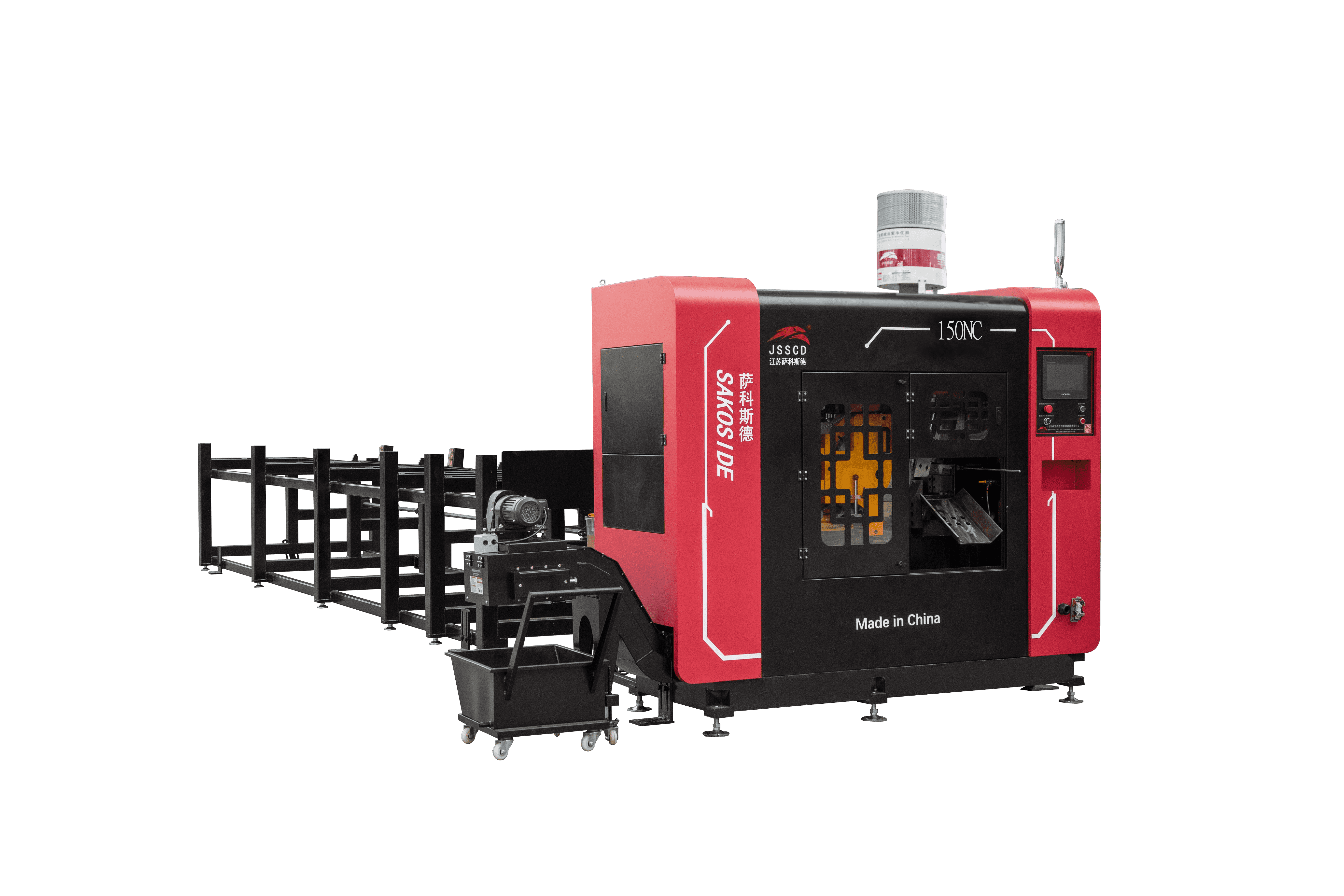

JSSCD-200NC/P CNC High Speed Circular Saw Machine(Horizontal-Push)

Description

Designed for high-output manufacturing, this horizontal CNC

circular saw provides fast, high-accuracy cutting for metal

profiles. Its blend of intelligent automation, robust engineering,

and precision build makes it a crucial resource in contemporary

metal fabrication, valued for dependable operation.

Versatile Fixturing & Cut Consistency

The system handles diverse sections—round tubes, angle iron, square

stock—using its multi-axis hydraulic clamping

(horizontal/vertical). This adaptable workholding minimizes

changeover time, boosting flexibility across varying material sizes

and forms. An advanced horizontal cutting action, powered by an AC

servo motor and ball screw drive, delivers essential stability. The

high-strength build and precise engineering of the drive and

clamping mechanisms firmly secure workpieces during fast operation.

This prevents vibration and ensures repeatable cut precision,

making it essential for continuous, high-volume production where

steadiness is critical.

Intuitive Control & Automated Workflow

At the core is an advanced CNC control module, acting as the

operational intelligence center. It allows fine-tuning of vital

parameters—cutting speed, angle—for efficient, exact results

meeting tight tolerances. A user-friendly HMI interface simplifies

programming. Cutting sequences are easily inputted, and multiple

job configurations stored, facilitating fully automated processing.

This greatly cuts manual involvement and error potential.

Optimized Automation & Durable Construction

An optional high-capacity automatic feeder enables continuous

material flow. Combined with the horizontal cutting method, it

permits smooth batch processing, maximizing equipment use and

output for large-scale, rapid runs. Long-term accuracy is preserved

by a precision-sustaining compensator (AC servo motor + ball

screw). A heavy-duty hydraulic system (stable pressure, large

reservoir) powers clamping and specific drives. Component longevity

is enhanced via a self-lubrication system (timed, metered oil) and

a tool micro-lubrication unit (air-powered cyclic, near-dry

intermittent oiling). Workspace tidiness and equipment safeguarding

are provided by a blade chip extraction device (hollow external

rotating magnetic brake), boosting operational safety. Clean part

separation is achieved by a material divider (carbide parallel

blocks).

Elevating Modern Metal Processing Efficiency

This High-Speed Horizontal Circular Saw effectively balances

rigorous precision needs with high-volume continuous throughput. It

stands as the leading solution for businesses aiming to boost

productivity, achieve superior part quality, and lower operational

costs. Utilizing smart control, rapid horizontal cutting

technology, and optional automation, the unit enhances material

usage, reduces scrap, shortens cycle times, and lessens labor

reliance. For metal processors focused on increasing

competitiveness and advancing towards smart manufacturing, this

efficient, robust, and intelligent horizontal saw is the definitive

choice for modern facilities, driving sustainable growth and

operational excellence.

Specifications:

| Model | Unit | JSSCD-200NC/P |

| Mainframe dimensions | mm | 2240*1790*1800 |

| Bar & round pipe | mm | 50-200 |

| Angle bar & square bar | mm | 50-180 |

| Saw blade size | mm | φ520*3.0*φ50 |

| Pin holes and hole diameters | mm | 4*φ16*80φ50 |

| Spindle motor power | KW | 22(6P) |

| Spindle speed | rpm | 30-80 |

| Feed servo motor power | KW | 2.8 |

| Feeding servo motor power | KW | 2.8 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 3.75 |

| Rated pressure of the hydraulic system | mpa | 3.75 |

| Hydraulic oil capacity | L | 110 |

| Cut off feed mode |

| AC servo motor & ball screw / horizontal entry |

| Main clamping method |

| Hydraulic type / one set each for horizontal and 15° |

| Saw blade debris removal device |

| Passive/active circular wire brush (optional) |

| Gear backlash compensation device |

| Hollow external rotating magnetic powder brake |

| Feeding drive mode |

| AC servo motor & ball screw |

| Feeding clamp method |

| Hydraulic type/Horizontal clamping |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system |

| Timed and quantitative forced oil supply |

| Micro-lubrication system for cutting |

| Quasi-dry intermittent oil supply |

| Material separating device |

| Pneumatic reciprocating |

| Long material receiving device |

| Optional |

| Blade swing anti-vibration device |

| Tungsten carbide parallel block |

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a

30,000 square meter factory and a team of dedicated technicians

specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our

city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a

test cut using our machine. After the test is complete, we will

provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for

your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of

your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.