Lenght 1400mm UAV Parts Alloy Steel HRC50 Cnc Milling Components

For Aircraft

Lenght 1400mm Heat Treatment HRC50 CNC Milling Custom Unmanned

aerial vehicle parts

UAV parts Aircraft parts

Material: 30Crmn Surface:etc Concentricity:0.01mm

Rugosity:Ra0.8 Tolerance:0.01-0.03mm Flatness:0.1mm

L*W*H(mm)=1400mm*80mm*30mm, Heat Treatment=HRC50

Metal:Titanium

TC4,TA9,TW340,AL2012,AL2A12,AL6082,AL6061,AL7075,SUS303,SUS304,30CrMn.

Machine:CNC machinging center,CNC lathe,Wire cutting macine,Milling

machine,Grinding machine,EDM.

Surface treatment:sand blast,,anodizing,Engraving,Gold plating.

Purpose:unmanned aerial vehicle,drone,

UAV,UUV,Aerospace,Defense,Aircraft,guided missile,Submarine,

Navigation, military.

Main Products Display

Processing all kinds of metal and plastic matenrials with the

change of the times,the materials chosen by

customers are changing constantly,in order to meet the different

material needs of customers,we have

accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical

processing of metal and non-metal materials through continuous

technological innovation and research

and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic |

| 1.2344 | SUS303 | A1050 | C1020 | PC |

| SUJ2 | SUS304 | A2017 | C1100 | PP |

| 1095 | SUS316 | A2024 | C145 | MC |

| 1212 | SUS403 | A5056 | C147 | POM |

| 1566 | SUS416 | A5052 | C5191 | ABS |

| S355 | SUS420J2 | A6020 | C1220 | PVC |

| C45 | SUS630 | A6063 | Others | PMMA |

| F125 | 17-4PH | A6082 | | Bakelite |

| F141 | | A7075 | | Teflon |

| CK45 | | Others | | Others |

| Others | | | | |

| Heat Treatment |

| treatment | Conditioning treatment | High cycle quenching |

| Passivation | quenching treatment | Carburizing treatment |

| Stress Removal Passivation | Vacuum quenching treatment | salt-bath nitrocarburizing |

| Annealing treatment | Tempering | |

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring

you the most reliable,efficient and affordable metal component.our

highly skilled and professional workforce is dedicated to

satisfying the individual needs of all our customers and various

markets the serve. |

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Quality policy

With the rapid development of global economy, competition and

challenges in various fields have become

inevitable. We are adhering to the firm spirit of enterprise and

constantly pursue innovation, and are brave

enough to face and overcome all kinds of severe test.My team is

consistently innovating and developing

our capability to align and meet the ever-changing market dynamics

and technology advancement,

in providing efficient supply-chain &cost efficiency to our

customers for their end—users. we strongly

believe in creating“win-win”synergy with our customers to build a

long—term strategic partnership for

mutual growth.

To focus on "customer satisfaction" as the premise condition of

core business tenet, company personnel

to promote lean production management mode. With the evolution and

development of precision metal

parts manufacturing industry chain, we recognized that the

industrial chain of enterprise survival based

on quality and product services to guests. To this end, we continue

to introduce foreign high-precision

processing and testing equipment; product process simple optimizing

continuously; constantly improve

product quality standards and other aspects of enterprise

management innovation, the company has

won high praise and affirmation from customers.

Xinya precision — professional Precision metal parts industry for

more than ten years

Continuously provide for you quality and speed try our best do

everything

Customer's requirement is our standard. In the long-term production

process, we have

established a perfect quality management system, so that product

quality can be controlled

steadily in the manufacturing process. We strictly enforce the

operation rules and quality

standards from the aspects of material purchasing, R&D and

design, process flow and

quality inspection, all of which originate from our unremitting

pursuit of quality.

We can't give you the lowest price, we can only give you good

quality. We would rather

explain the price to you for a while than apologize for the quality

for a lifetime. If we only

want to pursue profits, we can achieve the goal of fast sales by

reducing costs. But we think

that only perfect quality is our pride, in order to promise that we

will not be proud of

short-term benefits. Selling the future, our efforts and

persistence are recognized and

followed by more and more customers, which is the greatest driving

force for us to continue

to move forward. We can not thank you, but only report quality.

| Quality Inspection Links and Inspection Items | Introduction of Various Quality Testing Instruments |

| 1.Inspection of raw materials | 3CMM |

| IQC Inspectors will inspect surface,size and matcertificate

provided of materials. |  | CMM can be defined as "a detector which can move in three

directions. |  |

▼ ▼

| 2.First sample inspection | 3CMM |

| Technicians and quality personnel will carry out self-inspection of

the first sample, Batch production can not begin until the full

size is qualified |  | Meanwhile length, width,height, verticality, parallelism,

cylindricity and contour accuracy can be measured. |  |

▼ ▼

| 3.Process Inspection & Circuit Inspection | 2.5CMM |

| IPQC-checked regularly After start of mass production, we can find

out influence of mechanical equipment changes and tool wear on size

in time. |  | Usually takes the image into the computer through CCD for

measurement and calculation. |  |

▼ ▼

| 4.Air tightness check, water pressure check | High Altimeterr |

| If you have assembled parts of product and required to inspect

withstand pressure and leak inspection, we can do it. |  | High Altimeter (also known as altimeter) is used to measure the

height of space points relative to the ground. |  |

▼ ▼

| 5.Final Inspection of Manufacturing Process | Micrometer | Calipers |

| FQC is abnormal, it will be considered there is a quality problem

between the inspection tour to final product. the FQC is an

important link to ensure quality. |  |  |  |

▼ ▼

| 6.Full inspection of appearance and key dimensions | Comparator | Inner diameter micrometer |

| All finished products will be inspected for scratches, bruises,

debris, threads, burrs and other appearance problems. |  |  |  |

▼ ▼

| 7.Over Quantity Check | Pin gauge,block gaugeT | hread gauge, pass gauge |

| OQC will carry out strict inspection according to drawings and

quantity order. This inspection is also the last defensive wall to

prevent the flow of defective products. |  |  |  |

▼ ▼

| 8. Fill in the quality inspection report | Material Sheet | Quality inspection report |

| The results of actual measurement are collated and the quality

inspection report is made. Delivery with goods to customers. |  |  |  |

▼ ▼

| 9. Packing | Rohs report | MSDS Sheet |

| Finally, it is packed into special cartons or composite boxes to

arrange related logistics and transportation |  |  |  |

Our measuring equipment:

CMM

Projector

Concentricity measurement

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Vernier Caliper

Roughness machine

Our precision machined components are implemented of

ISO9001:2015,combined with

our in-house quality control system and these measuring

equipments,ensure problem-free

products.

Why are you choose us ?

1. Rich CNC machining experience.

XINYA was founded in 2008years, having a long history of 10

years.full experience accumulated in

Precision CNC machining service on best quality for medical,

communications, photoelectric, auto parts

processing,CNC Precision machining. Mechanical processing - heat

treatment - surface treatment and

assembly, we are committed to offer you and one-stop solution .

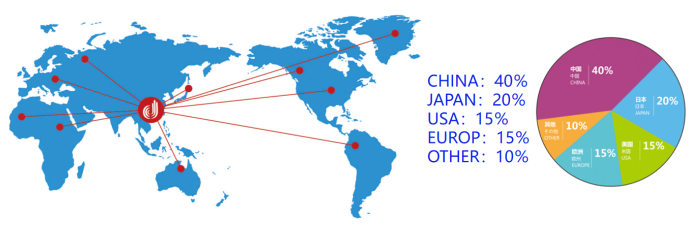

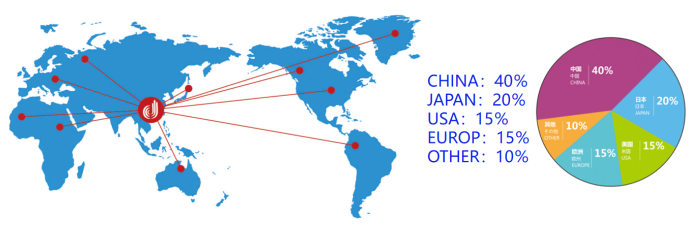

2. We have do business with many foreign customers from

Europe/North America/Aisa etc areas, like we

have cooperation with GE and SUMITOMO,CANON for around 10years. No

matter how much the production

is, we will take it seriously and do our best.

3. We have had 60 sets machining,including CNC automatic lathes

imported from Japan,

So this will help our company have bigger manufacturing capacity.To

meet more customers'

precision request, we have CMM, PROJECTOR etc.Precision inspection

instruments to

measuring our products.In order to ensure quality, we carry out

strict first sample inspection,

processinspection, shipment inspection, and every process is

strictly checked. We try every

means to prevent defective products from flowing into the next

process and customer place.

4. We offer OEM/ODM service with reasonable production techniques

for customers to cut down the

cost. Our engineering team use the UG/PROE/SOLIDWORKS/MASTER etc

software to support

our production techniques.

5. Overseas logistics experience, FOB, CIF, DAP and other trade

terms.

It is our goal to meet our customers’ expectation through good

quality, fast delivery service, productivity and

Continuous improvement.Shenzhen Xinya Precsion machining Co., Ltd

is to be your best choiceand long-term

partner.

FAQ:

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension,

tolerance, surface treatment and other

technical requirement etc.) ,quantity, application or samples. Then

we will quote the best price within24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs for cnc machining parts,

besides,we welcome trial order before

mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical

requirements and quantity. We always try to

meet customers' requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A: T/T, Alipay, paypal, western union, moneygram etc.

Q: Is it possible to know how is my product going on without

visiting your company?

A: We will offer a detailed products schedule and send weekly

reports with digital pictures and videos

which show the machining progress.

Q: If you make poor quality goods,will you refund our payment?

A: We make products according to drawings or samples strictly until

them reach your 100% satisfaction.

And actually we wont take a chance to do poor quality products.We

are proud of keeping the spirit of good quality.

If you have any further questions, please just feel free to contact

me directly. I will try my best to service you

and your company. I hope we will be a good cooperation in the

futuue.

Marketr and Service

We Are Committed To Fulfilling Your Needs,We Are Proud Of Your

Every Success