Zhengzhou Iris Electromechanical Equipment Co., Ltd. is an

excellent supplier established in the Central Plains region,

adhering to the enterprise spirit of "professional foreign trade,

professional heating" and contributing to the overseas export of

China's industrial heating equipment. Our business scope includes:

KGPS series thyristor intermediate frequency heating equipment

(steel shell melting furnace, aluminum shell melting furnace,

heating furnace), two SCR series, parallel power supply, IGBT MF,

HF super audio heating equipment (melting furnace, forging furnace,

Quenching furnace, welding machine, heating furnace), resistance

furnace, CNC quenching machine tool, cooling system and auxiliary

transformer and other equipment.

Zhengzhou Iris Electromechanical Equipment Company was established

in 1989 and is located in Zhengzhou City, Henan Province, China. It

has two standardized modern workshops and an experimental building

with a construction area of 8,000 square meters. There are a

large number of professional technical research engineers,

including 12 technical engineers and 5 senior engineers.

Certificate

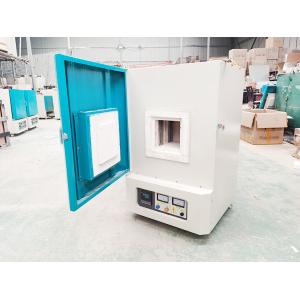

Work site example

The products of Zhengzhou IRIS Electromechanical Equipment

Company have been exported all over the world, such as Australia,

Russia, Italy, Vietnam, Singapore, Indonesia, the United States,

South Korea, Chile, Romania, Saudi Arabia, Nigeria, Kenya, and more

than 10 countries and area.