Inner Suction A Flute Hard Chrome Corrugated Roller Steam Heating

Introduction:

--The largest professional corrugated roller manufacturer in

northern of China

--50CrMo refined forging steel supplied by the best manufacturer in

China.

--A, C, B, E, F, G, N flute corrugated rolls

--High Speed can reach to 200m/min

--Hard Chrome 0.06-0.08mm

--Medium frequency quenching heating treatment machine makes --the

hardness of base steel more than HRC58 and harden layer 8-12mm.

--High precision and high performance CNC grinding machine equipped

with Germany Siemens control system.

--We design the flute profile according to customer’s medium paper

GSM, speed, FCT requirement. The flute profile is more reasonable,

suitable to customer’s machine

--Our corrugated rollers has been exported to many countries such

as Korea, Russia, Egypt, India, Thailand, Myanmar, etc.

--Supply corrugated rollers for all kinds of corrugator line such

as Fosber, BHS, BW Paper System, K&H, HSIEH HSU,Fuli, Wanlian,

TCY, Champion, West River, Mingwei and so on.

1. Strict Selection High Quality Material

50CrMo alloy steel is specialized material for manufacturing

corrugating rolls. Our raw material shell thickness is more than

70mm, the thicker shell can reduce deformation and keep stability

during production.

2. Precision Welding Can Be Inseparable

Both ends of the roller body should be heated to release the size

of the inner bored hole. After the spindle heads are put in, the

roller body and the spindle heads should be held tightly after

natural cooling.When the welding process finished, the work piece

shall be put into the furnace for high temperature tempering to

reduce stress.

3.High Hardness from Vertical Quenching Process

Intermediate frequency quenching can guarantee both the hardness

and harden depth we need. Our harden layer depth can reach to

8-12mm. With harder base material as foundation, the lifetime of

our corrugating rolls are greatly extended. After different heat

treatment process, the corrugated roller surface becomes more

wear-resistant and durable. After heating treatment we cut slots of

lower roll though this process needs more time but makes uniform

hardness.

.

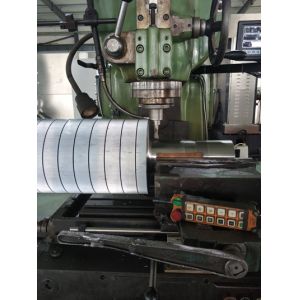

4. Rigorous for Precise Grinding

After heat treatment and the cutting slots, the roller shall be put

on high precision automatic CNC grinding machine to do finish

grinding. By grinding wheel grind each flute several times until

the accuracy is within our technical permitted requirement. The

Siemens control system play a key role in guarantee the accuracy.

5. Flute Profile

Almost every set of corrugating rolls are needed to be designed and

customized separately according to the width, diameter, flute

height, corrugated paper GSM, speed and cardboard physical index

requirement.

| Flute | Profile | Height(mm) | Pitch(mm) | Flutes/300mm | T.U.R |

| A | UV | 4.5-5.0 | 8.0-9.5 | 34±3 | 1.45-1.52 |

| C | UV | 3.5-4.0 | 6.8-7.9 | 41±3 | 1.37-1.47 |

| B | UV | 2.5-3.0 | 5.5-6.5 | 50±4 | 1.33-1.41 |

| E | UV | 1.1-2.0 | 3.0-3.5 | 93±6 | 1.24-1.36 |

| F | UV | 0.8-1.0 | 2.2-3.2 | 115±20 | 1.19-1.25 |

| G | UV | 0.6-0.8 | 1.8-2.8 | 136±20 | 1.15-1.20 |

| N | UV | 0.4-0.6 | 1.2-2.2 | 193±55 | 1.10-1.15 |

| Others | UV | Customized | Design | Design | Design |

6.Strict Test to Keep Improving

Before and after the surface treatment including tungsten carbide

plating or hard chrome coating of corrugating rolls, it is needed

to check the size, hardness, precision, flute profile, and

simulation feeding paper. Special projector is used to check the

flute profile and feeding different GSM paper to ensure the

performance of corrugating rolls.

Contact me:

Bonnie Li

Mobile&whatsapp&Wechat: +86-18661680180

E-mail: qdmjbonnie@hotmail.com, bonnenul@yahoo.com