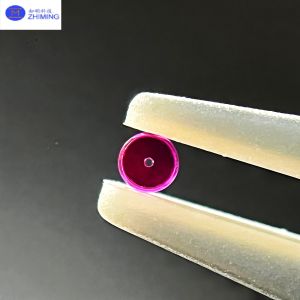

Product Overview

Through-hole ruby bearings are precision-engineered components made

from synthetic single-crystal ruby (Al₂O₃ doped with Cr₂O₃). These

bearings are designed with a central through-hole structure that

allows shafts, pins, or optical fibers to pass through smoothly

while minimizing friction and wear. Owing to ruby’s extreme

hardness (Mohs 9), outstanding chemical stability, and excellent

surface finish, these bearings are widely used in precision

instruments, metering devices, fiber optic assemblies, and

micro-mechanical systems where stability and long lifespan are

critical.

Material and Structure

The bearing body is made of synthetic corundum crystal, grown under

controlled conditions to ensure uniform hardness and purity.

Chromium doping gives the material its characteristic red color and

adds optical clarity and corrosion resistance. The through-hole is

precisely machined and polished to achieve micron-level dimensional

accuracy and smoothness, ensuring excellent coaxiality and low

friction in rotary or oscillating movement.

Typical Parameters

Material: Synthetic Ruby (Al₂O₃ + Cr₂O₃)

Hardness: Mohs 9

Density: 3.98 g/cm³

Operating Temperature: -60°C to +500°C

Hole Diameter: 0.05–5.0 mm (customizable)

Outer Diameter: 0.5–10 mm (customizable)

Concentricity Tolerance: ≤ 0.003 mm

Surface Roughness: Ra ≤ 0.02 μm

Key Features

Ultra-High Hardness & Wear Resistance – Ruby’s exceptional hardness ensures minimal abrasion,

maintaining stable dimensions over years of operation.

Smooth and Precise Rotation – The through-hole design and optical-level surface polish

guarantee low friction and high rotational accuracy.

Chemical & Thermal Stability – Ruby bearings can withstand acids, alkalis, solvents, and high

temperatures without deformation or corrosion.

Excellent Dimensional Precision – Each bearing is precisely lapped and inspected to meet strict

concentricity and parallelism standards.

Long Service Life – Even in high-speed or continuous-contact applications, ruby

bearings maintain performance and do not require lubrication.

Applications

Precision Measuring Instruments: Used in dial indicators, micrometers, and flow meters for stable,

friction-free movement.

Fiber Optic and Laser Systems: Serves as alignment and support components in optical connectors

and light transmission assemblies.

Watchmaking and Micro Motors: Provides low-friction pivoting for high-precision miniature

shafts.

Medical and Analytical Equipment: Ensures accurate motion in miniature pumps and sensor mechanisms.

Aerospace and Defense Devices: Ideal for compact, durable, and vibration-resistant bearing

solutions.

Advantages Over Metal Bearings

Quality and Customization

Each through-hole ruby bearing is subject to 100% inspection for

dimensions, hole alignment, and surface finish. Custom designs are

available for diameter, thickness, and hole geometry to meet unique

application needs. Assemblies combining ruby bearings with

stainless steel or ceramic housings can also be provided upon

request.

FAQ

Q1: What is the difference between a through-hole ruby bearing and

a cup ruby bearing?

A: A through-hole ruby bearing has an open bore running through it,

allowing a shaft or pin to rotate or slide freely. A cup ruby

bearing has a concave seat for point-contact rotation, typically

used in jewel pivots and instruments.

Q2: Can through-hole ruby bearings operate without lubrication?

A: Yes. Due to ruby’s ultra-smooth surface and hardness, these

bearings can work dry without oil or grease, even in vacuum or

cleanroom conditions.

Q3: Are these bearings suitable for high-speed rotation?

A: Yes, within design limits. Ruby’s high hardness and low friction

make it ideal for precision rotation, though speed tolerance

depends on shaft quality and assembly conditions.

Q4: Can I order custom hole sizes or special shapes?

A: Absolutely. We offer tailor-made ruby bearings with customized

hole diameters, countersinks, chamfers, and mounting styles based

on your drawings or samples.

Q5: How do you ensure consistency in optical and mechanical

performance?

A: All ruby materials are grown under strict crystal growth

control, and each part is processed using CNC micro-machining and

double-side polishing to guarantee uniformity.