Zhuzhou Sanxin Cemented Carbide Manufacturing Co.,Ltd is located in

Zhuzhou, Hunan Province, which is known as the “Hometown of

Cemented Carbide”. It is a national high-tech enterprise that has

passed ISO9001:2015 international quality certification system,

specializing in manufacturing, research and development of cemented

carbide materials and tungsten steel products’ raw material, blank

production, tungsten steel precision processing and sales one-stop

service.

Zhuzhou Sanxin Cemented Carbide Manufacturing Co.,Ltd inherits and

precipitates Zhuzhou cemented carbide tungsten steel processing

technology. We have a professional technical team, which lays a

solid foundation for manufacturing high quality cemented carbide

products. The advantages of cemented carbide products in related

fields are obvious. We can provide you with a complete set of

cemented carbide products and tungsten steel product solutions.

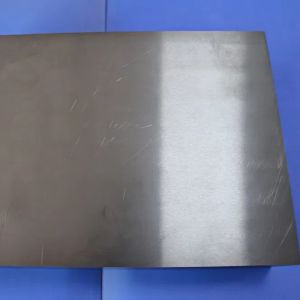

Zhuzhou Sanxin Cemented Carbide Manufacturing Co., Ltd produces and

processes tungsten steel products, selects suitable cemented

carbide materials, owns professional customized precision

equipment, unique processing technology, implements strict quality

control measures of 100% inspection and provides considerate

pre-sales and after-sales services. We can produce and process

non-standard custom carbide inserts, carbide cutters, carbide

molds, carbide fixtures, carbide sheets, carbide rods, hard for

customers who need it. Alloy pipe, carbide punching punch, carbide

valve seat, carbide insert, cemented carbide nozzle, carbide wear

parts, carbide mold parts, and other cemented carbide tungsten

steel precision processed products for customers who have needs.

We focus on every process of cemented carbide production and

processing, and we are able to meet the needs of our customers'

usage requirements on precision tungsten steel processing to the

maximum.

Why choose us:

We always implement these business policies of "quality first,

customer first"; "both wholesale and retail are welcome, excellent

price for large quantity"; "timely delivery, mutual benefit and

simultaneous growth with customer " to expand ourselves in the

market.

Why rely on us:

We will continue to uphold the concept of “forge ahead”, “focus on

innovation”, “based on quality, focus on brand” and “provide

products with super-expected value for customers”and make ourselves

on the road to development.

Why cooperate with us:

We always adhere to the principle of “quality is life”, “service

creates value”, “cooperation promote development”, “support

partners, develop ourselves”to cooperate with you for developing

together.