Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment

Product Description

Precision Ceramics has years of experience designing and developing

technical ceramic solutions for a wide variety of applications and

industries. Low Coefficient Of Friction Alumina Ceramic Parts Laser

Welding Equipment. We offer this expertise to all of our customers

to ensure the best design and materials are chosen for their

specific application and needs. Low Coefficient Of Friction Alumina

Ceramic Parts Laser Welding Equipment, Typically, our custom

technical ceramic components and parts we supply are used for one

of three main reasons:

Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment

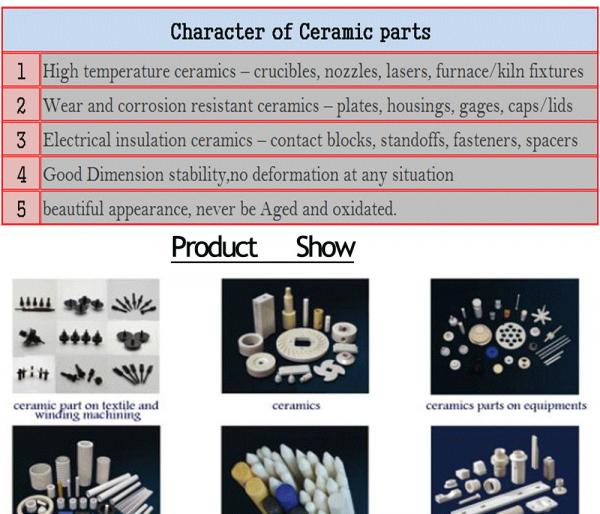

High temperature ceramics – crucibles, nozzles, lasers,

furnace/kiln fixtures

Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment

Wear and corrosion resistant ceramics – plates, housings, gages,

caps/lids

Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment

Electrical insulation ceramics – contact blocks, standoffs,

fasteners, spacers

Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment

Precision Ceramics is one of the world’s premiere technical ceramic

suppliers – contact us to see what technical ceramics we can create

for you.

Demand for advanced ceramic components will increase to more than

$12 billion in 2010, according to the Freedonia Group, an

international business research company in Cleveland, Ohio. Uses

for ceramics that are likely to grow include ballistic armor,

ceramic composite automotive brakes, aerospace diesel particulate

filters, joint replacement components, dental products and

piezoceramic sensors. In the meantime, electrical and electronic

applications such as insulators, igniters, heating elements, heat

shielding components, connectors, seals and magnets will continue

to be big consumers of advanced ceramics. Many of these

applications will require precision, multi-axis machining as an

essential part of the manufacturing process.

This bodes well for Superior Technical Ceramics in St. Albans,

Vermont. Machining advanced ceramics is one of the company’s

specialties. Superior machines ceramic workpieces in both the

"green" (unfired) and sintered (fired) states. Sintered workpieces

are much harder and denser than green ones and must be machined

with diamond grinding tools. Instead of using traditional grinders,

the shop often uses standard CNC milling machines and machining

centers for these grinding operations. One striking example is a

five-axis machining center used exclusively to produce the complex,

tightly toleranced geometry that fire-hardened workpieces require.

The volumetric accuracy of this machine has allowed the company to

bid on jobs involving features with tolerances as small as ±0.0002

inch (0.005 mm). This machine, a Vertex 550X-5X from Mitsui Seiki

(Franklin Lake, New Jersey), was installed in April 2008.

Industrial Ceramic Intriduction

Aluminium Oxide, Al2O3 is the most widely applied and cost

effective technical ceramic material. It offers a combination of

superior mechanical strength and electrical properties, wear

resistance and corrosion resistance. The maximum working

temperature is up to 1700 °C with relatively high thermal

conductivity. It is also an electrically insulating material with a

high electrical resistivity. The good corrosion resistance makes it

insoluble in water and slightly soluble in strong acid and alkaline

solution.

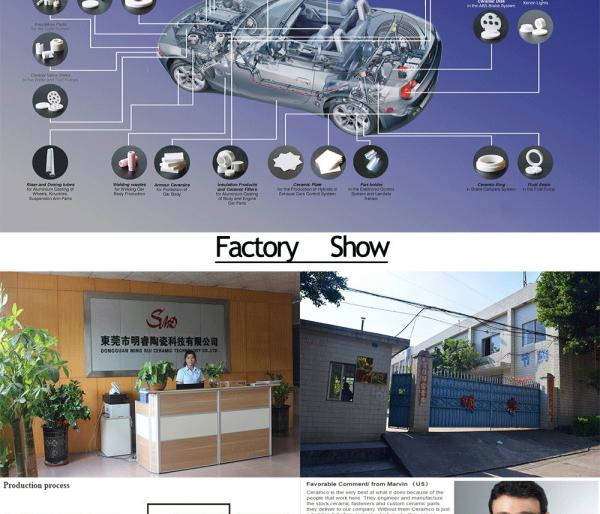

Company Introduction

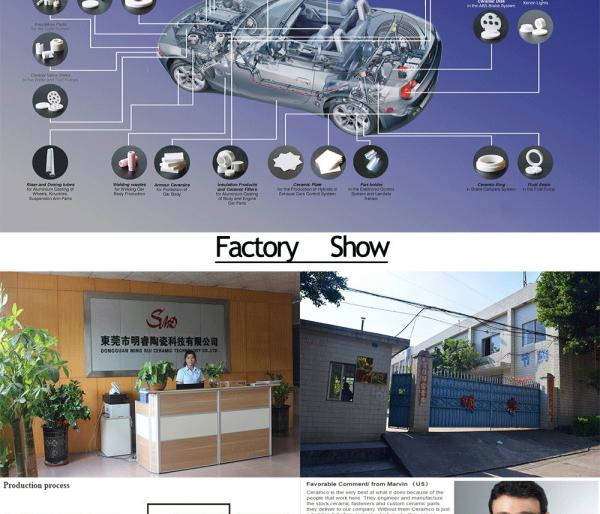

Mingrui ceramic manufacture and provides alumina ceramic components

for a wide range of application like Mechanical Equipment,

Electronic & Electrical, Oil Drilling, Medical, Chemical Industry

etc. According to actual application and customer's requirement,

the purities vary from 95%-99.7% and the forming methods will be

different. The forming methods applied in our plant include dry

pressing, isostatic pressing, injection moulding, extrusion

moulding. With experienced engineers and talented workers, we are

confident to offer high quality, high precision, complex components

for customers worldwide.

Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment

| General Characteristics of Materials: |

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium |

High

| low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Low Coefficient Of Friction Alumina Ceramic Parts Laser Welding

Equipment |

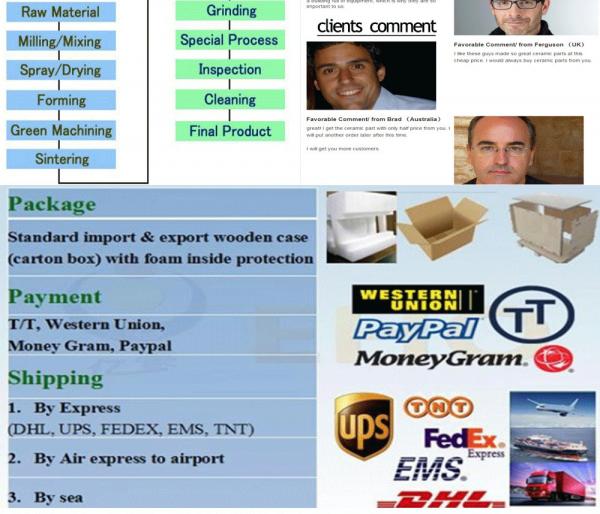

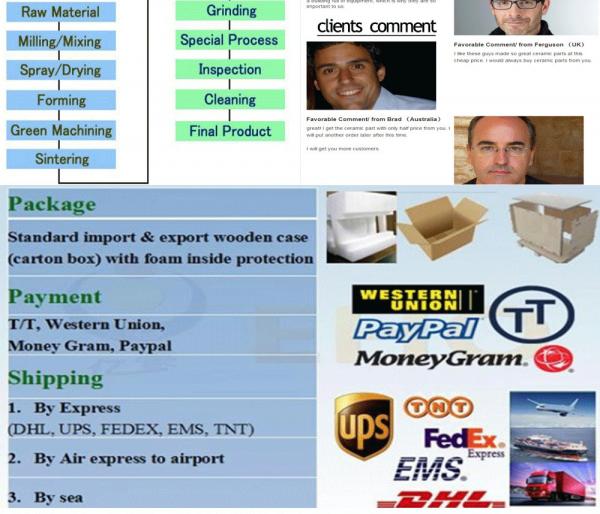

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .