Product Description:

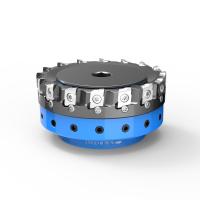

Face milling cutters are essential milling tools widely used in

various machining operations to achieve high precision and

excellent surface finishes. Designed for both face and shoulder

milling, these cutters are indispensable in manufacturing

environments where accuracy and efficiency are paramount. Whether

you are working with CNC milling machines or manual milling

machines, face milling cutters provide versatile and reliable

performance to meet diverse machining needs.

One of the key features of face milling cutters is their cutting

edge type, which can be either indexable or solid. Indexable face

milling cutters are equipped with replaceable milling inserts that

can be rotated or replaced when worn out, significantly reducing

downtime and tooling costs. These milling inserts come in various

shapes and grades, allowing for optimal cutting performance across

different materials and machining conditions. On the other hand,

solid face milling cutters are made from a single piece of

high-quality material, offering robustness and stability for

heavy-duty milling tasks. The choice between indexable and solid

cutting edge types depends on the specific application

requirements, material type, and desired surface finish.

Face milling cutters are designed with a helix angle ranging from

15° to 45°, which plays a crucial role in chip evacuation, cutting

forces, and surface finish quality. A lower helix angle, around

15°, is typically used for heavy roughing operations, providing

strong cutting edges and efficient material removal. Conversely, a

higher helix angle, up to 45°, is suitable for finishing operations

where smooth surface quality is critical. This adjustable range of

helix angles ensures that face milling cutters can be tailored to

meet the exact demands of various milling tasks, delivering both

productivity and precision.

Compatibility is another important aspect of face milling cutters.

These milling tools are designed to work seamlessly with both CNC

milling machines and manual milling machines, making them highly

versatile for different workshop setups. CNC milling machines

benefit from the precision and repeatability provided by face

milling cutters, enabling complex machining processes with minimal

operator intervention. Meanwhile, manual milling machines allow

machinists to perform detailed and controlled milling operations,

utilizing face milling cutters to achieve consistent results with

ease.

Face and shoulder milling are the primary applications of face

milling cutters. In face milling, the cutter removes material from

the surface of a workpiece to create a flat or contoured surface

with a high-quality finish. Shoulder milling involves cutting

vertical or near-vertical surfaces, often creating steps,

shoulders, or grooves on the workpiece. The design and geometry of

face milling cutters, along with the appropriate milling inserts,

allow for efficient and precise material removal in both

operations, enhancing the overall productivity and quality of the

machining process.

In summary, face milling cutters are versatile and high-performance

milling tools essential for modern machining operations. Their

indexable or solid cutting edge types, compatibility with various

milling machines, and adjustable helix angle from 15° to 45° make

them suitable for a wide range of applications, including face and

shoulder milling. By using quality face milling cutters and the

right milling inserts, manufacturers can achieve superior surface

finishes, reduce machining time, and extend tool life, ultimately

improving production efficiency and product quality.

Features:

- Product Name: Face Milling Cutters

- Application: Surface Milling, Face Milling

- Customized Support: OEM, ODM, OBM

- Cutting Speed: Up To 300 M/min

- Product Usage: Face And Shoulder Milling

- Compatible with various milling inserts for enhanced performance

- High-quality milling tools designed for precision and durability

- Efficient indexable milling cutters suitable for diverse milling

operations

Technical Parameters:

| Product Name | Face Milling Cutters |

| Weight | 0.5kg To 5kg |

| Processing Type | Finishing Or Roughing Machining |

| Coolant Type | Flood Coolant Or Dry Cutting |

| Cbn Content | 90~95% |

| Length | 50mm |

| Product Usage | Face And Shoulder Milling |

| Diameter | 25-32mm |

| Customized Support | OEM, ODM, OBM |

| Cutting Speed | Up To 300 M/min |

Applications:

Worldia's Face Milling Cutters, featuring the BEHW PCD Tipped

Milling Inserts, are designed for high-performance milling

applications in various industrial settings. These cutters are

ideal for both face and shoulder milling, providing precision and

efficiency in metalworking processes. With a CBN content of 90~95%,

these face milling cutters deliver exceptional hardness and wear

resistance, making them suitable for milling tough materials with

minimal tool wear.

These face milling cutters are widely used in manufacturing

environments where precision and surface finish are critical. They

are perfect for milling operations on steel, cast iron, and other

hard materials, ensuring smooth and accurate cuts. The cutters

support both flood coolant and dry cutting methods, providing

versatility and adaptability to different machining conditions and

ensuring optimal heat dissipation and tool life.

Packaging is done in sturdy Blue Boxes to ensure safe delivery, and

with a supply ability of 20,000 units, Worldia can meet both small

and large volume production demands. The minimum order quantity is

just 1, making these face milling cutters accessible for custom or

small batch orders. Delivery times range from 5 to 15 days,

allowing for prompt procurement and minimal downtime in production

schedules.

Worldia offers customized support with OEM, ODM, and OBM services,

enabling clients to tailor the mills to specific requirements and

applications. Whether for automotive, aerospace, or general

machining industries, these face milling cutters stand out due to

their precision, durability, and adaptability. They are essential

tools for any workshop or manufacturing facility looking to enhance

milling efficiency and achieve superior machining results.

In summary, Worldia's face milling cutters are versatile mills

engineered for demanding milling tasks. Their robust design and

high-performance inserts make them reliable tools for face and

shoulder milling, capable of handling diverse materials with

excellent cutting performance. These mills ensure consistent

quality, longer tool life, and cost-effective machining solutions

across various industrial applications.

Customization:

Worldia offers customizable Face Milling Cutters featuring the BEHW

PCD Tipped Milling Inserts, designed for both finishing and

roughing machining processes. With a minimum order quantity of just

1, these milling inserts are perfect for surface milling and face

milling applications, ensuring precision and efficiency.

Our products come securely packaged in blue boxes, guaranteeing

safe delivery within 5 to 15 days. With a supply ability of 20,000

units, we can meet varying demands for both CNC milling machines

and manual milling machines.

These versatile mills are ideal for face and shoulder milling

tasks, providing reliable performance across different machining

needs. Worldia supports full customization options including OEM,

ODM, and OBM services to tailor the milling inserts to your

specific requirements.