customized high precision refractory ceramic sandblasting nozzles

for tig welding

Alumina ceramics, Al2o3 ceramics, has the advantages of high

melting point and boiling point, high hardness, insulation at normal temperature, and electrical conductivity at high

temperature.

Alumina Ceramic tube has exceptional hardness and strength, resistance to chemical

attack and wear, low dielectric loss and excellent electrical insulation properties. Additionally,

Alumina can be metallized for brazing to other metals, highly polished, and comes in a variety of purities depending on it use.

Due to these outstanding properties ceramic Alumina tubes are used in a wide range of industrial and advanced applications.

1) A variety of specifications available.

2) Satisfy various technical request

3) High quality be sure

4) Good insulation performance and high temperature resistance

5) Bending strength and compressive strength resistance

6) Used in all electric products and electric heating products

7) OEM, ODM and OBM are welcomed

1) Material:

a) 95% Al2O3

b) 99.5% Al2O3

c) ZrO2

2) Surface finish:

a) Normal polish Ra 08-1.0μm

b) Fine polish Ra 0.4-0.6μm

c) Diamond polish Ra 0.2μm

3) Properties:

a) Wear resistant

b) Corrosion resistant

c) Heat resistant .

d) Stable dimensions

e) Lightweight ,

f) Long performance life

g)favourable price and shortest delivery

Description

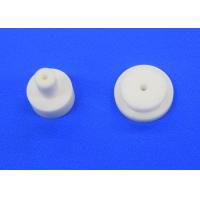

1. Name:ceramic plunger

2. Size: customize

3. Grade: 95-99 grade

4. Raw material:95%/99% alumina

5. Color:white or ivory

6.Working temperature:1500-1700

7.Feature:refractory,wear resistance,high strength and so on.

8.Purpose:used in machinery,textile,electricity,solar energy

,mobile phone,construction industry ,etc

We can offer the products base on customer's drawing, sample and

other reference parameter

Properties Sheet:

Material Properties:

| 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | Silicon nitride | Aluminum nitride | Machinable ceramic |

| Colour | white | Light yellow | white | black | black | gray | white |

| Density (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 | 2.48g/cm3 |

| Water Absorption | 0 % | 0 % | 0 % | 0 % | 0 % | 0 % | 0 % |

| Hardness(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - | - |

| Flexural Strength(MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa | 91MPa |

| Compressive Strength(MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - | 340MPa |

| Young's Modulus Of Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310~350GPa | 65GPa |

| Poisson's Ratio | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 | 0.29 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C | 1.46W/m°C |

| Dielectric Strength | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Volume Resistivity(25ºC) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm |

This data is typical for laboratory testing and the actual

characteristics of a particular production batch may vary.

Machining Accuracy

(1) Axis: roundness 0.002 mm, concentricity 0.002 mm, smoothness

Ra0.1;

(2) Hole: the minimum processing hole diameter is 0.2 mm and the

depth is up to 6 mm (depending on the material);

(3) Slot (seam): a minimum of 0.1 mm narrow groove, and grooves of

various shapes;

(4) Plane: 0.1MM sheet with minimum processable thickness,

parallelism 0.001mm, measurement tolerance 0.001 mm, finish Ra0.1;

(5) Thread: The minimum Machinable M2 internal thread, the accuracy

of GB-7h, the external thread size is not limited, the accuracy is

GB-6g.

Product show

Package and shipping

High al2o3 tube insulators will be packed in a bubble bag

individually, then separated by a foam, finally put in standard

export carton packing, or OEM packing.

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or Sea

transportation.

Company information

Who Are We?

Mingrui has professional OEM experience in manufacturing industrial ceramic parts for so many

years. We can make the products according to your drawings, custom the size,

thickness and other parameters.

What Do We Do?

We have very advanced technologies in the production of zirconia and alumina ceramic nozzle, rod, ring, tube, shaft, plate,

sleeve, valve, plunger, bearing, and semiconductive ceramics etc.. They are applicable to Electrical, Appliance, Mining, Oil & Gas,

Energy & Power, Food & Medical, Agriculture, Aerospace,

even other High-end fields.

Our products with some certificates, such as , CE, TUV, etc..

Factory information

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.