Baoji Lihua Nonferrous Metals Co., Ltd.

Baoji Lihua Non-ferrous Metal Co., Ltd. was established in 2006. The company relies on theadvantages of Baoji industry and its

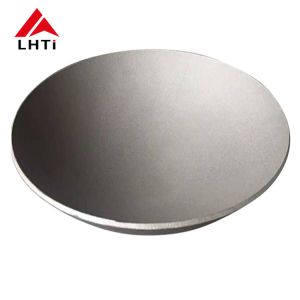

strong technical support. It has been engaged in theproduction and

sales of non-ferrous metals such as titanium, tantalum and nickel

for many years.

The factory covers an area of 800 square meters. The factory has strong technical equipment. There are more than 20 sets of CNC machines, milling and drilling

machines, and the annualproduction value is more than 30 million CNY.

The company's product is high quality and stable for many years,

and it has obtained the Certification ISO 9001:2015, BV audit certification.

The company has been focusing on the improvement and stability of

product quality for many years. Based on the business concept of maximizing customer

service, we warmly welcome you to come for advice and business negotiation!