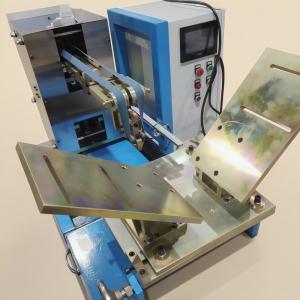

Automatic Dual-Table Metal Seam Welding & Pressing Machine

Automatic Dual-Table Metal Seam Welding & Pressing Machine

I. About Us

STARPOWER has been deeply engaged in the R&D and manufacturing

of metal processing equipment for many years. With a profound

understanding of industrial processing scenarios and accumulated

technical expertise, we have become a well-known provider of

precision equipment solutions in the industry. Adhering to the

philosophy of "Precision Empowers Production, Innovation Drives

Efficiency", we strictly control every step from core technology

R&D to manufacturing. Our products have not only obtained

ISO9001 quality management system certification (add other

certifications if applicable) but also been exported to more than

30 countries and regions worldwide. We have served thousands of

manufacturing enterprises, including leading clients in the fields

of auto parts, pressure vessels, and high-end hardware,

accumulating rich industry cases and a solid reputation.

II. Product Introduction

The SP-WP2024 Automatic Dual-Table Metal Seam Welding & Pressing

Machine is a precision-engineered industrial automation solution

designed for high-efficiency metal processing operations. This

robust equipment integrates advanced welding and pressing

functionalities into a single integrated system, ideal for

manufacturing facilities requiring consistent quality and

productivity.

- Dual-Table Configuration: Features two symmetrical tilting metal worktables with precision

clamping mechanisms, allowing simultaneous loading/unloading and

processing for continuous workflow

- Mechanical Processing Unit: Equipped with a horizontal sliding mechanical arm assembly with

adjustable pressure settings, capable of handling complex seam

welding and edge pressing tasks

- Control System: Intuitive HMI touchscreen display with physical emergency stop

and operation buttons, ensuring operator safety and process control

- Sturdy Frame: Heavy-duty blue-painted steel frame with gray access panels,

providing stable operation and vibration resistance during

high-force processing

- Working Table Dimensions: 450×350mm per table (estimated)

- Tilting Angle: 0-90° adjustable worktable positioning

- Processing Capacity: Suitable for metal sheets up to 3mm thickness

- Power Supply: 380V 3-phase industrial power

- Control Method: PLC programmable logic controller with 100+ program storage

capacity

- Machine Dimensions: 1200×800×1800mm (L×W×H, estimated)

- Semi-Automatic Workflow: Combines automated processing with manual loading for optimal

flexibility

- Quick Changeover: Tool-free adjustment knobs for rapid parameter setting between

different workpieces

- Integrated Lighting: Articulating LED work light for enhanced visibility during

precision operations

- Safety Interlocks: Dual-hand operation and emergency stop system meeting CE safety

standards

Ideal for metal fabrication industries including electrical

enclosure manufacturing, automotive component production, furniture

hardware processing, and sheet metal engineering. Particularly

effective for processing right-angle seams, edge pressing, and

decorative beading on carbon steel, stainless steel, and aluminum

alloys.

- High-grade aluminum alloy mechanical components with hardened steel

tooling

- Anti-corrosive powder-coated finish resistant to industrial

workshop environments

- Sealed bearing assemblies for maintenance-free operation up to

10,000 hours

- Centralized lubrication points for extended mechanical lifespan

V. Application Scenarios

• Hardware Manufacturing: Rounding treatment for weld corners of products such as hinges,

handles, and brackets, improving surface smoothness, avoiding

scratches during use, and enhancing product safety.

• Pressure Vessel Production: Precision rounding of welded parts in storage tanks, pipelines,

etc., eliminating stress concentration and improving

pressure-bearing capacity and corrosion resistance.

• Mechanical Structure Manufacturing: Processing welds of welded components like frames and chassis,

optimizing overall mechanical performance and extending equipment

service life.

| Parameter | Specification |

|---|

| Product Name | Automatic Dual-Table Metal Seam Welding & Pressing Machine |

| Model | SP-WP2024 |

| Working Table Dimensions | 450×350mm per table (estimated) |

| Tilting Angle | 0-90° adjustable |

| Processing Capacity | Metal sheets up to 3mm thickness |

| Power Supply | 380V 3-phase industrial power |

| Control Method | PLC programmable logic controller |

| Program Storage | 100+ program capacity |

| Machine Dimensions | 1200×800×1800mm (L×W×H, estimated) |

| Frame Material | Heavy-duty blue-painted steel |

| Worktable Material | Metal with precision clamping mechanisms |

| Operation Mode | Semi-automatic (automated processing + manual loading) |

| Safety Features | Dual-hand operation, emergency stop system (CE compliant) |

| Integrated Lighting | Articulating LED work light |

| Tool Adjustment | Tool-free adjustment knobs |

| Mechanical Components | High-grade aluminum alloy with hardened steel tooling |

| Finish | Anti-corrosive powder-coated |

| Maintenance | Sealed bearing assemblies, centralized lubrication points |

| Operational Lifespan | Up to 10,000 maintenance-free hours |

VI. Customer Benefits

• Quality Upgrade: Precise grinding improves product details, helping customers

create high-value-added products and enhance market

competitiveness.

• Cost Reduction & Efficiency Improvement: Automated operation reduces labor costs, and efficient processing

increases production capacity, enabling quick response to order

demands.

• After-Sales Guarantee: As the source manufacturer, STARPOWER provides 7x24 technical

support, free installation and commissioning, and a 1-year warranty

(adjust according to actual policies), ensuring customers have no

worries.

Choosing STARPOWER's Vertical Seam Internal Round Corner Grinding

Machine means more than just purchasing a device; it means

partnering with an industry-experienced technical expert. We will

support your production processes to be more efficient and your

product quality to be more excellent with professional products and

services.