Small linear shaking table is very practical in chemical, food,

medicine and other industries. It has high screening accuracy,

large processing capacity, simple structure, low energy

consumption, low noise, long service life, good sealing, little

dust spillage and convenient maintenance.Often cooperate with other

mechanical equipment, such as conveyor, hoist, crusher, etc., to

complete the automatic operation of the whole assembly line. The

linear powder screening machine uses the vibration motor as the

vibration source, so that the material is thrown up on the screen

and moves forward in a straight line. The material evenly enters

the feed inlet of the screening machine from the feeder, and

generates several specifications of the upper and lower screen

materials through the multi-layer screen, which are discharged from

their respective outlets. Because the material trajectory is linear

motion, it is called linear screen or linear vibrating screen.

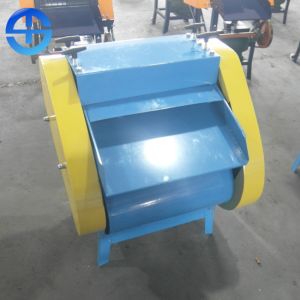

The small linear vibrating screen is mainly composed of screen box,

screen frame, screen, vibration motor, motor pedestal, damping

spring, support, etc.

1. Screen box: welded by several kinds of steel plates with

different thickness, with certain strength and stiffness, is the

main component of the screen machine.

2. Screen frame: made of pine or wood with small deformation,

mainly used to keep the screen smooth and reach normal screening.

3. Screen: low carbon steel, brass, bronze, stainless steel wire,

etc.

4. Vibration motor: (for operation and maintenance methods, please

refer to the operation manual of vibration motor).

5. Motor pedestal: when installing the vibration motor, the

connecting screw must be tightened before use, especially three

days before the trial use of the new screen machine, it must be

repeatedly tightened to avoid loosening and causing accidents.

6. Damping spring: prevent vibration from being transmitted to the

ground, and support all the weight of screen box. When installing,

the spring must be perpendicular to the ground.

7. Support: it is composed of four pillars and two channel steel,

supporting the screen box. When installing, the support must be

vertical to the ground, and the channel steel under the two pillars

should be parallel to each other.

Characteristics

1. Screen machine design, delicate and easy to assemble, one person

can operate the screen machine.

2. Compared with other related brand manufacturers, it has large

screening area and high efficiency processing capacity..

3. Unique screen structure design, convenient and fast screen

change (only 3 to 5 minutes), in addition, this design allows the

use of a variety of screens (nylon, special dragon, PP mesh).

4. The mother net fully supports the fine net, so the fine net can

have a longer service life, and reduce the use of the fine mesh

consumables, and the production process with a long deposition time

can reduce many costs.

Technical parameters

| Model | Size | Power | Weight |

| TMS-01 | 350*1200mm | 0.12kw | 80kg |

| TMS-02 | 600*1900mm | 0.18kw | 200kg |

| TMS-03 | 800*2000mm | 0.4kw | 280kg |

Use and Maintenance

1. The machine should be equipped with electrical protection

device.

2. At the beginning of the machine operation, check the anchor

bolts at least once a day to prevent loosening.

3. When the motor rotation direction does not meet the

requirements, adjust the power phase sequence.

4. When the machine is used again after a long time, the insulation

resistance should be measured, which should be greater than 0.5

megohm when it is used for 500 V megohmmeter measurement.

5. After 1500 hours of operation, the bearing should be checked and

replaced immediately if there is serious damage.

6. The motor should be well lubricated. Lithium grease (zl-3)

should be added once every two weeks or so. When adding oil, proper

amount of lithium base grease should be added through the oil cup.

When sealed bearings are used, the motor is not equipped with an

oil cup.