Qingdao Wanguo Sanchuan Fiber Technology Co., Ltd.

Advanced Composite Solutions Engineered for Global Excellence

Founded in 2008 and headquartered in Qingdao, China, we specialize

in high-performance fiber composites for demanding industrial applications. Leveraging DNV-GL certified

manufacturing and ISO 9001:2015 quality systems, we deliver

mission-critical material solutions to clients across 35+

countries.

Core Capabilities

- Innovation-Driven R &D: 150+ engineers advancing composite technology through patented

processes

- Global Compliance: REACH SVHC-free materials with full RoHS 3 certification

- Precision Manufacturing: AI-powered production lines with real-time quality monitoring

Premium Product Portfolio

Our DNV-GL/CCS certified product range includes:

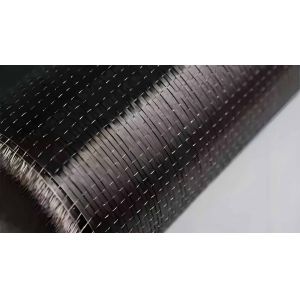

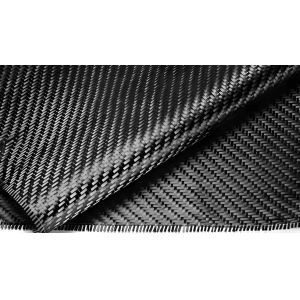

- Carbon Fiber Systems: Unidirectional tapes & woven fabrics for aerospace and wind

energy

- Glass Fiber Solutions: EC9 roving, balanced fabrics, and chopped strand mats for

construction

- Specialty Composites: Marine-grade basalt fiber geogrids and UHMWPE mooring ropes

- Engineered FRP: Corrosion-resistant panels and UV-stable skylights for industrial

roofing

- Polymer Matrix: Vinyl ester resins for chemical tanks and RTM consumables

All products contain no PFAS or substances restricted under EU

Regulation 2023/707

Global Applications

We empower critical industries with validated material performance:

- Renewable Energy: Spar caps for Siemens Gamesa 14MW turbines (20-year fatigue

resistance)

- Marine Engineering: Hull reinforcement systems for Maersk vessels (15+ years

saltwater durability)

- Infrastructure: Seismic retrofitting composites for Hong Kong-Zhuhai Bridge

- Industrial Protection: Chemical barrier linings certified to ISO 28721-3

Certifications & Compliance

- Quality Assurance: ISO 9001, IATF 16949

- Environmental Standards: ISO 14001, Recycled Content Declaration

- Industry Approvals: DNVGL-RP-0419 (marine), UL 1446 Class H (electrical)

- Safety Protocols: OSHA 1910.120 compliance for hazardous environments

Our Commitment

Guided by our principle "Precision Engineered, Globally Trusted", we enable client success through:

Material Innovation: Proprietary basalt fiber technology /Proprietary carbon fiber

technology

Supply Chain Transparency: Blockchain-verified raw material sourcing

Sustainable Growth: Science-based carbon reduction targets (SBTi validated)