JSSCD-110NC/X CNC High Speed Circular Saw Machine(Angled-Push)

Description

Within the demanding metal fabrication sector, where maximizing

output and maintaining exactness are critical, this engineered CNC

high-speed circular saw offers a distinct advantage. It is

particularly adept at executing cuts across a wide range of angles.

The defining feature is its specialized 15-degree downward cutting motion. When integrated with rapid operation,

smart automation, superior accuracy, and environmentally conscious

design, it emerges as a vital high-productivity asset for

contemporary manufacturing setups.

This unit capably handles diverse standard metal profiles including

tubes and structural sections. Its engineered design substantially

improves operational adaptability. This minimizes the necessity for

repeated fixture adjustments caused by differences in material form

or dimensions, effortlessly accommodating varied cutting

specifications.

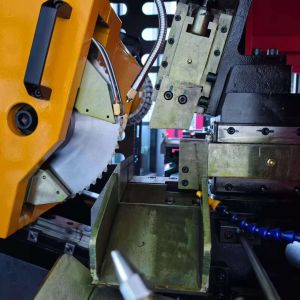

The 15-degree downward cutting path represents its primary technological

innovation. This approach scientifically distributes cutting

forces, significantly lessening impact on the part, and

consistently yields clean, planar cut faces. This attribute is

especially vital for applications with rigorous demands on cut edge

quality.

The machine incorporates a sophisticated drive system and a robust

workholding mechanism. Meticulous structural engineering ensures

reliable part immobilization. Even during the high dynamic loads of

fast cutting, it effectively prevents workpiece movement, offering

a firm foundation for process consistency and result

reproducibility.

At its heart lies a potent intelligent control unit. This module

accurately governs critical operational parameters like feed rate

and cutting angle, guaranteeing every operation is precise, rapid,

and strictly conforms to predefined specifications. The integrated

high-accuracy CNC system features an ergonomic Human-Machine

Interface. Operators can conveniently predefine cutting sequences

and store numerous operation programs via the streamlined

interface, enabling comprehensive automated workflows. This

drastically minimizes manual involvement while substantially

decreasing the potential for operational mistakes.

Addressing larger-scale production volumes, the machine offers an

optional material handling system. This add-on facilitates

uninterrupted batch processing, enabling extended periods of

continuous operation. This pushes productivity to elevated levels,

robustly supporting companies' objectives for high-volume output.

Specifications:

| Model | Unit | JSSCD-110NC/X |

| Mainframe dimensions | mm | 2230*1800*1890 |

| Bar & round pipe | mm | 20-100 |

| Angle bar & square bar | mm | 20-85 |

| Saw blade size | mm | φ360*2.6*φ40 |

| Pin holes and hole diameters | mm | 4*φ11*90 φ40 |

| Spindle motor power | KW | 11(4P) |

| Spindle speed | rpm | 20-140 |

| Feeding servo motor power | KW | 2 |

| Feed servo motor power | KW | 2 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 2.25(4p) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 100 |

| Cut off feed mode |

| AC servo motor & ball screw / 15° cutting-in |

| Main clamping method |

| Hydraulic type / one set each for horizontal and 15° |

| Saw blade debris removal device |

| Passive/active circular wire brush (optional) |

| Gear backlash compensation device |

| Hollow external rotating magnetic powder brake |

| Feeding drive mode |

| AC servo motor & ball screw |

| Feeding clamp method |

| Hydraulic type/Horizontal clamping |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

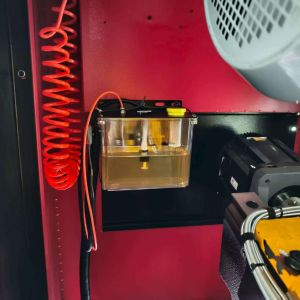

| Self-lubrication oil system |

| Timed and quantitative forced oil supply |

| Micro-lubrication system for cutting |

| Quasi-dry intermittent oil supply |

| Material separating device |

| Pneumatic reciprocating |

| Long material receiving device |

| Optional |

| Blade swing anti-vibration device |

| Tungsten carbide parallel block |

This equipment masterfully reconciles the dual demands of mass

production and exacting machining. It serves as a powerful

instrument for businesses aiming to boost throughput and

workmanship quality, delivering steadfast and reliable cutting

performance for metalworking operations. By merging intelligent

command with high-velocity cutting, it effectively improves

material yield, diminishes scrap, quickens production tempo,

compresses lead times, and optimizes workforce expenditure. For

metal fabricators focused on strengthening market position, this

machine is an optimal selection for pursuing sustainable growth and

establishing modernized production facilities, infusing strong

momentum into their advancement.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a

30,000 square meter factory and a team of dedicated technicians

specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our

city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a

test cut using our machine. After the test is complete, we will

provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for

your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of

your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.