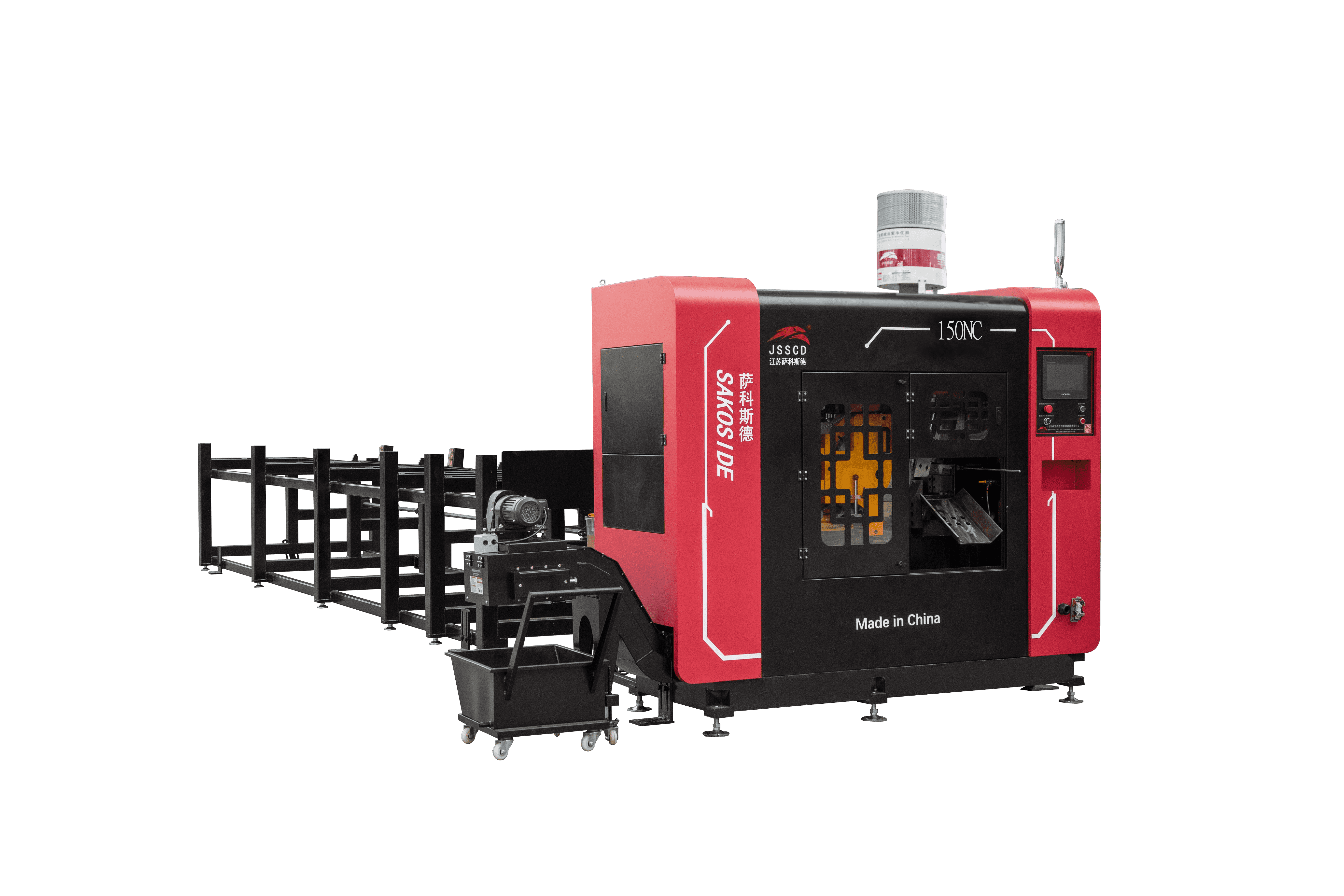

JSSCD-150NC/P CNC High Speed Circular Saw Machine(Horizontal-Push)

Description

Meeting the exacting standards of contemporary metal fabrication

demands cutting solutions that deliver both speed and pinpoint

accuracy, particularly for horizontal applications. This

high-performance CNC horizontal circular saw rises to this

challenge. It masterfully integrates swift cutting capability,

automated precision, and energy-conscious operation, positioning

itself as a fundamental component for dependable and efficient

metal processing.

Engineered for cleanly cutting diverse shapes—such as round and

square tubing, along with angle iron—its effectiveness stems from

key technological advances. The foundation lies in its

sophisticated horizontal insertion cutting mechanism, driven by an

AC Servo Motor paired with a precision ball-screw transmission.

This core technology guarantees remarkable operational smoothness

and absolute control during every cut cycle. Supporting this is an

enhanced hydraulic material fixation system (utilizing

horizontal/vertical clamping). This unified clamping strategy

significantly reduces fixture changeovers, greatly increasing the

machine's versatility for materials of different dimensions and

shapes. As a result, it capably processes a broad spectrum of

cutting tasks. The robust construction, featuring high-strength

materials and meticulously designed drive and clamping elements,

ensures unwavering workpiece security even at maximum operational

speeds, preventing any material creep. This bedrock guarantees

uniform cutting precision and excellent repeatability, making the

unit perfectly suited for non-stop production where speed and

steadiness are critical.

Consistent accuracy over prolonged operation is a defining feature.

A vital element is the integrated gear play elimination system

(also employing AC Servo Motor and ball-screw technology), which

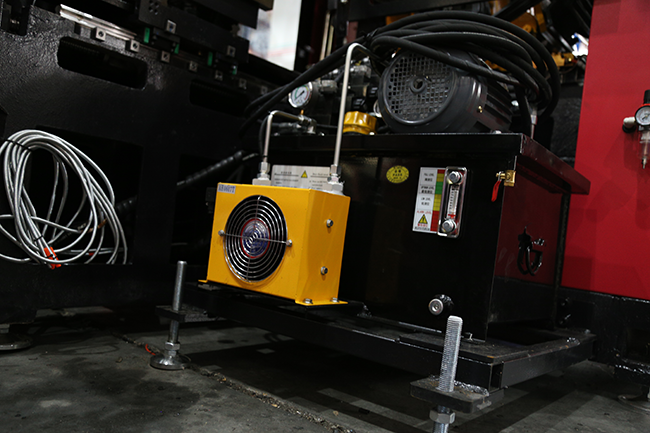

dynamically preserves precision during extended use. A robust

hydraulic system provides steady, rated pressure and ample oil flow

for clamping and auxiliary functions. Combined lubrication

approaches—a self-lubricating unit for timed, metered oil delivery

and a tool micro-lubrication system using air-actuated

reciprocation for near-dry, intermittent application—work to

drastically reduce wear on essential parts. This effectively

extends the equipment's operational lifespan and ensures sustained,

reliable performance. An integrated swarf removal system (featuring

a magnetic particle brake) efficiently clears cuttings, preserving

a tidy workspace, improving safety, and easing upkeep.

Additionally, a part separation device with carbide parallel guides

ensures orderly discharge of workpieces post-cut.

An advanced CNC control unit powers the machine's intelligence.

This system precisely manages crucial variables including feed rate

and cutting angle, ensuring consistently efficient and accurate

outcomes that meet rigorous quality requirements. The

high-precision CNC, coupled with an intuitive Human-Machine

Interface (HMI), offers straightforward operation. Setup is

simplified, and operators can easily store numerous machining

programs via the clear interface, achieving substantial automation.

This markedly reduces operator effort and effectively minimizes the

chance of human error.

For operations targeting peak output, an optional high-capacity

automated material handling system enables continuous, unmanned

feeding. This integrates seamlessly with the horizontal cutting

process to facilitate uninterrupted batch production. This

combination optimizes equipment utilization and overall line

throughput, ideally matching the needs of high-volume,

rapid-turnaround manufacturing.

Specification

| Model | Unit | JSSCD-150NC/P |

| Mainframe dimensions | mm | 2240*2320*2040 |

| Bar & round pipe | mm | 30-150 |

| Angle bar & square bar | mm | 30-138 |

| Saw blade size | mm | φ460*2.7*φ50 |

| Pin holes and hole diameters | mm | 4*φ16*80 φ50 |

| Spindle motor power | KW | 18.5/15 |

| Spindle speed | rpm | 20-110 |

| Feed servo motor power | KW | 2.3 |

| Feeding servo motor power | KW | 2.7 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 3.75(4p) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 110 |

| Cut off feed mode |

| AC servo motor & ball screw / horizontal entry |

| Main clamping method |

| Hydraulic type / one set each for horizontal and 15° |

| Saw blade debris removal device |

| Passive/active circular wire brush (optional) |

| Gear backlash compensation device |

| Hollow external rotating magnetic powder brake |

| Feeding drive mode |

| AC servo motor & ball screw |

| Feeding clamp method |

| Hydraulic type/Horizontal clamping |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system |

| Timed and quantitative forced oil supply |

| Micro-lubrication system for cutting tools |

| Quasi-dry intermittent oil supply |

| Material separating device |

| Pneumatic reciprocating |

| Blade swing anti-vibration device |

| Tungsten carbide parallel block |

In summary, this robust horizontal circular saw capably handles the rigors of

extensive continuous production while adhering to strict precision

demands. It represents an outstanding solution for businesses

focused on elevating efficiency, improving product consistency, and

reducing per-part costs. By leveraging smart control, advanced

horizontal insertion cutting, and adaptable automation, the machine

substantially improves material utilization, decreases waste,

shortens production cycles, and lessens reliance on manual labor.

For metalworking enterprises seeking enhanced competitiveness and

progression towards intelligent manufacturing, this durable,

reliable, high-output, and intelligent horizontal circular saw is

the definitive modern workshop asset, delivering powerful momentum

for sustainable growth and operational excellence.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a

30,000 square meter factory and a team of dedicated technicians

specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our

city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a

test cut using our machine. After the test is complete, we will

provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for

your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of

your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.