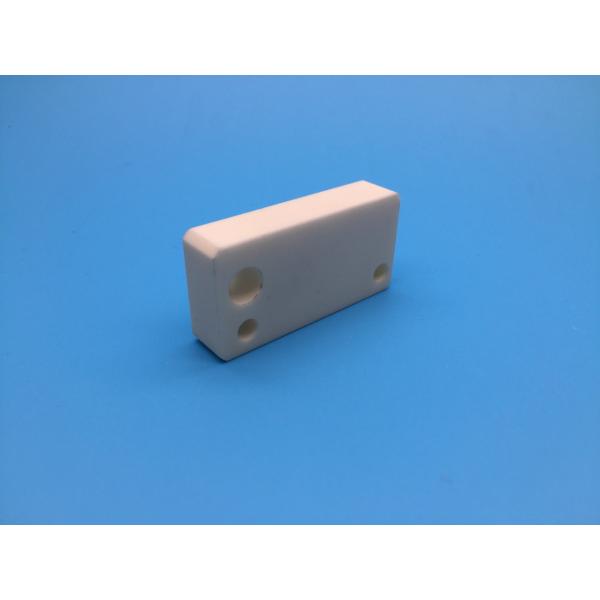

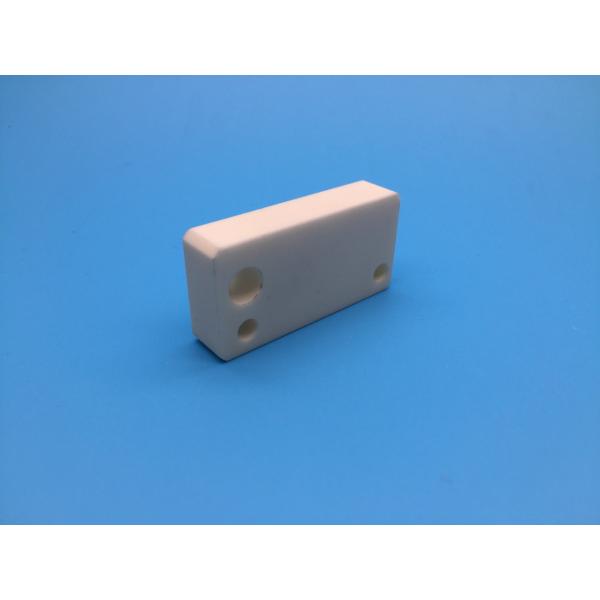

Bar Shape Alumina Parts High Hardness Bend Strength Ceramic Bar

Plate Components

Alumina Ceramic is the most cost effective and widely used material

in the family of engineering ceramics. The raw materials from which

this high performance technical grade ceramic is made are readily

available and reasonably priced, resulting in good value for the

cost in fabricated alumina shapes. With an excellent combination of

properties and an attractive price, it is no surprise that fine

grain technical grade alumina has a very wide range of

applications.

Application:

1, Ceramic complex pipeline of glass fiber reinforced plastics

2, Alumina ceramic liner for cement cyclone

3, Metal complex pipeline and elbow

4, Wear-resistant liner for down spouting

5, Wear-resistant liner for pipeline

6, Preheater bracket

Properties Sheet:

| Properties | Units | 95 Alumina | 99 Alumina | Zirconia |

| Density | ɡ / cm3 | 3.65 | 3.92 | 5.95 - 6.0 |

| Water Absorption | % | 0 | 0 | 0 |

| Coefficient of Thermal Expansion | 10-6 / K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young’s Mod | Gpa | 280 | 340 | 210 |

| Poisson’s Ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness | Mpa | 1400 | 1650 | 1300 - 1365 |

| Flexural Strength @ Room Temperature | Mpa | 280 | 310 | 950 |

| Flexural Strength @ 700℃ | Mpa | 220 | 230 | 210 |

| Compressive Strength@Room Temperature | Mpa | 2000 | 2200 | 2000 |

| Fracture Toughness | Mpa * m½ | 3.8 | 4.2 | 10 |

| Heat Conductivity @ Room Temperature | W / m * k | 18 - 25 | 26 - 30 | 2.0 - 2.2 |

| Electrical Resistivity @ Room Temperature | Ω*mm2 / m | >1015 | >1016 | >1015 |

| Max Application Temperature | ℃ | 1500 | 1750 | 1050 |

| Resistance to Acid Alkaline | / | High | High | High |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV / mm | 16 | 22 | / |

| Thermal Shock Resistance | Δ T ( ℃ ) | 220 | 180 - 200 | 282 - 350 |

| Tensile Strength @ 25℃ | Mpa | 200 | 248 | 252 |

Detailed Images

View More Products

Packaging and Shipping

Ceramic al2o3 hydraulic plug valve will be packed in a bubble bag

individually, then separated by a foam, finally put in standard

export carton packing, or OEM packing.

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or Sea transportation.

Company information

Who Are We?

Mingrui has professional OEM experience in manufacturing industrial ceramic parts for so many

years. We can make the products according to your drawings, custom the size,

thickness and other parameters.

.

What Do We Do?

We have very advanced technologies in the production of zirconia and alumina ceramic nozzle, rod, ring, tube, shaft, plate,

sleeve, valve, plunger, bearing, and semiconductive ceramics etc.. They are applicable to Electrical, Appliance, Mining, Oil & Gas,

Energy & Power, Food & Medical, Agriculture, Aerospace,

even other High-end fields.

.

Our products with some certificates, such as , CE, TUV, etc..

Factory Show

Production Process Show

One-stop production, from the raw material ( powder ) to final

products, control the quality strickly of every production link.