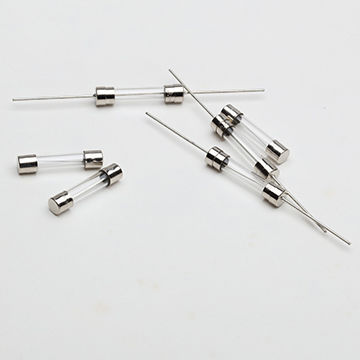

Cigar Lighter Cartridge Fuse Ferrule 6.35x32mm Time Delay Time Lag

Slow Blow Glass Tube Fuse 10Amp 250VAC 6x30mm

Overview

The Aolittel MTC Slo-Blo

w fuse solves a broad range of application requirements while

offering reliable performance and costeffective circuit protection.

Guesswork and time consuming circuit testing are eliminated. This

unique design offers the same quality performance characteristics

as the standard MTCSlo-Blow

Fuse design.

___________________________________________________________ Download________

Download________ Features

• In accordance with UL Standard 248-14

• Available in cartridge and axial lead format and with various

forming dimensions

• RoHS compliant and Lead-free

Application

Used as supplementary protection in appliance or utilization

equipment to provide individual protection for

components or internal circuits.

Specification

A=250V,B=125V

Part No. | Ampere Rating | Voltage Rating | Breaking Capacity | I2TMelting Integral(A2.S) |

|

| MTC0100A/B | 100mA | 250V/125V | 10000A@125 V AC (100mA~10A);

35A@250V AC (100mA~1A);

100A@250V AC (1.25A~3.5A);

200A@250V AC (4A~10A).

| 0.028 |

| MTC0160A/B | 160mA | 250V/125V | 0.075 |

| MTC0200A/B | 200mA | 250V/125V | 0.12 |

| MTC0250A/B | 250mA | 250V/125V | 0.15 |

| MTC0300A/B | 300mA | 250V/125V | 0.19 |

| MTC0315A/B | 315mA | 250V/125V | 0.22 |

| MTC0350A/B | 350mA | 250V/125V | 0.29 |

| MTC0400A/B | 400mA | 250V/125V | 0.28 |

| MTC0500A/B | 500mA | 250V/125V | 0.52 |

| MTC0630A/B | 630mA | 250V/125V | 0.87 |

| MTC0750A/B | 750mA | 250V/125V | 1.1 |

| MTC0800A/B | 800mA | 250V/125V | 1.4 |

| MTC1100A/B | 1A | 250V/125V | 3.5 |

| MTC1125A/B | 1.25A | 250V/125V | 7.6 |

| MTC1150A/B | 1.5A | 250V/125V | 9.1 |

| MTC1160A/B | 1.6A | 250V/125V | 13 |

| MTC1200A/B | 2A | 250V/125V | 20 |

| MTC1250A/B | 2.5A | 250V/125V | 39 |

| MTC1300A/B | 3A | 250V/125V | 61 |

| MTC1315A/B | 3.15A | 250V/125V | 56 |

| MTC1350A/B | 3.5A | 250V/125V | 70 |

| MTC1400A/B | 4A | 250V/125V | 104 |

| MTC1500A/B | 5A | 250V/125V | 148 |

| MTC1600A/B | 6A | 250V/125V | 173 |

| MTC1630A/B | 6.3A | 250V/125V | 192 |

| MTC1800A/B | 8A | 250V/125V | 380 |

| MTC2100A/B | 10A | 250V/125V | 580 |

| MTC2120A/B | 12A | 250V/125V | 723 |

| MTC2150A/B | 15A | 250V/125V | 934 |

| MTC2200A/B | 20A | 250V/125V | 1280 |

| MTC2250A/B | 25A | 250V/125V | 1678 |

| MTC2300A/B | 30A | 250V/125V | 2036 |

Electrical Characteristics by Series

% of Ampere Rating(In) | Blowing Time |

| 100%* In | 4 hours Min |

| 135%* In | 1 hour Max |

| 200%* In | 120 sec Max |

Dimension (mm)

Product Characteristics

| Material | Body: Glass Cap: Nickel–plated brass Leads: Tin–plated Copper |

| Terminal Strength | MIL-STD-202, Method 211, Test Condition A |

| Solderability | MIL-STD-202 method 208 |

| Product Marking | Cap1: Brand logo, current and voltage ratings Cap2: Series and agency approval marks |

| Operating Temperature | –55ºC to +125ºC |

| Thermal Shock | MIL-STD-202, Method 107, Test Condition B: (5 cycles -65°C to

+125°C) |

| Vibration | MIL-STD-202, Method 201 |

| Humidity | MIL-STD-202, Method 103, Test Condition A: High RH (95%) and

Elevated temperature (40°C) for 240 hours |

| Salt Spray | MIL- STD-202, Method 101, Test Condition B |

Difference Between Ceramic & Glass Fuses

A fuse protects electrical appliances and equipment by breaking the

electrical circuit in the event of an overload of current or a

short circuit. There are a number of different types of fuses

available, and these differ in size, shape and material. Ceramic

and glass are two common materials used to make fuses.

How Fuses Work

When a fault occurs, such as an overload or short circuit, the high

current that is flowing through the fuse melts the fuse element,

thus interrupting the flow of current and breaking the circuit.

This prevents the appliance from damage due to excess current.

History

The earliest fuses were no more than simple open wires introduced

in an electrical circuit to break the flow of current when

necessary. The first enclosed fuse was created by Edison in 1890.

Since then, the fuse has developed and diversified into many

different types.

Types

Though the purpose of all fuses, whether ceramic or glass, is the

same, each has a unique manner of functioning and a unique response

to an overload of current. The fuses available are very fast acting

fuses (FF), fast-acting or quick-blow fuses (F), medium-acting or

semi-delay fuses (M), slow-blow, time-lag or time-delay fuses (T)

and very-slow-acting, long-time-lag or super-time-lag fuses (TT).

Each fuse responds differently to current flow and surges, and

takes a different amount of time to react; it is therefore

important to choose the correct fuse for the circuit it is to be

introduced in. An incorrect fuse could either mean no protection

because it has not melted in time, or oversensitivity when it blows

repeatedly for no real reason. For example, if an FF fuse is fitted

in a circuit with an appliance that creates a current surge when it

is first switched on, the fuse would blow even though there is no

threat. Typically, for a 500 percent overload, an FF fuse would

take one-tenth the time of a normal F fuse to blow, while a T fuse

would take up to 200 times longer.

Construction

A fuse body is made of glass, ceramic, plastic or fiberglass. The

body is called the barrel, and it has a terminal made of plated

copper or brass at each end. These terminals are connected by the

fuse element, which is made of copper, aluminium, zinc, or silver.

The element could either be a single wire, or consist of more than

one wire. The multiple wires could be arranged in different ways to

make the fuse behave differently. Sometimes, sand or quartz powder

is filled in the body to alter the behavior of the fuse. This is

usually the case in a ceramic fuse.

Differences

In a glass fuse, the element is visible, and this makes inspection

easy, while a ceramic fuse is opaque. A glass fuse has a low

breaking or rupturing capacity. What this means is that the fuse

element melts when there is a high current or voltage. It is

therefore not suitable for appliances and equipments that draw a

lot of current. Ceramic fuses, on the other hand, have a high

breaking or rupturing capacity and are suitable for high current

and voltage circuits. Some ceramic HRC (high rupturing capacity)

fuses can safely interrupt upto 300,000 amperes of current, while

normal glass fuses have a much lower capacity, sometimes as low as

only 15 amperes.

Glass fuses have a low thermal stability and shatter in high-heat

conditions. Ceramic fuses, on the other hand, can withstand high

temperatures and are more thermally stable. Ceramic fuses, unlike

glass fuses, are also often filled with a filler like sand to

prevent the formation of a conductive film. When there is a short

circuit, the fuse element melts and vaporizes. It deposits on the

inside of the barrel or body as a film. In a glass fuse, the body

continues to get heated and the film begins to conduct electricity,

thus rendering the fuse inefficient. The sand in a ceramic fuse,

however, absorbs the heat energy and prevents the fuse from heating

and therefore conducting.

Considerations

It is important to consider these factors before installing a fuse:

the maximum continuous current rating, which indicates the maximum

current that can pass through a fuse; the rupturing or breaking

capacity, which indicates the maximum current that can be

interrupted without causing damage; the voltage rating--the fuse

must be used at less than the rated voltage.

Warning

Ensure you choose the right fuse for your appliances and equipment

to protect them and to reduce the risk of overheating and fire. If

you are unsure, speak to an electrician.

w fuse solves a broad range of application requirements while

offering reliable performance and costeffective circuit protection.

w fuse solves a broad range of application requirements while

offering reliable performance and costeffective circuit protection.