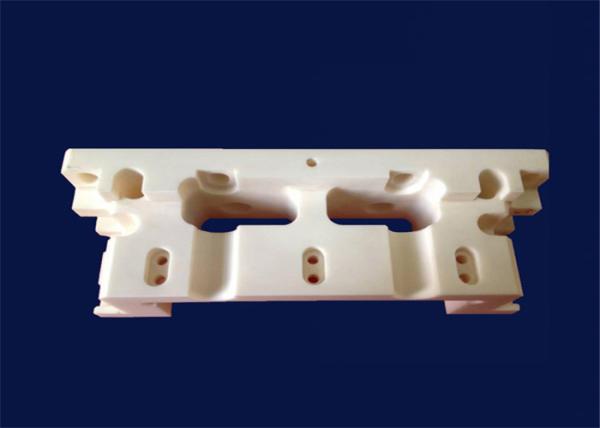

Insulating Precision Machinable Ceramic Block Machining Ceramic

Parts Drilling Hole

PRODUCT MATERIAL:

Alumina Ceramic or Zirconia Ceramic, for Alumina, the purity would

be 95% or 97% or 99.99%,

For Zirconia, the purity usually be 95% , the balance 5% sould be

additive material.

We also can provide electronic ceramics, the material is Aluminium

nitride , it is a very special ceramic material, there are both

excellent Electrical insulation and Thermal conductivity. This

Aluminium nitride ceramics widely be taken in electronic

application.

MACHINING EQUIPMENTS:

Surface Grinder

Lapping Polish Maching

Cylindrical Grinder

Centerless Grinding Machine

Milling Drilling Maching

Ultrasonic Machining

Laser Micro-Machining

DIMENSION:

MingRui Ceramic can make all the size as bellow:

shape in cylinder, diameter 0.3-100 mm, length up to 300 mm;

shape in plate, length and width up to 100 mm, thickness0.2-50 mm;

shape in through hole, Diameter 0.10-100 mm;

shape in blind hole, diameter 0.45-100 mm;

shape in Groove or slot, depth up to 50 mm, width 0.1 mm at least.

Typical for the applications of technical ceramic materials is a

frequent requirement for other non-electrical properties such as:

- Mechanical strength

- Thermal resistance

- Thermal shock resistance

- Thermal conductivity

- Corrosion resistance

- Production of ultrahigh-vacuum-capable joints with metals

A key strength of this class of materials is the demand-driven

combinations of the above-mentioned properties. In addition comes

the possibility to optimize properties for a specific application

by means of appropriate doping and therefore to tailor materials to

requirements.

For instance, the zirconia ceramics used for λ sensors can be

optimized to maximize their strength without compromising their

suitability for use as oxygen sensors as only one electrical signal

must be recorded, which can be evaluated on the basis of

appropriate calibration. With the selective modification of the

chemical composition of this material, maximized electrical

conductivity can be obtained along with an acceptable level of

strength. As a result, this anionic conductor can be efficiently

used as electrolyte for SOFCs (high-temperature fuel cells).

Products:

Alumina Ceramics; Ceramic Cutting Blade; Ceramic Filling Pump; High

Temperature Ceramics, Zirconia Ceramics

Ceramic Properties:

- High hardness

- Wear & abrasion resistant

- High compressive strength

- High mechanical Strength

- Resists strong acid and alkali attack at high temperatures

- Excellent electrical insulation properties

- High thermal conductivity

- Excellent refractory material

- Very specific thermal conductive and thermal expansion rates

- Low density

- Resistant to thermal shock

- High dielectric strength

- Transparent to microwave radio frequencies

Zirconia ceramic are used in shaft , plunger, sealing structure,

auto mobile Industrial, oil drilling equipment, Insulation parts in

electrical equipment , ceramic knife, ceramic hair clipper spare

parts, with high density, bending strength and breaking tenacity.

We can supply the products according to customer's drawings,

samples and performance requirement.

precison ceramic, precision ziconia ceramic, zirconia, ceramic

part, ceramic structure, zirconia ceramic shaft sleeve pipe roller

tube, zirconia ceramic shaft piston and gear, Zirconia ceramic rod,

machinable ceramic rod for industry

| Product Name | Insulating Precision Machinable Ceramic Block Machining Ceramic

Parts Drilling Hole |

| Material | zirconia or alumina ceramic |

| Color | White |

| Size | According to drawings |

| Surface Roughness | Ra 0.05 |

| Tolerance | +/-0.001 |

| Type | Full Ceramic, Ceramic+Steel |

| Lead time | 15 - 20days |

| Samples | Avaliable |

| Shipping | Air Express (DHL/UPS/TNT/ FedEx) or Ocean Shipping |

Properties of Alumina and Zirconia Ceramic :

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

Company Introduction:

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts . Our main products

include ceramic rod , ceramic tube, ceramic plunger, ceramic valve,

ceramic plate, ceramic shaft and bearing , ceramic nozzle etc ,

which are mainly used in industrial fields of Machinery,

Petrochemical oil and gas, Valves, Automotive, Food Processing,

Fluid Handling, Process Control, Thermal Processing, Aerospace,

Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great

successes in particular requirements

which is based on cooperating with Tsinghua University and getting

rich experience by our professional technical engineer teams . Our

factory have an unique technical called mirror polishing which

improve

our products more smooth , bright than other competitors.

Application Industry :

FAQ :

1. Are you a manufacturer ?

Yes we are a ceramic manufacturer . We proceed with the whole

process start from Powder material to forming , sintering ,

machining, marking , inspection , packing , we do the whole process

.

2. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic

parts .

3. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die

casting , tape casting , injection molding, etc, injection molding

and isostatic molding is the most commonly used.

4.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial

ceramic parts.

5.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to

the product complexity .

6.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but

paypal and western union only for small -sum payment.