In modern manufacturing, the processing of small plastic parts plays a crucial role across industries such as electronics, medical devices, automotive, consumer goods, and aerospace. These tiny components—despite their size—often perform essential functions, requiring exact dimensions, consistent quality, and high-performance material properties. Their production demands advanced techniques, strict quality control, and a deep understanding of plastics and micro-fabrication.

Why Small Plastic Parts Matter

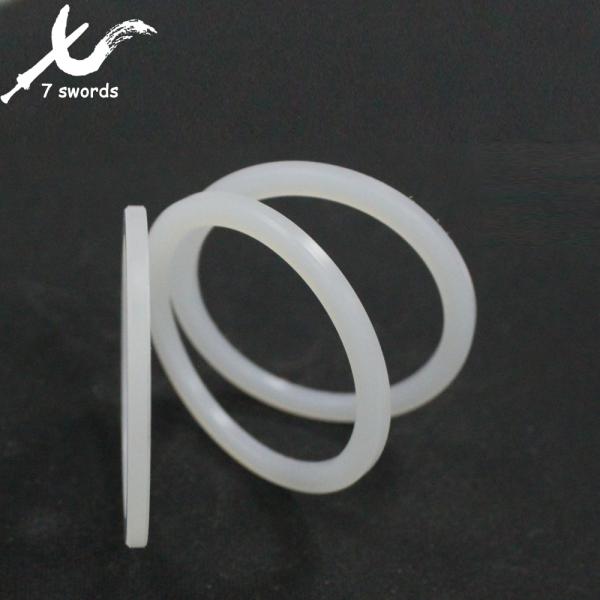

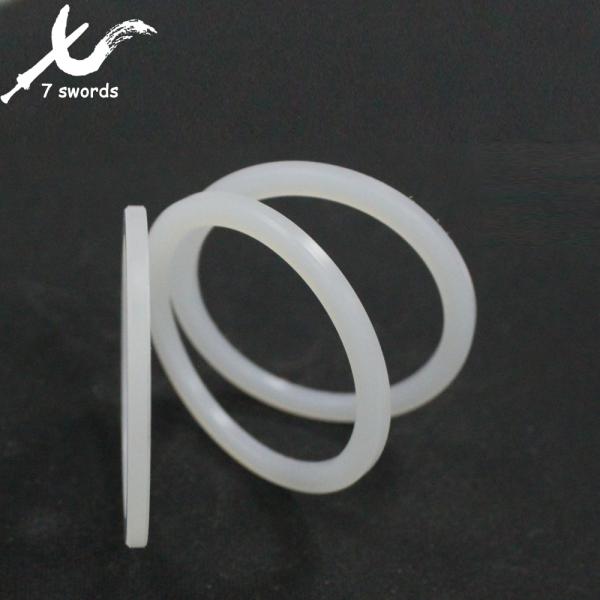

Small plastic components are indispensable in modern assemblies, from connectors and fasteners to seals, gears, spacers, and miniature housings. These parts must often meet tight tolerances, withstand environmental stress, and integrate seamlessly into complex mechanical or electronic systems.

Their advantages include:

- Lightweight properties

- Cost-effective material options

- High chemical resistance

- Electrical insulation

- Design flexibility and easy molding

Key Processing Methods for Small Plastic Parts

Several specialized manufacturing processes are used for fabricating small plastic parts, each suited to different requirements of volume, geometry, and material.

1. Injection Molding

The most widely used method, injection molding, involves melting plastic pellets and injecting them into a precision steel mold. Once cooled, the mold opens, and the finished part is ejected.

Advantages:

- Ideal for high-volume production

- Excellent repeatability and surface finish

- Supports complex geometries and fine details

Micro-injection molding, a variant of this process, is specifically designed for extremely small or detailed plastic parts.

2. CNC Machining

CNC machining of plastics is a subtractive process where plastic stock is milled, turned, or drilled using computer-controlled tools.

Best for:

- Prototypes and small-batch production

- Engineering-grade plastics like PEEK, Delrin, or PTFE

- Applications requiring tight tolerances or unique features

3. 3D Printing (Additive Manufacturing)

For prototyping or low-volume custom parts, 3D printing technologies like SLA, FDM, or SLS are highly effective.

Benefits:

- Fast turnaround for design testing

- Supports complex internal geometries

- Minimal material waste

4. Thermoforming and Vacuum Forming

While less common for very small parts, thermoforming can be used for thin-walled plastic components, particularly in packaging or lightweight enclosures.

Material Selection for Small Plastic Parts

Material choice significantly impacts a part’s durability, functionality, and cost. Common materials include:

- ABS: Strong, cost-effective, good impact resistance

- Nylon (PA): Durable, good wear and chemical resistance

- Polycarbonate (PC): High strength, clear, and heat-resistant

- POM (Delrin): Excellent dimensional stability and machinability

- PEEK: High-performance thermoplastic for demanding environments

- PVC: Good chemical resistance, widely used in connectors

Each material can be modified with fillers, colorants, or additives to meet specific requirements such as flame retardancy, UV resistance, or antistatic properties.

Challenges in Processing Small Plastic Parts

1. Precision and Tolerance Control

Small components require machining or molding to tolerances as tight as ±0.01 mm. Any deviation can lead to assembly failure or reduced performance.

2. Material Flow and Mold Design

In injection molding, ensuring uniform material flow into tiny mold cavities without creating defects like voids or flash is critical.

3. Handling and Inspection

Due to their size, small plastic parts are difficult to manually inspect and handle. Automated optical inspection systems and robotic pick-and-place technology are often used.

4. Tooling Cost vs. Production Volume

High-quality molds for small parts can be expensive. For low-volume runs, CNC machining or 3D printing may be more cost-effective.

Applications of Small Plastic Parts

These components are used in a wide range of products and systems:

- Medical: Catheter tips, micro valves, dental components

- Electronics: Connectors, buttons, insulating mounts

- Automotive: Dashboard switches, clips, wire harness components

- Consumer goods: Eyewear hinges, headphone components, appliance controls

- Aerospace: Lightweight clips, cable routing supports, sensor housings

Quality Assurance in Small Part Production

Due to their critical function and often tight tolerances, small plastic parts undergo rigorous quality control. Common techniques include:

- Coordinate Measuring Machines (CMM)

- Vision inspection systems

- Material testing (tensile, thermal, chemical)

- Statistical Process Control (SPC)

ISO-certified manufacturers often adhere to standards like ISO 9001, ISO 13485 (for medical), or IATF 16949 (for automotive) to ensure consistent quality.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.