PE Irrigation Pipe Extruder Making Machines Plastic Machines

APPLICATION:

PE feed pipe is special polyethylene as raw material with a plastic

extruder extrusion molding, applied to urban water supply pipe

network, the irrigation water diversion project and agricultural

irrigation project, especially suitable for acid and alkali

corrosion environment, the plastic tubing.Because of using PE pipe

hot melt, hot melt connection to realize the integration of the

interface and pipe, and can effectively resist the pressure of hoop

stress and axial stress, the impact of heavy metals and PE pipes

don't add salt stabilizers, material of non-toxic, not scaling, do

not breed bacteria, to avoid the secondary pollution of drinking

water.PE feed pipe is special polyethylene as raw material with a

plastic extruder extrusion molding, applied to urban water supply

pipe network, the irrigation water diversion project and

agricultural irrigation project, especially suitable for acid and

alkali corrosion environment, the plastic tubing.Because of using

PE pipe hot melt, hot melt connection to realize the integration of

the interface and pipe, and can effectively resist the pressure of

hoop stress and axial stress, the impact of heavy metals and PE

pipes don't add salt stabilizers, material of non-toxic, not

scaling, do not breed bacteria, to avoid the secondary pollution of

drinking water.

PE PIPE PRODUCTION SPECIFICATIONS:

| Model | Pipe diameter | Extruder | Extruder power | Capacity |

| LB-63 | 20-63 | SJ65/33 | 55AC | 150 |

| LB-110 | 20-110 | SJ65/33 | 55AC | 150 |

| LB-160 | 75-160 | SJ75/33 | 90AC | 280 |

| LB-250 | 90-250 | SJ75/33 | 110DC | 350 |

| LB-315 | 110-315 | SJ90/33 | 160DC | 450 |

| LB-450 | 160-450 | SJ90/33 | 160DC | 450 |

| LB-630 | 315-630 | SJ120/33 | 280DC | 850 |

| LB-800 | 500-800 | SJ150/33 | 315DC | 1100 |

| LB-1200 | 710-1200 | SJ150/34 | 400DC | 1350 |

Production Flow:

Raw material+Color master batch---Vacuum Loader---Hopper

Dryer---Single Screw Extruder---Color line Co extruder---Vacuum

calibration Tank---Water Cooling Tank---Words Printer---Haul

off---Cutting machine---Stacker/Winding machine.

Single Screw Extruder Machine

PE (Polyethylene) & Carbon Fiber Mixing: High-density polyethylene

(HDPE) and carbon fiber materials are prepared and mixed to enhance

strength and durability.

Extrusion Compound Preparation: The mixture is processed into a

uniform compound for extrusion.

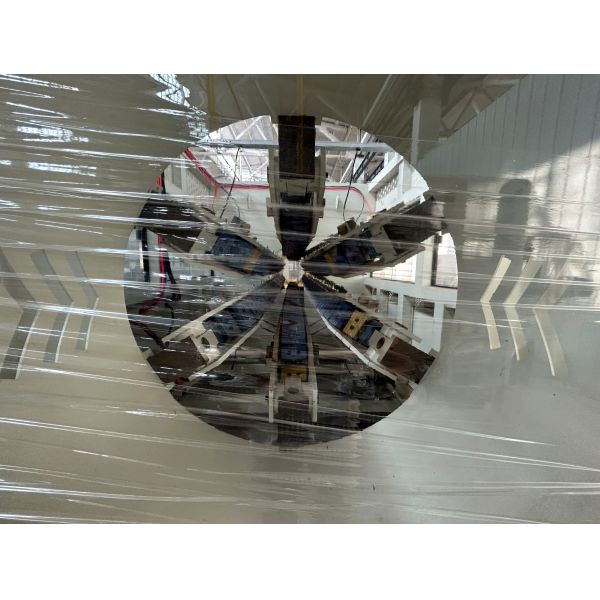

pipe extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the

thermal decomposition of amorphous plastics and get high quality

pipes. There is heating control system inside of the mould, high

efficient, easy to extrude. Bronze calibrators can make the pipes

fast calibrated and cooled.

Vacuum cooling tank and spraying cooling tanks:

Rapid vacuum calibrating system allows the hot extruded pipes to be

cooled in a very short time and obtain the final pipe diameter.

Automatic temperature control system, pressure regulator, and

vacuum control valve greatly enhance the pipe sizing and cooling

performance as well as the production speed.

Haul off machine:

Adopts caterpillar type, which includes two-claw types, three-claw

types, four-claw types, six-claw types, eight -claw types, ten-claw

types, twelve-claw types etc, suitable for different sizes of

pipes. Haul off caterpillar blocks are made of abrasion resistant

rubber material, which can make a high and stable hauling speed.

Cutting machine:

Precision machine cutter is able to make flat, straight cuts into

pipes at high speed. A powerful suction device gathers up waste

scraps after cutting, thereby making it easier for users to clean

the cutter.

Pipe stacker or pipe coiler

Automatic pipe stacker for packing the pipes, pipe coiler for small

PE pipes like 16-40, 16-75mm, 50-110mm.

Feature and Function of the machines:

The screw of the extruder is equipped with barrier unit and mixing

structure,and the barrel owns new style grooves.All of these offer

good plastification and mixing effect.Special design of basket die

head for PE large diameter pipe with thick wall offer lower melting

temperature,good mixing,lower pressure of cavity,and stable

production.

Special design for sizing and cooling system by using film and

water ring to PE material,which can fit for the requirement of

PE.And the design can ensure the stability of diameter and

roundness when producing the pipe with thick wall.

Special design vacuum sizing tank can ensure the stability of size

and roundness.Speed controllers are used in extruder,haul-off to

offer stability and precision.

The whole line adopts PLC control system and large liquid crystal

screen,which makes the operation very convenient.The line can be

equipped with another extruder used for extruding the mark line.

PRE- AND AFTER-SALE SERVICES

• A great wealth of experience,

• A consistent focus on the highest quality

• A complete twin pipe vacuum sizing system;

• Controlled independently unitary structure twin pipe hauling

mechanism and synchronous cutting device;

• Optional length set and accurate adaption stacker.

• A highly motivated team

• Sophisticated process technology

• Customized solutions

Our factory

Our exhibition

Our goods shipping