Zhengzhou ANNEC Industrial CO., Ltd. was founded at

Sep, 2003, and has been a NASDAQ listed corporation since

2011(Stock code: ANNC). ANNEC had become refractory industrial

leader provide core service such as refractory production,

technology of blast furnace and hot blast stove and EPC contract

project in China. Now ANNEC sets up Academician workstations, the

Provincial Engineering and Technology Center, Hot Blast Stove

Research Centre, ANNEC (Beijing) Engineering Technology Co., Ltd

and four production sites as subsidiaries. Yearly refractory output

is 150 kt.

ANNEC is a national hi-tech company, and is

accredited with ISO9001:2008 quality control system standards,

ISO12001:2004 environmental control system standards, and

GB/T28001-2011 HAZOPS. ANNEC has set up a thorough and effective

management system with practical considerations for her employees

and community, and is persistent in promoting employee self-value

and product products. Based on the efforts, ANNEC is the recipient

of the prestigious 2012 Zhengzhou Mayor Quality Prize.

ANNEC has capability of manufacturing refractories materials of

fireclay, high alumina, silica and insulating bricks and

corresponding unshaped refractories for hot blast stove. Meanwhile,

ANNEC also produce various refractories for coking, sintering,

casting house, torpedoes, iron ladles and steel ladles. ANNEC’s

products have been sold to America, Japan, Korea, India, Iran,

Vietnam, Turkey, Malaysia and Indonesia; get the customer's

endorsement in the domestic and world. At the same time, ANNEC’s

testing center shoulder examinations of products quality and tests

of new product development.

ANNEC has been providing matched refractories of

different type HBS for CERI, CISDI, WISDRI, CSGI and

Kalugin,P•W,Danieli and SIEMENS VAI in their worldwide projects.

ANNEC is awarded as excellent supplier by Baosteel, CSGI, and MCC

etc.

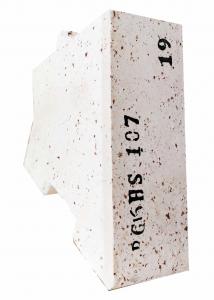

ANNEC owns more than 50 patent technologies which include checker

bricks with19 holes; 37 holes, 61 holes, ceramic burner of

swirl-cutting top combustion hot blast stove, cone-column

composited ceramic burner for top combustion hot blast stove,

symmetric layout structure of hot blast stove, three section hot

blast stove with independent structural. ANNEC was authorized to

fulfill editing 7 standards of national and of industrial,

including 《Silica Brick》, 《High Alumina Brick》, 《Refractory Brick

for HBS Ceramic Burner》,《Refractory Standard Configuration of HBS

System 》 and 《Energy Saving Technical Specification of Top

Combustion HBS》.

ANNEC successively get awards such as “Chinese

Outstanding S&T Innovation Enterprise”、“AAA grade Credit

Enterprise”“Chinese Famous Brand Trademark China” “Provincial

Famous-brand Product, Henan”“Provincial Credit Enterprise, Henan”

“Zhengzhou Environmental Enterprise”

ANNEC owns core culture which is to make customer

satisfaction, staff satisfaction and shareholder satisfaction; and

continuously push forward technological development of HBS and

progress of refractory technology by its great efforts, and

gradually becomes one of the best professional suppliers in high

temperature industry of global