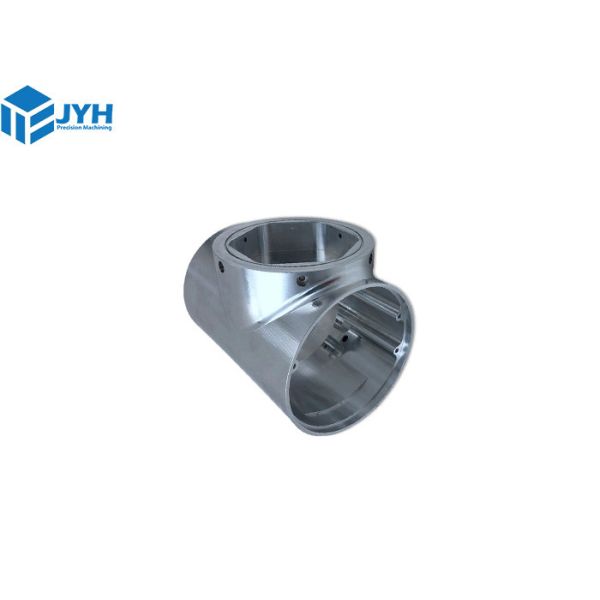

Manufacture OEM CNC custom service stainless steel turning parts

OEM CNC Turning Service For Metal Stainless Steel Parts In

Automotive Fields

OEM CNC Turning is an intricate and detailed method of creating

custom parts and components using a lathe. Computer

Numerical Control (CNC) turning is a highly-skilled, Precision

Engineering process. Based on one of the oldest machine tools in

the world.

Features:

l High precision: CNC lathe machining can achieve micrometer level

machining accuracy, meeting the CNC Turned Parts machining

needs of high-precision parts.

l High efficiency: Through pre programmed instructions, CNC lathes

can achieve automated machining, greatly improving machining

efficiency.

l Strong adaptability: CNC lathes can process parts of various shapes

and sizes, with strong adaptability.

l Material diversity: CNC lathes can process various materials,

including steel, stainless steel, special materials, etc.

l Application: CNC Turned Parts are widely used in fields such as mechanical manufacturing,

automotive manufacturing, aerospace, medical devices, etc.

Especially in situations of high precision, high efficiency, and

large-scale production, CNC lathe machining has significant

advantages.

Parts Certifications

ISO 9001:215 | AS9100D | ITAR Registered

Surface Treatment Available for Different Materials

Stainless Steel | Drawing and polishing, sandblasting, laser engraving, etc. |

Steel | Galvanized, black oxide, chrome plating, powder spraying, etc. |

Aluminum parts | Clear anodizing, color anodizing, sandblasting anodizing, brushing,

polishing. |

Titanium | Sandblasting,Brushing,Polishing,Plating, Passivating. |

CNC Turning Tolerances

As an ISO 9001 certified company, we machine CNC turning lathe

parts to meet tight tolerance requirements.

Based on your design, our CNC lattes can reach tolerances of up to

±0.005”.

Our standard tolerances for CNC milled metals is ISO 2768-m and ISO

2768-c for plastics.

Type

| Tolerance |

Linear dimension

| +/- 0.025 mm +/- 0.001 inch

|

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch

|

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch

|

| Part size limit | 900 * 550 * 450 mm 37.0 * 21.5 * 18.5 inch

|

Precision Machined Part Size Standards

CNC turning is often used for:

- ►functional prototypes and end-use parts

- ►parts with cylindrical features

- ►parts with axial and radial holes, flats, grooves, and slots

FAQ:

1. What parts can CNC turning make?

JYH: The CNC turning process is mostly ideal for cylindrical-shaped raw

materials.

However, several manufacturers also use it for hexagonal and

square-shaped workpieces.

It is a popular method for making machine parts for microfluidic

tools, signage components,

surgical instruments, automotive frames, and aerospace parts.

2. What is your maximum diameter capacity for turned parts?

JYH: We can turn parts with diameters ranging from 0.5mm to 65mm for

stock bars.

Our turning capabilities can reach up to 3000 mm for billets.

3. Can you produce plastic turned parts?

JYH: Yes, our CNC turning services include plastic parts manufacturing.

We can produce small or

large batch prototypes and production parts from various

engineering-grade plastics.

Choose from our extensive range of plastic materials and upload

your design file to get custom plastic components.

4. What’s the difference between CNC milling and CNC lathe?

JYH: The major difference between CNC milling and CNC lathe is in their

machining process.

CNC milling involves rotating the cutting tools against a

stationary bar stock or workpiece.

In contrast, a CNC lather works by rotating the bar stock or

workpiece against a stationary tool.

CNC milling is more suitable for machining irregular and flat

surfaces, while CNC lathes work best for

cylindrical or conical parts.

Surface Finish Options for Turned Parts

( Quick-turn Finishing )

Our part finishing services are exceptional as our teams are

experts in plastic, composite, and metal surface finishing.

Furthermore, we have state-of-the-art machines and infrastructure

to bring your idea to life.

Our quality endure system

Payment method

Shipping way

After sales service

Our workshop:

JYH technology, Your Professional CNC turning Manufacturing

Services Partner!