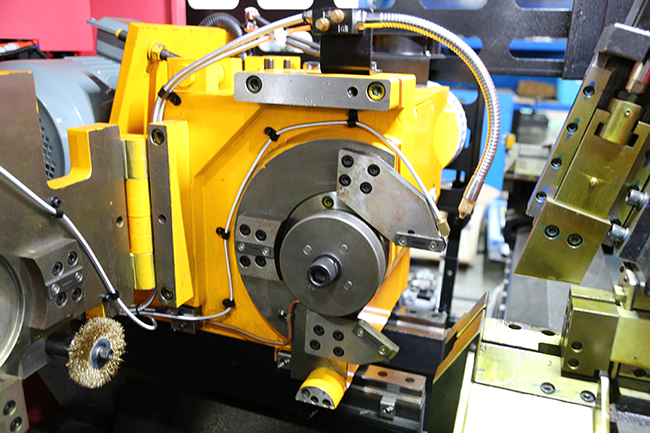

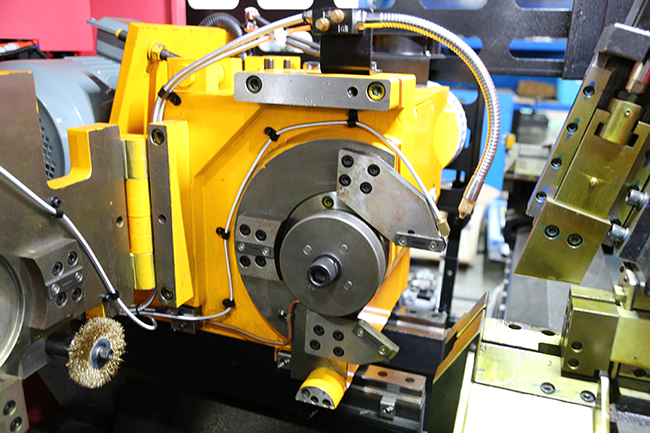

JSSCD-120NC/X CNC High Speed Circular Saw Machine(Angled-Push)

Description

In the metalworking industry where efficiency and precision are

paramount, this professionally designed CNC high-speed circular saw

machine stands out, particularly excelling at cutting tasks at

various angles. Its core lies in the unique 15° top-down cutting technology. Combined with high-speed operation, intelligent

automation, exceptional precision, and eco-friendly features, it

has become an essential high-efficiency device for modern

production lines.

This machine efficiently processes various common metal profiles

such as round pipes, angle steel, and square tubes. Its design

significantly enhances processing flexibility, eliminating the need

for frequent clamp changes due to variations in material shape or

size, and easily handling diverse cutting demands.

The 15° top-down cutting path is its core technological advantage. This design

scientifically disperses cutting stress, minimizes impact on the

workpiece, and consistently produces smooth, flat cut surfaces.

This characteristic is particularly crucial for applications

demanding stringent requirements for cutting edge finish.

The equipment integrates an advanced transmission system and a

high-strength clamping mechanism. Through precise structural

design, it achieves secure workpiece fixation. Even under the

powerful dynamic loads of high-speed cutting, it effectively

suppresses workpiece displacement, providing a solid guarantee for

the stability of the entire cutting process and the repeatability

of results.

The machine's core is its powerful intelligent control module. It

precisely regulates key process parameters such as cutting speed

and angle, ensuring each cut is accurate, efficient, and strictly

adheres to preset standards. The equipped high-precision CNC system

supports intuitive human-machine interface (HMI) programming.

Operators can easily preset cutting parameters and store multiple

machining programs through the user-friendly interface, enabling

fully automated production processes. This not only significantly

reduces manual intervention but also markedly lowers the risk of

operational errors.

Specifications:

| Model | Unit | JSSCD-160NC/X |

| Mainframe dimensions | mm | 2250*1800*1890 |

| Bar & round pipe | mm | 20-120 |

| Angle bar & square bar | mm | 20-95 |

| Saw blade size | mm | φ380*2.6*φ40 |

| Pin holes and hole diameters | mm | 4*φ11*90 φ40 |

| Spindle motor power | KW | 11(4P) |

| Spindle speed | rpm | 20-140 |

| Feeding servo motor power | KW | 2 |

| Feed servo motor power | KW | 2 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 2.25(4p) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 100 |

| Cut off feed mode |

| AC servo motor & ball screw / 15° cutting-in |

| Main clamping method |

| Hydraulic type / one set each for horizontal and 15° |

| Saw blade debris removal device |

| Passive/active circular wire brush (optional) |

| Gear backlash compensation device |

| Hollow external rotating magnetic powder brake |

| Feeding drive mode |

| AC servo motor & ball screw |

| Feeding clamp method |

| Hydraulic type/Horizontal clamping |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system |

| Timed and quantitative forced oil supply |

| Micro-lubrication system for cutting |

| Quasi-dry intermittent oil supply |

| Material separating device |

| Pneumatic reciprocating |

| Long material receiving device |

| Optional |

| Blade swing anti-vibration device |

| Tungsten carbide parallel block |

To meet larger-scale production needs, the machine can be

optionally equipped with an automatic feeding system. This system

supports continuous batch cutting operations, allowing the

equipment to run uninterrupted for extended periods. This elevates

production efficiency to new heights, powerfully supporting

enterprises' high-volume production goals.

This equipment perfectly balances the dual challenges of

high-volume production and high-precision machining. It is a

powerful tool for enterprises to enhance production efficiency and

processing quality, providing stable and reliable cutting assurance

for metalworking lines. By integrating intelligent control with

high-speed cutting technology, it effectively increases material

utilization rates, reduces waste, accelerates production pace,

shortens delivery cycles, and optimizes labor costs. For

metalworking enterprises committed to enhancing market

competitiveness, this machine is an ideal choice for achieving

sustainable development and building modern workshops, injecting

robust momentum into their growth.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a

30,000 square meter factory and a team of dedicated technicians

specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our

city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a

test cut using our machine. After the test is complete, we will

provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for

your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of

your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.