1. Company Overview

Enterprise History & Strength & Global Perspective

Company Identity and Positioning

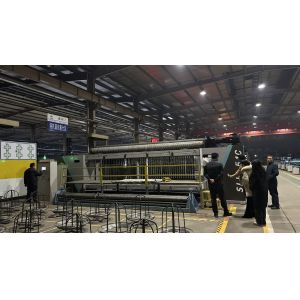

Anping Weaver Wire Mesh Equipment Manufacturing Co., Ltd. is based

in Anping, the Wire Mesh Capital of China, and specializes in the

development and manufacturing of CNC wire mesh machinery. With a

global vision, we deliver high-precision, intelligent, and

sustainable solutions to customers worldwide.

Industrial background and enterprise DNA

Anping boasts over 500 years of wire mesh heritage and is home to

the world’s largest wire mesh industrial cluster. Leveraging this

integrated ecosystem and strong governmental support, we ensure

agility and cost-efficiency in delivery.

Our company inherits over 40 years of expertise from the automotive

industry, operating under the IATF 16949 quality management system, bringing automotive-grade precision and reliability to wire mesh

machinery manufacturing.

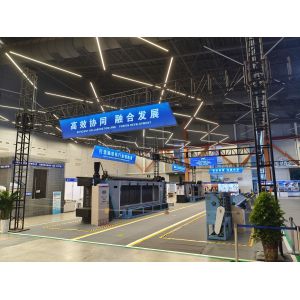

Internationalization positioning

Our products are exported to Europe, the Americas, Asia, and the Middle East, supported by remote technical assistance, operator training, and

efficient global delivery—empowering our clients to stay ahead in a

competitive market.

Cooperate philosophy

Action for excellence, integrity for trust, learning from Customers,Growing Together.

1.Company Mission

To deliver high-precision, intelligent wire mesh machinery

solutions for global customers, enabling efficient, safe, and

sustainable manufacturing.

2. Company Vision

Rooted in the Wire Mesh Capital, Weaving a Global Smart

Manufacturing Network

3. Core Values

· Execution with Excellence: Deliver on every commitment with precision and reliability.

· Integrity & Partnership: Build trust through honesty and transparency for long-term success.

· Co-Creation & Growth: Learn from our customers to innovate and improve, driving mutual

growth.

4.Quality Policy

We adhere to the IATF 16949 automotive industry quality management system, implementing full-process quality control and continuous

improvement to ensure every machine delivers precision, stability,

and reliability—providing trusted intelligent manufacturing

solutions worldwide.

5.Cultural DNA

Our culture is rooted in Practical Action, Integrity, and Continuous Learning. We believe that execution creates value, honesty builds trust,

and learning fuels innovation.

2.Why Choose Us

· 1️⃣Automotive-Grade Quality

Compliant with IATF 16949 standards for consistent reliability

· 2️⃣Patented 5-Axis CNC Technology

Ensuring superior weaving accuracy and stability

· 3️⃣ Full CNC Automation

Reducing labor dependency for consistent quality

· 4️⃣ Modular Design

Quick changeovers for multiple specifications

· 5️⃣Global Delivery & Support

Serving Europe, Asia, and Middle East with remote support

· 6️⃣ Customized Solutions

Tailored machine size & mesh specs to your needs

Optional

“Precision. Reliability. Innovation. This is our commitment to every

customer.”

3.Core Products

1.Metal Wire Mesh Weaving Machine:

Our independently developed Metal Wire Mesh Weaving

Machine is widely used in industrial applications such as

precision filtration mesh, protective mesh, and screening mesh. The

machine supports various wire diameters and mesh sizes and is

compatible with stainless steel, copper, nickel, aluminum, and

other metallic wires. Customers can flexibly configure key

components such as machine type, drive system, tension control, and

CNC system to achieve efficient and precise automated production.

Product Features

· Weaving widths from 1300mm to 2300mm to meet diverse production

needs

· Supports plain weave, twill weave, Dutch weave, and more

·High-precision tension and control systems suitable for fine wires

and dense mesh

· Self-developed system

· Customizable to meet specific technical or structural requirements

Note:

This is the specification table for our current basic models of

metal wire mesh weaving machines.

We can provide customized production based on the customer's

specific requirements.

On top of the basic models, flexible configuration options are

available to meet different production needs.

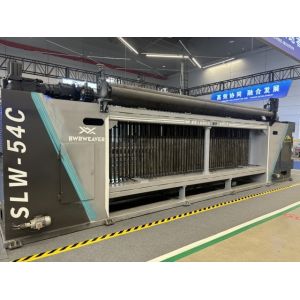

2.Gabion Mesh Machine :

- We specialize in the R&D and manufacturing of high-performance

gabion mesh machines, widely used in hydraulic engineering, slope

protection, infrastructure construction, and eco-restoration

projects. Featuring a

self-developed 5-axis CNC linkage system, our machines lead the

industry in weaving precision, operational stability, and

intelligent automation. Combined with full CNC automation, modular

design, and eco-friendly operation, we deliver

flexible, efficient, and sustainable gabion mesh solutions for

global clients.

- To meet diverse customer requirements in precision, efficiency, and

weaving complexity, we offer 3-axis and 5-axis

linkage drive CNC gabion mesh machines. We recommend

evaluating your specific production needs before selection.

Customized configuration services are also available. Please refer

to the comparison chart below for more details.

4.Technology & Solutions

· 先进技术(CNC控制,AI张力控制)Advanced technologies (CNC control, AI tension

control)

· 智能化+节能设计 Intelligentization + Energy-saving Design

· 远程诊断与数字化管理 Remote diagnosis and digital management

5. Application

· 防洪工程 | Flood Control

· 道路护坡 | Road Protection

· 工业过滤 | Industrial Filtration

· 景观工程 | Landscaping

6. Service Commitment

· 12个月质保(12-Month Warranty)

· 安装与培训(Installation & Training)

· 远程技术支持(Remote Technical Support)

· 本地化备件供应(Local Spare Parts Plan)

· 测试与检验(Inspection & Video Confirmation)

7. Contact

Anping Weaver Wire Mesh Equipment Manufacturing Co., Ltdt

Tel: +86 318-7738888 | Email:reidma1989@163.com

Url: www.apweaver.com