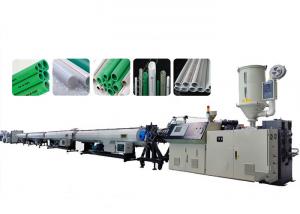

PPR Plastic Pipe Extrusion Line , Automatic Cold / Hot Water Pipes

Production

Product description:

PPR Pipe production Line mainly used in the production of PPR

cold/hot water pipes. In the same Production Line of PPR, it can

also applied to

produce PP, PE, PB and PPRC pipes. This line is available to use

single extruder to make monochrome pipe, or use multiple extruders

to make

multi-layer color pipe, or color line marked pipe. Equipped with

special screw and high quality reducer, have the characteristics of

stable extrusion and high-speed plasticization. This unit adopts combined spiral

machine head; effectively remove the material memory function. In

addition, Vacuum calibration and constant temperature control eliminate the pipe

stress. The whole line is of compact structure, high degree of

automation and simple operation, so it is the ideal production equipment.

LB Machinery depends on design production experience of many years;

join the domestic and international actual circumstance, developed

full-automatic production line, which from extruder including all

automation units and peripherals, whole production line realizes

automatic control from charging to finished product.

Technical parameter:

| Type | Pipe Spec(mm) | Extruder | Max. output (kg/h) |

| PE63 | φ20-φ63 | SJ-45/30 SJ-25/25 | 120 |

| PE160 | φ63-φ160 | SJ-60/30 SJ-25/25 | 300 |

| PE250 | φ75-φ250 | SJ-75/30 SJ-25/25 | 400 |

| PE450 | φ160-φ450 | SJ-90/30 SJ-25/25 | 600 |

| PE630 | φ315-φ630 | SJ-120/30 SJ-25/25 | 800 |

| PE800 | φ450-φ800 | SJ-150/30 SJ-25/25 | 1000 |

| PE1200 | φ710-φ1200 | SJ-150/33 SJ-25/25 | 1300 |

PPR pipe production line, PPR plastic pipe making machineprocess:

Material + Color Master-batch → Mixing → Vacuum Loading → Raw

Material Drying → Single Screw Extruder → Color Line Extruder →

Mold → Vacuum Forming Tank → Spray Cooling Water Tank → Crawler

Haul-Off → Planetary Cutter→ Stacker → Completed Product Inspection

& Packaging

Feeder

The Feeder used to feed material into the extruder, usually using a

vacuum feeder to feed pellets into the extruder.

Single Screw Extruder

Usually recommends two single screw extruders in this case: the

larger extruder used to extrude the actual pipes while the smaller

extruder used to extrude the colored mark line. This is the

integral part of the entire extrusion line and Yurefon only uses

the finest quality extruders to insure reliability and performance.

Mould (Die Head)

The mould is another essential part of the HDPE extrusion line.

Mould defines the shape and diameter of the PE pipes. The quality

of the extruded pipes are largely depending on quality of the mold

(die head).

Vacuum Calibrating and Cooling Tanks

High quality Vacuum calibration and the cooling tanks give produced

PE pipes a better looking exterior. An extra set of vacuum

calibrators and cooling tanks are required when extruding pipes

with larger diameters.

Water Cooling Tanks

The pipes extruded from the mould (die head) is extremely hot. Even

after going through vacuum calibration and the cooling tanks, they

will still need to be further cool. The water cooling tanks in this

case further cool down the pipe through water. Usually, the larger

the diameter of the pipes been extruded, the larger the

water-cooling tank will need to be.

Haul-off Unit

The Haul-off unit used to move the pipe forward, the particular

make and model of the haul-off unit depends on the quantity of the

claws.

Cutter

LB ’s pipe machine cutter completed automated and controlled

digitally. The interface designed for ease to use and with great

performance in mind.

Winder or Stacker

A winder used in smaller diameter PE pipes production, those small

diameter PE pipes are flexible enough to coil around a winder, and

thus

essentially allow unlimited length for produced pipe.

A stacker is recommended in larger diameter case, usually above 63

mm, in this case produced PE pipes are stacked together efficiently

on stacker, waiting for final packaging and transportation.