side of Material Inlets. Or the right side of radiators must touch the right side of Material Inlets (the first copper pipe in the Lower Layer shall be nearer to the Guiding Ruler). When radiators are pushed into Material Inlets, Feeding Gears will gnaw at radiators and take them into the machine.

(4). After radiators are taken into the machine, copper pipes and aluminum are separated and come out of the machine automatically.

(5). According to the layers of radiators and their height, adjust each pair of Adjusting Wheels on the machine (after adjusting, tighten screws below).

Attention of scrap metal recycling machine

1. In radiator separating, if radiators move towards left direction or right direction, check if the two Adjusting Wheels of each pair are on the same level.

2. When abnormal noise appears in working, check the working conditions of transmission gears, bearings and Speed Reducer as well as motors.

3. When radiators can not be cut from top to bottom, check if Triangle Belts are loose which causes slipping; or check if the blades become blunt.

4. After working for a period, Speed Reducer lubricant shall be replaced; check if screws become loose or not; check if blades and Feeding Gears become loose or not.

Specification of scrap metal recycling machine

| Model | TMS-017 |

| Machine size | 1800*800*1200mm |

| Production | 2000-3000kg/day |

| Motor power | 3kw+4kw |

| Weight | 600kg |

| Power supply | 380V/50HZ, 3 Phase. Or customized as customers' requiement |