High-Precision Copper Chemical Etching for Ultra-Thin & Complex

Metal Parts

What is Copper Etching?

| Copper etching (also known as chemical etching) is a process that

uses chemical etching to precisely remove metal from the copper

surface. It enables extremely high-precision dimensional control,

with tolerances as low as ±0.01mm. It is particularly suitable for

processing ultra-thin metal sheets, with thicknesses as low as

0.02mm. This high-precision processing technology has made copper

etching widely used in the manufacture of electronics,

micro-machinery, and high-precision components, while maintaining

product flatness and fine edge detail. |

|

Copper Etching Product Parameters

| Parameter Description |

| Material Type: | Copper (pure copper, copper alloy) |

| Minimum Thickness: | 0.02mm |

| Maximum Thickness: | 2.0mm |

| Dimensional Tolerance: | ±0.01mm |

| Minimum Aperture: | 0.1mm |

| Maximum Sheet Size: | 1800mm x 600mm |

| Etching Method: | Half Etching / Full Etching / Double-Sided Etching |

| Surface Treatment: | Nickel Plating, Sandblasting, Polishing, Protective Film |

| Production Options: | Single Sheet / Continuous Coil Production |

| Applicable Industries: | Electronics, Communications, Automotive, Medical Devices |

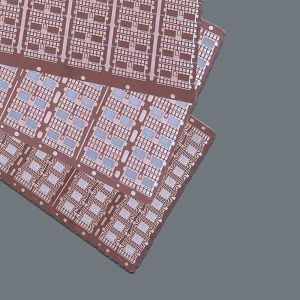

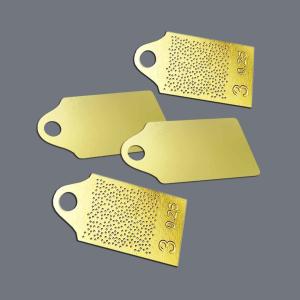

Applications and Products

| Copper etching is widely used in the production of high-precision

components such as microelectronic components, precision conductive

parts, sensors, heat sinks, speaker grilles, and micro springs. It

also has important applications in automotive electronics, medical

devices, aerospace, and communications equipment, providing

customers with high-precision, lightweight, and complex metal

components. |

Etching Methods and Production Capacity

Copper etching can be performed in half, full, or double-sided

etching modes to meet diverse process requirements. The company

also offers continuous etching of metal coils, ensuring stable and

efficient mass production and providing reliable support for

large-scale orders. |

Flexible Production and One-Stop Service

We support both mass production and small-batch customization,

offering rapid response and a one-stop precision metal solution.

From material sourcing and process design to finished product

inspection, we ensure that every copper etching product meets our

customers' stringent requirements, achieving a perfect combination

of high quality and efficiency. |

FAQ:

1.What is the price of vapor chamber customization?

-- The price will be depended on material, thickness, size and

other requirements, please feel free to send us your detail

requirements, we’ll offer you the price asap.

2. How do we custom the titanium vapor chamber?

-- Please send us your drawing in DXF, DWG, STEP, PDF and other

formats, we’ll do the evaluation and offer you the price.

3. How can we guarantee quality?

-- We always a pre-production sample before mass production, and always 100% final Inspection before shipment.

4. Why should you buy from us not from other suppliers?

-- Xinhaisen is established to specialized in the production of

high-quality, finite and micro-size photo chemical etching metal

products.Our seventy professional

staff specialized in research and development , manufacturing and

marketing service.

5. What services can we provide?

-- Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency:USD, EUR, JPY, CAD, AUD, HKD, CNY;

Accepted Payment Type: T/T, Paypal, Western Union, Cash.

Do you want to custom the vapor chamber?

Click "contact us" below to send us the drawing of Titanium vapor

chamber, we support DXF, DWG, STP etc. formats.