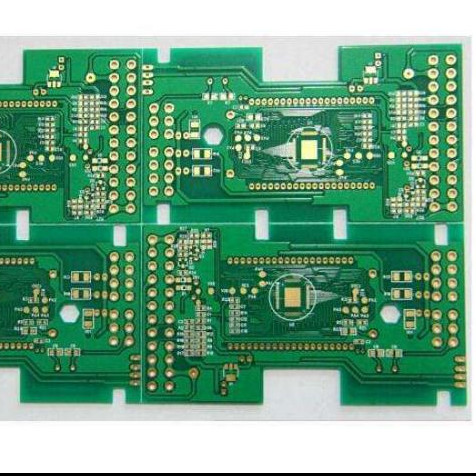

Dongguan Xingqiang Circuit Board Technology Co., Ltd.

Dongguan Xingqiang Circuit Board Co., Ltd. was established in 1995 and is a professional circuit

boardfactory that manufactures single-sided and

double-sided PCBs, multi-layer PCBs, and Rigid Flex PCBs.

The company has two production bases in Dongguan andJiangxi,

covering an area of 205000 square meters with a comprehensive

monthly production capacity of 200000 square meters. The

company's products are widely used in computer peripherals,

communication, power supply, medical, automotive electronics,

household appliances and other fields.

Our company advocate integrity, win-win and pioneering business

philosophy, and put into practice the work style of "pragmatism,

hard work and responsibility" to create a good corporate

environment. Based on a new management model, advanced technology

and equipment and good product quality, We always adhere to the

corporate spirit of customer first and people-oriented.