JSSCD-80NC/P CNC High Speed Circular Saw Machine(Horizontal-Push)

Description

Modern metal fabrication demands solutions that reconcile intensive

output requirements with stringent dimensional accuracy. This

CNC-controlled high-speed horizontal circular saw addresses this

critical challenge head-on. It integrates rapid cutting

performance, advanced control systems, unwavering precision, and

sustainable operation, establishing itself as essential

infrastructure for robust, consistent industrial metal processing.

Foundations of Engineering Integrity

The machine's defining achievement is its sustained dimensional fidelity across prolonged production runs. This capability is engineered through several interconnected

systems:

Precision Horizontal Cutting Mechanics: An AC servo motor, coupled with ball screw drive technology,

delivers exceptionally smooth and controllable feed motion.

Optimized Workpiece Securement: A multi-axis hydraulic clamping fixture ensures absolute material

immobilization. Engineered with resilient, precision components, it

prevents slippage even during the most demanding cuts, guaranteeing

repeatable accuracy. This design also facilitates swift adjustments

for diverse material sizes or geometries, minimizing downtime and

enhancing flexibility.

Enduring Accuracy Systems: Backlash is meticulously minimized within the servo/ball screw

drive train. Consistent clamping and feed pressure are maintained

by a potent hydraulic system. Component longevity is significantly

extended via an integrated lubrication approach: a smart, timed

central system combined with a pneumatic Minimal Quantity

Lubrication (MQL) unit for blade cooling drastically reduces wear,

allowing longer intervals between maintenance. Workspace

cleanliness and safety are improved by a magnetic chip evacuation

system employing a hollow rotary brake. Clean part separation

post-cut is ensured by a tungsten-carbide ejector.

Intuitive Control for Streamlined Operation

At the heart of the machine lies a dedicated PRECISION CNC CONTROL SYSTEM. This sophisticated unit precisely governs critical parameters

such as cutting speed and angular positioning, ensuring efficient

and accurate results for every component. Operation is simplified

through an intuitive Human-Machine Interface (HMI). Production

staff can effortlessly input specifications and store numerous

cutting programs via a user-friendly console, achieving a high

level of automation. This significantly lowers operator effort and

mitigates risks associated with manual setting errors.

Specifications:

| Model | Unit | JSSCD-80NC/P |

| Mainframe dimensions | mm | 2250*1790*1760 |

| Bar & round pipe | mm | 15-80 |

| Angle bar & square bar | mm | 15-68 |

| Saw blade size | mm | φ300*2.0*φ32 |

| Pin holes and hole diameters | mm | 4*φ11*63 φ32 |

| Spindle motor power | KW | 7.5(4P) |

| Spindle speed | rpm | 20-168 |

| Feed servo motor power | KW | 1.5 |

| Feeding servo motor power | KW | 1.5 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 6-860 |

| Hydraulic drive motor power | KW | 1.5(4P) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 70 |

| Cut off feed mode |

| AC servo motor & ball screw / horizontal entry |

| Main clamping method |

| Hydraulic type / one set each for horizontal and 15° |

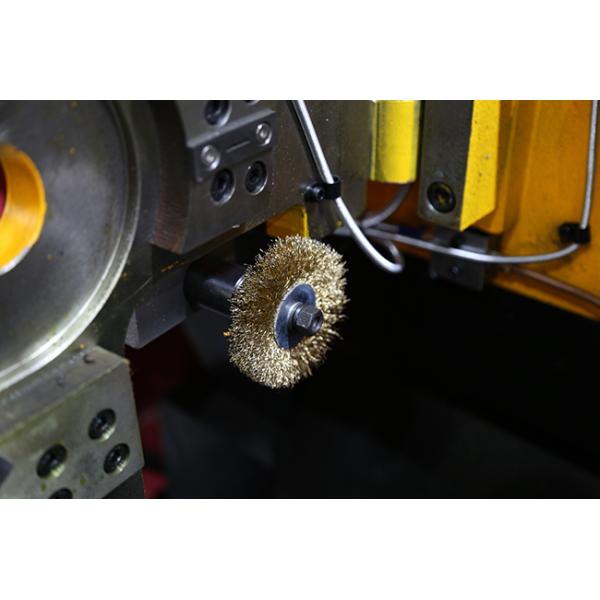

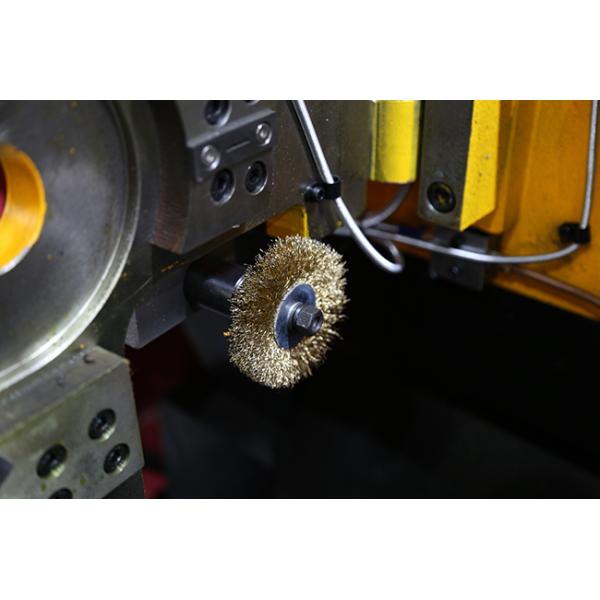

| Saw blade debris removal device |

| Passive/active circular wire brush (optional) |

| Gear backlash compensation device |

| Hollow external rotating magnetic powder brake |

| Feeding drive mode |

| AC servo motor & ball screw |

| Feeding clamp method |

| Hydraulic type/Horizontal clamping |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system |

| Timed and quantitative forced oil supply |

| Micro-lubrication system for cutting |

| Quasi-dry intermittent oil supply |

| Material separating device |

| Pneumatic reciprocating |

| Long material receiving device |

| Optional |

| Blade swing anti-vibration device |

| Tungsten carbide parallel block |

Elevating Throughput with Intelligent Automation

Operations focused on maximizing production volume can integrate an optional HIGH-CAPACITY AUTOMATED FEEDING SYSTEM. This seamlessly interfaces with the saw, providing continuous,

automated material supply perfectly synchronized with its

horizontal cutting stroke. It unlocks the potential for extended,

unattended batch processing, dramatically increasing equipment

utilization and overall line throughput to satisfy demanding

large-scale production schedules.

The Advantage for Progressive Metal Processing

This high-capacity horizontal circular saw directly confronts the

dual imperatives of serial production volume and exacting precision

cutting standards. It constitutes an optimal investment for

enterprises aiming to boost output rates, elevate component

quality, and curtail operational costs. By converging intelligent

CNC technology, sophisticated horizontal cutting dynamics, and

flexible automation, the system enhances material utilization,

reduces waste generation, shortens cycle durations, and decreases

dependence on manual tasks. For metalworking firms committed to

securing a competitive advantage and progressing towards

intelligent manufacturing, this reliable, high-efficiency, smart

horizontal circular saw forms fundamental equipment for the

contemporary facility, enabling superior operational performance

and sustainable advancement.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a

30,000 square meter factory and a team of dedicated technicians

specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our

city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a

test cut using our machine. After the test is complete, we will

provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for

your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of

your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.