Ceramic Al2O3 Re-Entrant Bushings High Temperature Ceramic Bushings

And Insulation Sleeve

Us supply many quantity standard ceramic bushings.The ceramic

bushes adopt silicon nitride or zirconia ceramic material. It is a

high temperature ceramic bushings and insulation sleeve.Our bushes

or sleeve are used on M4,M5,M6,M8,M10,M12 welding bolts.Accept

customized bushings according to your drawing or specification.With

high quality,welcome your enquiry.

| ID (mm) | OD (mm) | LENGTH (mm) | F DIA (mm) | G (mm) |

| 0.35 | 4 | 6 | 7 | 2 |

| 0.4 | 4 | 6 | 7 | 2 |

| 0.8 | 4 | 6 | 7 | 2 |

| 1.75 | 4 | 6 | 7 | 2 |

| 1.95 | 5 | 9 | 8 | 2 |

| 2.55 | 5 | 6 | 8 | 2 |

| 3.2 | 6 | 8 | 9 | 2.5 |

| 4.5 | 8 | 12 | 11 | 2.5 |

| 5.9 | 10 | 20 | 13 | 3 |

| 6.9 | 12 | 10 | 15 | 3 |

| 8.4 | 15 | 12 | 18 | 3 |

| 10.8 | 18 | 12 | 22 | 4 |

| 14.5 | 22 | 28 | 26 | 4 |

| 17.5 | 26 | 36 | 30 | 4 |

| 22 | 30 | 45 | 34 | 5 |

| 26 | 35 | 20 | 39 | 5 |

High Hardness

Low Coefficient of Thermal Expansion

Excellent Electrical Insulator

Mechanically Stable at High Temperature

Good Thermal Shock Resistance

High density, non-porous and vacuum tight

Resists Abrasive Wear and Chemical Attack

Properties Sheet:

| Properties | Units | 95 Alumina | Alumina AL2O3 | ZrO2 | Silicone Carbide | Silicone Nitride |

| Density | g/cm3 | 3.65 | 3.95 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | | 0 | 0 | 0 | 0 | 0 |

| Coefficientof thermal expansion | 10-16/k | 7.9 | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280 | 280-340 | 210 | 440 | 300 |

| poission`s ratio | / | 0.21 | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1400 | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength(room temperature) | MPa | 280 | 310 | 950 | 390 | 720 |

| Flexural strength(700℃) | MPa | 220 | 230 | 210 | 380 | 450 |

| compressive strength(room temperature) | MPa | 2000 | 2200 | 2000 | 1800 | 2300 |

| Fracture toughness | MPa*m1/2 | 3.8 | 4.2 | 10 | 3.9 | 6.2 |

| Heat conductivity(room temperature) | W/m*k | 18-25 | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity(room temperature) | Ω*mm2/m | >1015 | >1016 | >1015 | >103 | >1013 |

| Max use temperature | ℃ | 1500 | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high | high |

| Dielectric constant | / | 9 | 9.6 | 29 | 9.66-10.03 | / |

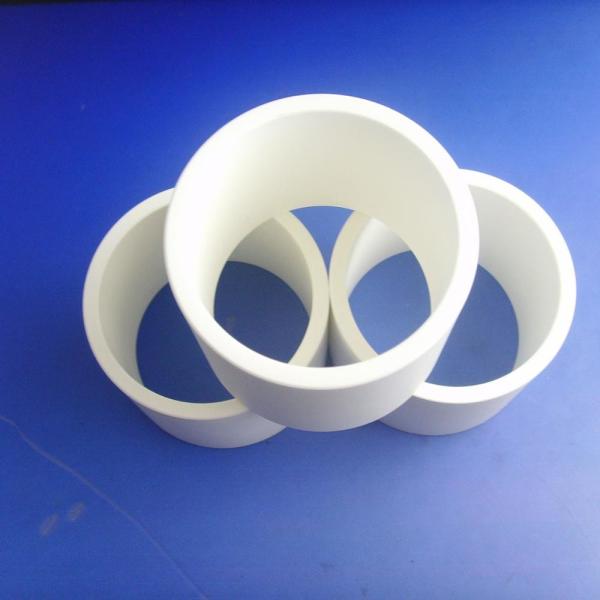

Detailed Images

Company Introduction:

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts, ceramic thread tube . Our main products include ceramic rod , ceramic tube, ceramic

plunger, ceramic valve, ceramic plate, ceramic shaft and bearing ,

ceramic nozzle etc , which are mainly used in industrial fields of

Machinery, Petrochemical oil and gas, Valves, Automotive, Food

Processing, Fluid Handling, Process Control, Thermal Processing,

Aerospace, Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great

successes in particular requirements

which is based on cooperating with Tsinghua University and getting

rich experience by our professional technical engineer teams . Our

factory have an unique technical called mirror polishing which

improve

our products more smooth , bright than other competitors.

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.