New high quality middle sized easy to operate bag Type Dust

Collector

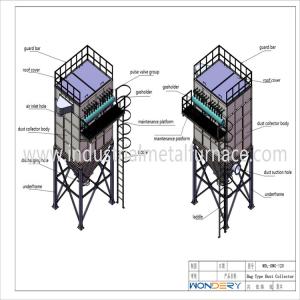

1. Application

This equipment is for the treatment of high-temperature flue gas.

The treatment system adopts two-grade dust removal. The first grade

adopts high-efficiency dust collector, which is mainly used to

treat the

coarse particle produced during melting in aluminum melting

furnaces,

and has great cooling effect. The second grade adopts

high-efficiency

pulse dust removal bag dust collector, which can filter the dust up

to 99.5%,

meeting the national emission standard requirement. The treatment

air

volume of the dust removal system is 17000 m3 / h.

Determination of the filter area of the dust collector: the filter

wind speed is

1.5m/min, the filter area is 15m2, and the dust collector adopts

pulse

anti condensation pulse bag filter.

2. Working Principle

2.1 The dust collector is of anti condensation pulse type dust

collector.

2.2 The dust collector is of single row design, with 120 filter

bags and

a total filtration area of 15m2.

2.3 The filter bag adopts the standard size of φ 130 × 2000, and

the

material is anti condensation polyester needle felt.

2.4 The external filter type is adopted for the dust collector, and

the filter

bag of the dust collector is connected with the riffled plate by

the spring

expansion ring, forming the separation between the air and the

dusty gas.

2.5 The pulse signal is sent to the pulse solenoid valve by the

pulse controller,

and the pulse solenoid valve ejects compressed air to make the

filter bag

radial deformation and shake off dust.

2.6 There is an access door on the top of the dust collector, which

is used

for maintenance and bag change (the maintenance, repair and bag

change

of the dust collector can be carried outside the machine, without

entering

the inside of the dust collector).

2.7 The electric control cabinet of the dust collector adopts the

structure of

sealed door, which is dust-proof, and waterproof.

2.8 In order to prevent the high temperature of flue gas entering

the dust

remover, a temperature measuring point is set on the dust remover

pipe.

The temperature indicator is installed at the operation point of

the furnace

and equipped with an alarm device to remind the operator that the

temperature

rise of the dust remover is too high and take fresh air supplement

measure to

ensure the safe operation of the whole dust removal system.

2.9 fan selection: according to the design air volume of the

system, 1 set of

G4-73-10D boiler induced draft fan is adopted, with single total

pressure of

3251-3018pa, air volume of 25566-32083m3 / h, motor of Y150M-4 and

power of 18.5kw.

2.10 system control: according to the process requirements of the

system,

a control cabinet is set for the dust collector and temperature

control system

to control the pulse dust cleaning system and temperature

monitoring of the

dust collector, and the main fan is started by frequency converter.

3. Equipment Features

3.1 Anti condensation pulse bag filter is a kind of unit combined

dust removal

equipment with large air volume, low filtering wind speed, good

dust removal

effect, high dust removal efficiency, reliable operation,

convenient maintenance

and small floor area. Modular production, stable quality.

3.2 Working principle: The dust collector is composed of upper box,

middle box,

ash hopper, guide plate, support, filter bag component, injection

device, protection

system, control system, etc. The dusty gas enters the ash hopper

through the

diversion pipe. Under the guidance of the diversion system of the

ash hopper,

the large particle dust directly falls into the ash hopper after

separation, and the

rest of the dust enters the filtering area of the middle box with

the air flow. The

filtered clean gas is discharged through the upper box and the

exhaust pipe

through the filter bag. With the progress of the filtering

condition, when the dust

on the surface of the filter bag reaches a certain amount, the dust

cleaning control

device will open the electromagnetic pulse valve for injection

according to the set

procedure to shake off the dust on the filter bag. The dust falling

into the ash

hopper is discharged through the ash discharge valve.

3.3 The filter area and length can be adjusted. The quantity of

filter-bag can be

changed to adapt to the needed air volume.

3.4 The anti-condensation pulse bag filter is an external filter.

The dust-containing

gas is outside the filter bag while the clean air is inside the

filter bag, and the bag

mouth is upward. Start pulse jetting making the bag radial

deformation, and

shake off the dust.

3.5 The dust collector adopts the online ash cleaning method.

3.6 The secondary air distribution method is adopted to let the

dust-laden air flow into

the filter area through the guide pipe and the air distribution

system, which ensures

the uniformity and smoothness of the unit air intake, so as to

improve the utilization

ratio of the filter area and the service life of the filter

material.

3.7 The filter bag adopts the spring expansion ring type with a

good sealing

performance and a fast replacement speed. Open the top cover and

replace

the bag by 1-2 people.

3.8 The bag framework adopts a star-shaped structure (10 ribs) with

a η-shaped

cold stamping short pipe on the top to ensure the vertical

positionof the bag frame

and to protect the safety of the filter bag mouth during injection.

It avoids the filter

bag sticking after the dust collector works for a period of time,

ensures the smooth

change of the bag, and reduces the damage to the bag in the process

of changing the bag.

3.9 The dust collector adopts a removable roof and a platform for

maintenance and

escalator, which is convenient for personnel to overhaul, use and

manage.

4. Key components

4.1 For the whole dust collector, the filter bag and

electromagnetic pulse valve

are the key components.

4.2 The quality of the filter material directly affects the dust

removal efficiency of

the dust collector, and the life of the filter bag directly affects

the operation cost of

the dust collector. Therefore, the anti condensation polyester

needle felt is selected

according to the operation environment and medium conditions of the

dust collector.

This filter material is surface filtering material, which can clean

the dust thoroughly,

reducing the possibility of dust hardening after dust is

distributed on the surface of

the filter bag, and the filter material has a long life. In

addition, we have improved

the structure of the dust collector to ensure that the service life

of the filter material

is not less than two years.

4.3 The imported diaphragm is selected for the electromagnetic

pulse valve, and

the injection pressure is 0.5-0.7mpa. The diaphragm is durable, and

its service life

is more than 1 million times, which meets the requirements of

efficient operation of

the pulse solenoid valve.

5. Technical Parameter

| No. | Item | Unit | Parameter |

| 1 | Air volume | m3/h | 17000 |

| 3 | Efficiency of dust collection | % | ≥99.5 |

| 4 | Total effective filter area | m2 | 15 |

| 5 | Filter speed ( normal operation) | m/min | 1.5 |

| 6 | Filter-bag specification | mm | φ130×2000 |

| 7 | Quantity of filter-bag for dust collector | pc | 120 |

| 8 | Material of filter-bag | | polyester needle felt with singeing and pressing |

| 9 | Inlet gas temperature | | ≦100℃ |

| 10 | Equipment resistance | Pa | 1200 |

| 11 | Pulse valve quantity | pc | 12 |

6.Post Sales Service

Product warranty period: 13 months from the date of shipment. The

seller is responsible

for repairing the equipment or replacing the broken parts if faults

are caused by manufacture

defects, but damages caused by faulty operation by the workers are

to be repaired by the buyer

itself or by the seller at a certain rate of charge. (Easy-worn

parts, and natural consumption

of high temperature parts are not included in the warranty.)