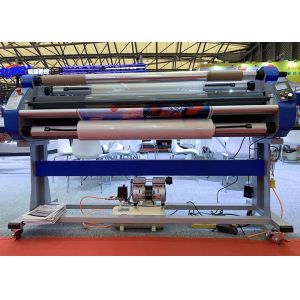

For professionals handling wide-format signage, vehicle wraps, and

high-value graphics, a standard machine simply won't cut it.

A true industrial Hot Roll Laminator needs features that solve

real-world production problems. Here is the ultimate 5-point

checklist defining the must-have capabilities for your next

laminator upgrade.

Must-Have: Precise Warm-Assist for Flawless Finishing.

Many pressure-sensitive (cold) laminators struggle with a common

defect: silvering (the hazy, reflective bubbles seen in dark print

areas). This is often an expensive quality failure—

Feature: Top Heated Roller (Max Temp: 60℃).

Why It Matters: The 60℃ Assist is a game-changer. It's not for traditional thermal

lamination; it’s a strategic temperature that gently warms the

adhesive on pressure-sensitive films. This slight increase in

temperature allows the adhesive to properly "wet out" into the

micro-valleys of digital inks and textured media, permanently

eliminating silvering without shrinking the material.

Buyer’s Checklist: Does the machine offer a precisely controlled, low-temperature top

heat feature for cold lamination assistance?

Must-Have: Uniform, Industrial-Grade Pressure Control.

In large-format lamination (Max Lam Width: 1630mm), maintaining

even pressure across the entire width is non-negotiable.

Manual crank systems often lead to pressure differences, resulting

in wrinkles or inconsistent adhesion.

Feature: Pneumatic Up and Down.

Why It Matters: Pneumatic Lift (air pressure-driven rollers) ensures the pressure

applied is perfectly uniform and repeatable across the entire

1630mm. This stability is critical for reliably running at high

speeds and for precision mounting. Furthermore, the pneumatic

system allows for quick, effortless opening and closing of the nip

gap, speeding up material changeovers.

Buyer’s Checklist: Does the machine use a pneumatic system for roller pressure to

guarantee consistency and reduce setup time?

Must-Have: Operator-Focused Dual Controls

When working with materials up to 1630mm wide, constantly jogging

the machine from end-to-end to manage feeding and take-up wastes

valuable time and labor.

Feature: Front and Rear Control Panel.

Why It Matters: True production efficiency means enabling one-person operation.

Dual Control Panels allow the operator managing the material at the

take-up end to instantly fine-tune speed (Max Speed:12m/min) or

reverse the machine without having to walk around. This reduces

labor demands and maximizes the uptime of your Wide Format

Laminator.

Buyer’s Checklist: Does the machine feature full control panels accessible from both

the feeding and take-up ends?

Must-Have: Integrated Finishing Capabilities

The lamination process doesn't end when the film is applied; it

ends when the product is trimmed and ready to ship. Moving heavy,

wide-format rolls from the laminator to a separate cutting table

creates an unnecessary bottleneck.

Feature: Trimmer Holder (2 Single and 1 Double central blades)

Why It Matters: High-quality industrial machines must integrate finishing. The

included, robust trimmer holder allows you to perform slitting and

trimming immediately after lamination. You can go from Roll to Roll

media to a finished, trimmed graphic in a single pass, drastically

cutting down labor time and simplifying your workflow.

Buyer’s Checklist: Can the laminator integrate slitting tools to eliminate the

secondary trimming step?

Must-Have: Application Versatility

A premium Large Format Laminator should be capable of more than

just roll-to-roll work; it must handle high-value mounting

projects.

Feature: Max Lam Thickness: 28mm

Why It Matters: A generous nip opening of 28mm means your machine is not limited

to flexible media. This capacity allows you to easily mount

graphics onto rigid substrates like foam board, Gator Board, or

dense signage material, expanding your service offering and

maximizing your return on investment (ROI).

Buyer’s Checklist: Does the machine provide enough thickness capacity to handle heavy

mounting onto popular signage materials?

Investing in the Future of Your Workflow, insisting on features

like the 60℃ Assist and Pneumatic Lift, you ensure your new machine

meets the demands of modern digital print finishing. This isn't

about luxury; it’s about choosing a Smart System that delivers

quality, speed, and profitability.