Trumony Aluminum Limited

Trumony Group was established in 2007. With more than 10 years

development , now Trumony is national high-tech enterprise .

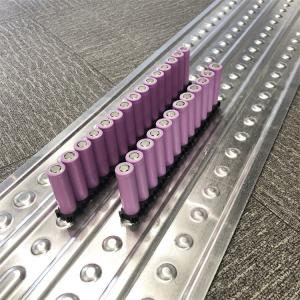

specialized in production of battery thermal management components

, thermal interface material , aluminum brazing material and

extruded profile.

Trumony group headquarters is located at Suzhou city , including 4

companies Trumony Aluminum Limited (aluminum lightweight products

manufacturer ),Trumony Energy Limited (battery thermal management

parts and surface treatment manufacturing center),Trumony

Technology Limited ( thermal interface material manufacturer ) and

Trumony Brazing Limited ( components manufacturing center).

We,Trumony is committed to providing clean aluminum material

solution to the market."Through the discovery and creation, to

bring value to customers" is the company philosophy. "Diligence,

pragmatic, keep exploring and mutual assistance" is the company

culture.