Product Description:

The Custom Permanent Magnetic Assembly is a versatile and

high-performance magnetic solution designed to meet a wide range of

industrial and commercial applications. Engineered with precision

and tailored to specific requirements, this product offers

exceptional magnetic properties combined with durable construction,

ensuring reliable performance even in demanding environments.

One of the standout features of this magnetic assembly is its broad

operating temperature range, which spans from -40°C to 150°C,

depending on the type of magnet used. This makes it suitable for

applications in environments that experience extreme cold or

moderate heat. Additionally, the working temperature of this

product can range from 20 to 500 degrees Celsius, providing

excellent stability and magnetic strength under various thermal

conditions.

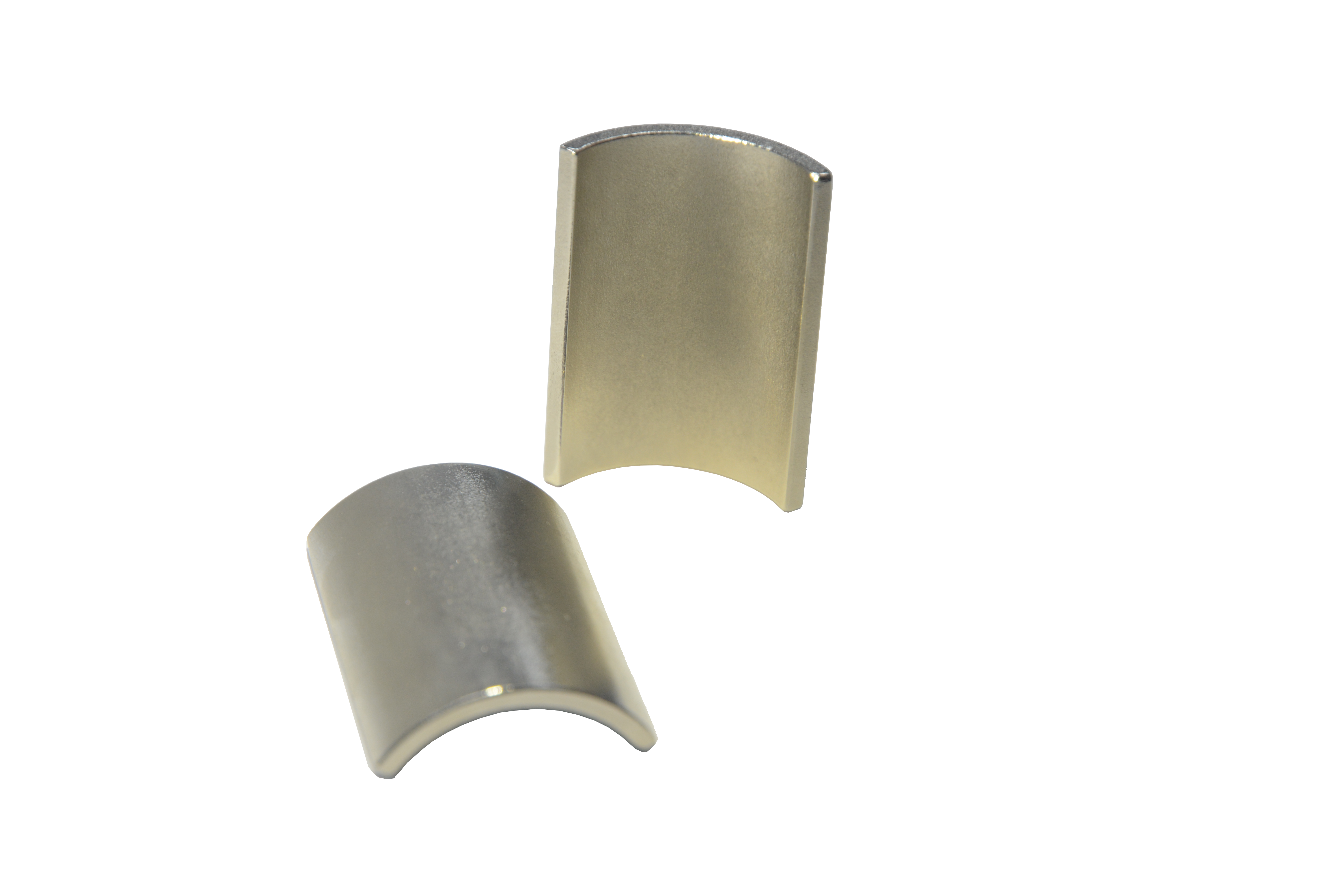

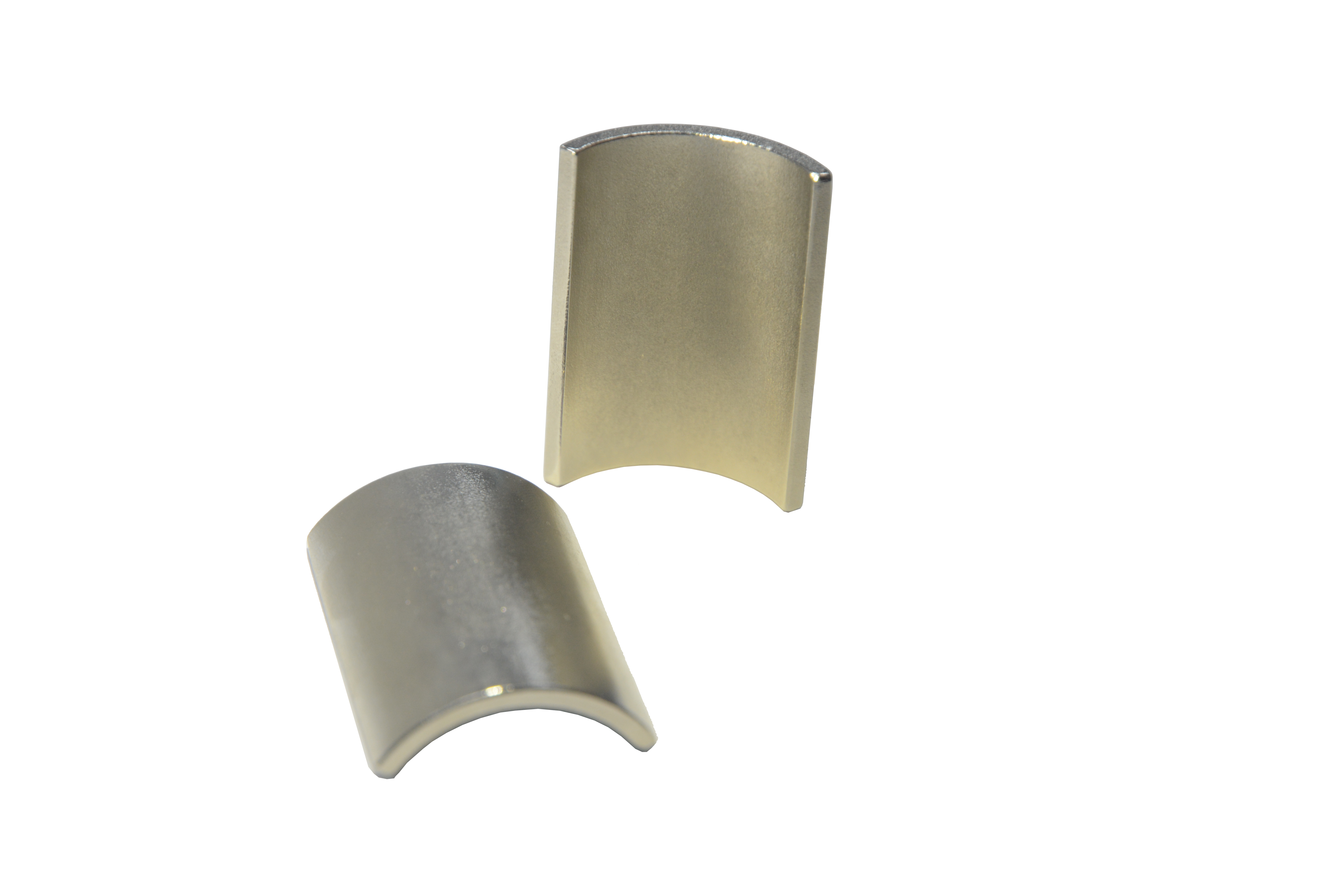

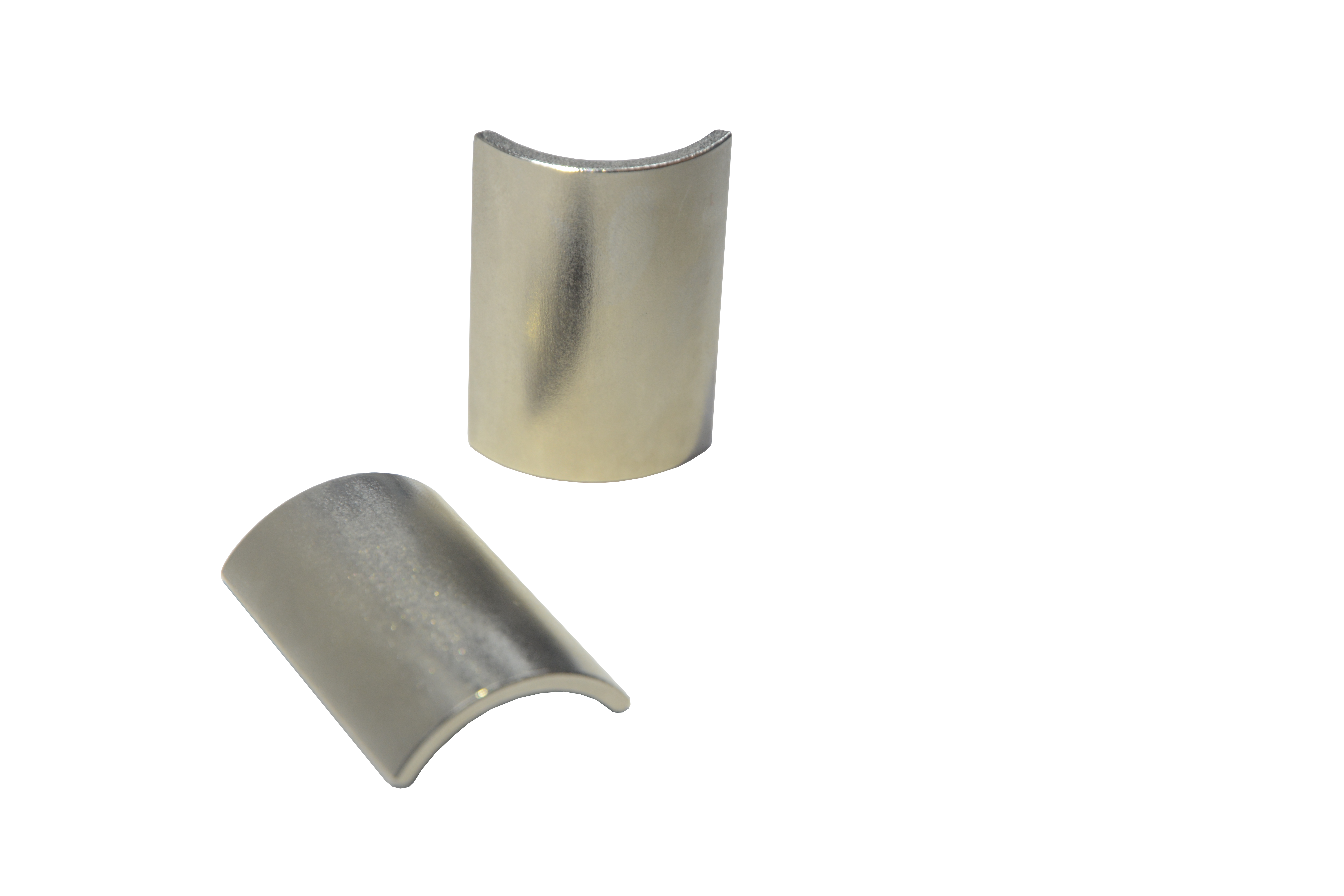

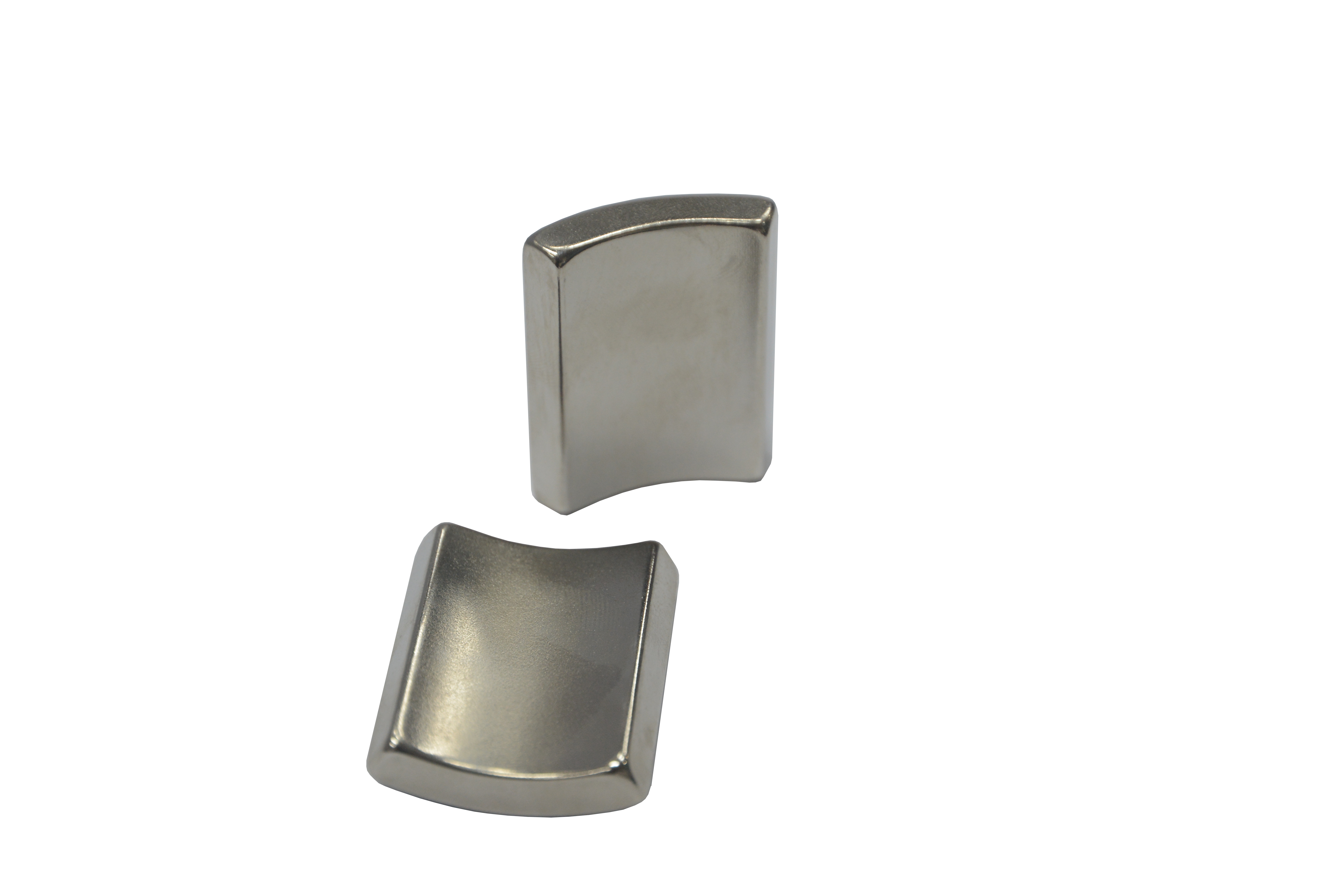

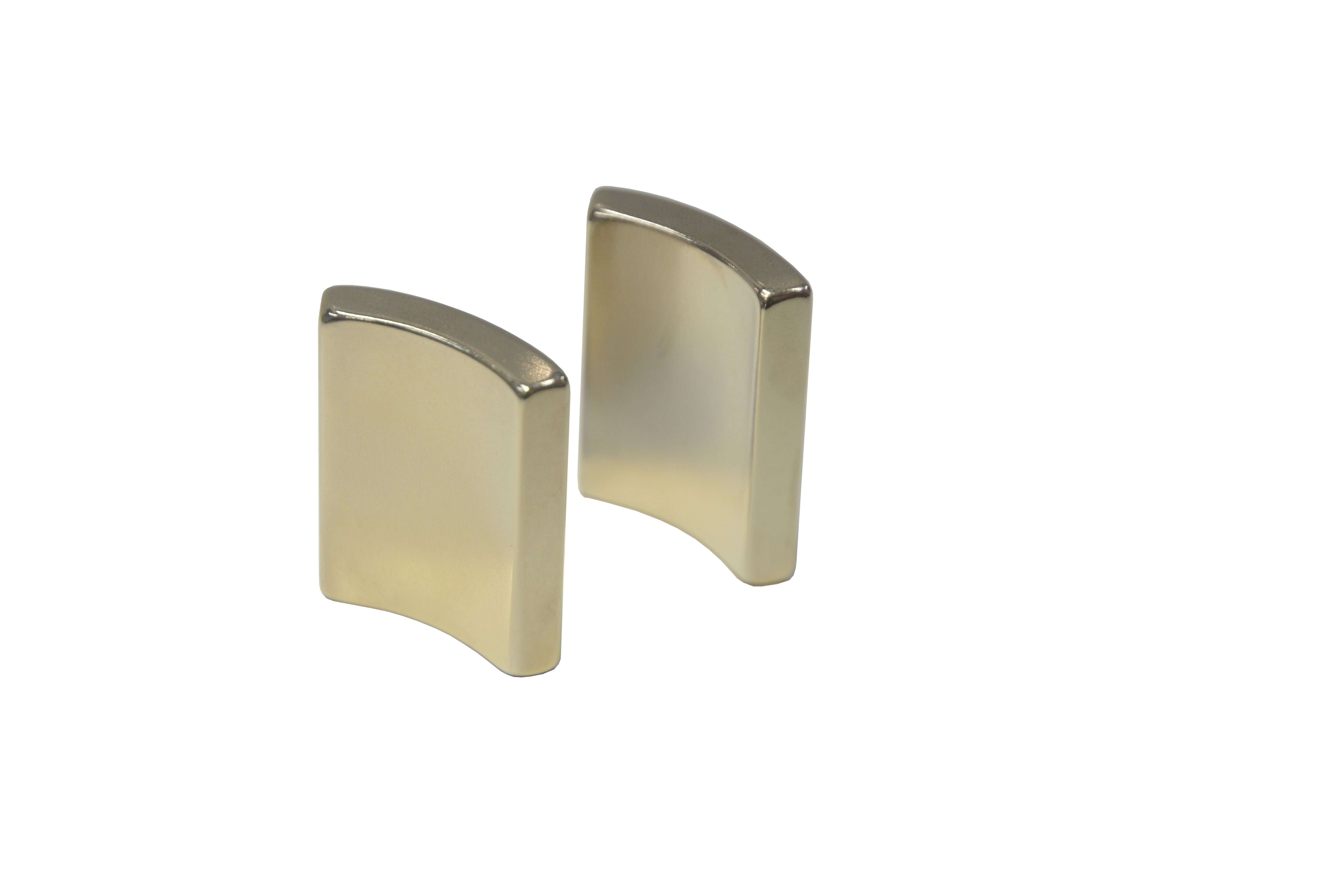

Customization is a key aspect of this magnetic assembly. Available

in multiple magnet shapes such as ring, block, disc, arc, cylinder,

and other custom shapes, it can be tailored to fit unique design

specifications. This versatility allows it to cater to different

industries including automotive, electronics, medical devices, and

industrial machinery, where specific shapes and sizes of magnets

are crucial for optimal performance.

The Custom Permanent Magnetic Assembly is predominantly black in

color, which not only gives it a sleek and professional appearance

but also helps in reducing glare and reflection in sensitive

applications.

Manufacturing and processing services for this product include

precise cutting techniques that ensure each magnet conforms to

exact dimensions and tolerances. This cutting service is essential

for creating complex shapes and sizes that meet the exact needs of

customers. Whether you require intricate custom shapes or standard

forms, the cutting process guarantees high accuracy and quality.

Alnico magnets are known for their excellent temperature stability

and resistance to demagnetization, making them ideal for

applications requiring consistent magnetic performance under

fluctuating thermal conditions. Their robustness and magnetic

strength make them a preferred choice in many engineering

applications.

Combining the benefits of traditional Alnico Permanent Magnets and

modern Injection Molded Magnets, the Custom Permanent Magnetic

Assembly delivers a high level of performance tailored to specific

operating conditions and design needs. Whether your application

demands high-temperature resistance, precise custom shapes, or

durable and reliable magnetic strength, this product is engineered

to deliver.

Features:

Product Name: Custom Permanent Magnetic Assembly

Color: Black

Assembly Material: Stainless Steel, Aluminum, Plastic, Custom

Materials

Magnet Shapes Available: Ring, Block, Disc, Arc, Cylinder, Custom

Shapes

Working Temperature Range: 20-500 Degree Celsius

Surface Treatment: Nickel Coating and other options

Includes Customized Magnets tailored to specific requirements

Compatible with Electro Permanent Magnetic Chuck systems

Utilizes Alnico Permanent Magnet technology for reliable

performance

Technical Parameters:

Type Permanent, Permanent

Grade SmCo Magnet, Y25, Y30, Y32, Y35 Etc

Packing Carton

Specifications Customize

Working Temperature 20-500 Degree Celcius

Magnet Coating Nickel-Copper-Nickel (Ni-Cu-Ni), Epoxy, Zinc, Gold,

Silver

Operating Temperature Range -40°C To 150°C (depending On Magnet

Type)

Color Black

Processing Service Cutting

Magnet Shape Ring, Block, Disc, Arc, Cylinder, Custom Shapes

Applications:

Custom Permanent Magnetic Assembly products are highly versatile

and designed to meet the specific needs of various industries.

These assemblies come in a variety of magnet shapes including ring,

block, disc, arc, cylinder, and other custom shapes, allowing for

tailored solutions that fit unique design requirements. With an

operating temperature range from -40°C to 150°C depending on the

magnet type, these magnets provide reliable performance in both

extreme cold and high heat environments.

The Custom Permanent Magnetic Assembly is widely used in

applications such as motors, sensors, magnetic couplings, magnetic

bearings, and medical devices. Sensors utilize these magnetic

assemblies for precise detection and measurement, improving

accuracy and responsiveness. Magnetic couplings benefit from the

strong and stable magnetic fields provided by these assemblies,

facilitating seamless torque transmission without physical contact.

Magnetic bearings rely on the high-grade SmCo magnets and grades

like Y25, Y30, Y32, and Y35 to support rotors with minimal

friction, increasing the lifespan and performance of rotating

machinery. In the medical field, these magnets are integral to

devices requiring precise magnetic properties and biocompatibility.

The availability of different grades such as SmCo magnet and

various grades including Y25, Y30, Y32, and Y35 ensures that the

magnetic assemblies can be customized to meet specific strength and

temperature requirements. Surface treatments like nickel coating

enhance corrosion resistance and durability, providing longer

service life in demanding environments.

Moreover, the incorporation of injection molded magnets in the

manufacturing process allows for the creation of complex shapes and

assemblies with tight tolerances and consistent magnetic

performance. This capability is crucial for producing customized

magnets that fit precisely into advanced technological

applications.

Customization:

Our Custom Permanent Magnetic Assembly services offer tailored

solutions to meet your specific needs. We provide various

magnetization directions including Axial, Radial, Diametrical, and

Multi-pole configurations to ensure optimal performance for your

application. The assembly materials can be customized from

Stainless Steel, Aluminum, Plastic, or any other custom materials

to suit your requirements.

Each assembly features a durable surface treatment such as Nickel

Coating to enhance corrosion resistance and longevity. The standard

color for these assemblies is black, providing a sleek and

professional appearance. Our products are designed to operate

efficiently within a temperature range of -40°C to 150°C, depending

on the magnet type used.

Support and Services:

Our Custom Permanent Magnetic Assembly product is backed by

comprehensive technical support and services to ensure optimal

performance and customer satisfaction.

Our experienced technical support team is available to provide

expert advice on product selection, customization options, and

troubleshooting. We help you integrate the magnetic assemblies into

your applications efficiently and effectively.

In addition, we provide custom design services to tailor magnetic

assemblies to your specific requirements, ensuring the perfect fit

for your unique application needs. Quality assurance and rigorous

testing protocols are in place to guarantee the reliability and

durability of each assembly.

We also offer repair and replacement services to minimize downtime

and maintain operational continuity. Our commitment to customer

service means you receive timely and responsive support at every

stage.

Packing and Shipping:

Each Custom Permanent Magnetic Assembly is carefully packaged to

ensure maximum protection during transit. The product is first

wrapped in anti-static and corrosion-resistant materials to prevent

any damage or degradation. It is then securely placed in a

custom-fitted foam or molded plastic insert inside a sturdy,

double-walled cardboard box to minimize movement and absorb shocks.

For larger or heavier assemblies, additional reinforcement such as

wooden crates or palletization may be used to provide extra

stability and safety. All packages are clearly labeled with

handling instructions, product details, and shipping information to

ensure proper care throughout the delivery process.

Shipping is handled through reliable carriers with tracking options

available, allowing customers to monitor their order status in real

time. We also offer expedited shipping services for urgent orders.

Our packaging and shipping protocols are designed to deliver your

Custom Permanent Magnetic Assembly promptly and in perfect

condition.

FAQ:

Q1: What materials are used in the Custom Permanent Magnetic

Assembly?

A1: Our Custom Permanent Magnetic Assemblies are typically made

from high-quality rare earth materials such as neodymium (NdFeB) or

samarium cobalt (SmCo), depending on your specific application

requirements.

Q2: Can the magnetic strength be customized for different

applications?

A2: Yes, the magnetic strength can be tailored to meet your needs

by adjusting the size, shape, and grade of the magnets used in the

assembly.

Q3: What shapes and sizes are available for these magnetic

assemblies?

A3: We offer a wide range of shapes and sizes, including rings,

blocks, discs, and custom geometries to fit your design

specifications.

Q4: Are these magnetic assemblies suitable for high-temperature

environments?

A4: Yes, depending on the material selected, such as samarium

cobalt, our magnetic assemblies can operate reliably at elevated

temperatures up to 350°C.

Q5: How precise are the tolerances for the custom magnetic

assemblies?

A5: We provide tight dimensional tolerances to ensure the

assemblies fit perfectly in your application, typically within

±0.05 mm, but this can be adjusted based on your requirements.