For over 13 years Xinhaisen has pioneered developments in

photochemical etching, achieving standards admired by the industry

and appreciated by a global customer base from a wide range of

high-tech engineering markets.

Since found in 2012, in affiliating with our customers we have

pioneered many new production techniques and methodologies in order

to better serve their needs. It is these techniques that have

advanced our capabilities further, enabling us to take what was

once considered art and turn it into a science.

Now, we became China's leading photochemical etching specialist,

with also the capacity of offering stamping and laser-cutting

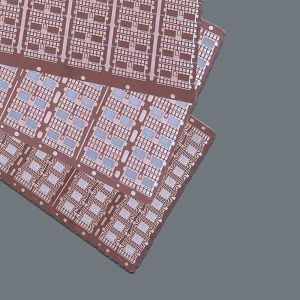

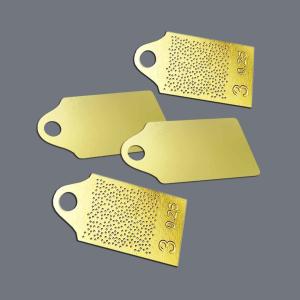

service. Our products include etching bipolar plates for fuel cell,

speaker grills, micro meshes&filters, tea&coffee

infusers, shims&gaskets, Optical encoderdisk&strip, EMI/RFI

shielding, Leadframes, connectors&contacts,

printingstencils&foils and metal crafts.

Quality and service is our mission, Xinhaisen is committed to

pursuing the highest standards of environmental performance.

Responsibility for sustainability resides with all employees. The

company has achieved ISO 14001 and IS0 9001 and IATF 16949 and is

committed to maintaining that standard. With a fast response, high

quality, best service and fair price, we have gained high

reputation from our customers all over the world.