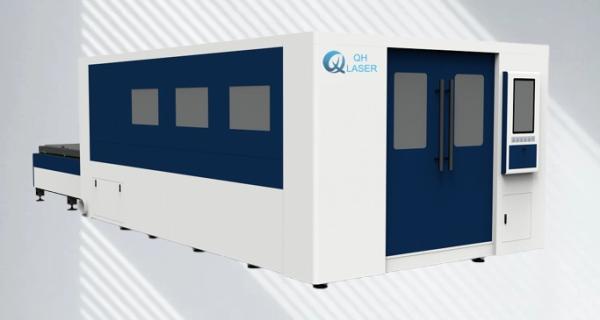

Qihai Laser Tech. Co., Ltd.

Founded in 2005, Qihai Laser Technology Industry Group Co., Ltd, a

high-tech enterprise specializing in the research, production,

sales and service of metal cutting equipment, has now dedicated to

providing metal cutting equipments and hardware machining

accessories to global customers, aiming to be the leader of laser

equipment manufacturer all over the world.

We have over 500 employees worldwide, serving over 30 countries and

regions. With an annual production capacity exceeding 10,000 units

of main laser equipment, we have achieved rapid growth over the

past 20 years.

As a strategic emerging industry supported by the state, Qihai

prioritizes product quality and reliability, earning recognition

from laser industry peers and customers. Qihai consistently

delivers exceptional quality and professional technical service to

our customers.