Product description

Stainless steel is a strong and highly durable material that is

perfect to be used in interior and exterior constructions and

design features. Using colored stainless steel sheets means that

design professionals can integrate the element of color into their

designs, instead of opting for the regular stainless steel look.

color stainless steel produces different types of colored stainless

steel sheets, which are manufactured to the highest standards and

from top quality materials.

Specification

| Decorative Stainless Steel Plate |

| 2000 / 2438 / 3000 / 3048 / 3500 /4000/ 5800mm/6000mm/12000mm/or as

required. |

| 1000 / 1219 / 1500 mm |

| Cold rolled:0.3~3.0mm; Hot rolled:3.0~120mm |

| 200 series,300 series,400 series |

| JIS, AISI, ASTM, DIN, TUV, BV, SUS,etc |

| Golden/Zr-brass/Black / Rose gold/ Champagne/ Bronze/Brown/Sapphire

Blue/ Purple/ Gray/ Silver/Biolet/ PVD black /Wine red/Rose

red/Antique copper/Antique bronze/Antique brass/Titanium gold/black

titanium/green/etc |

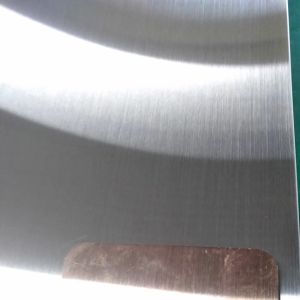

| 2B/BA/8K(mirror)/NO.4(Sand

blasting)/No.1/Hairline(brushed)/Etching/Embossed/Vibration/ PVD

coating,etc. |

| Interior/exterior/architectural/bathroom decoration, elevator

decoration, hotel decoration, kitchen equipment, ceiling, cabinet |

| 7 to 20 working days after the receipt of 30% deposit |

| Wooden pallet or according to customer's request |

The Process of Mirror

A highly reflective finish, it achieves the look for which

stainless steel is best known. It works great to hide welded metal

and makes cleaning easier. Polishing stainless steel to attain a

mirror finish requires a wheel or at least a 320-grit belt

PVD Coating

The PVD (Physical Vapor Deposition) coloring process for stainless

steel surfaces is an advanced treatment.

Principle: In a vacuum, metal target materials (e.g., titanium, zirconium)

are vaporized via magnetron sputtering or evaporation, then deposit

on the stainless steel to form a colored coating through chemical

and physical reactions.

Process Steps: Pre-treat by cleaning, degreasing, and slight etching; load into

the vacuum chamber, create a high vacuum; energize the target

during deposition, precisely controlling temperature, pressure,

etc.; cool down and post-treat with passivation or sealing.

Advantages: Strong bond for good wear and scratch resistance; offers various

vibrant colors; environmentally friendly without harmful chemicals;

enhances corrosion resistance.

Applications: Widely used in jewelry, watchmaking, architecture, automotive,

and consumer electronics for decorative and aesthetic purposes.

Product details

welcome to inquiry lea

contact me :lea@mxlbxg.com

WhatsApp&Zalo&Wechat:+8618125616886

Application

Construction Decoration ,

Interior & Outdoor Decoration ,

Five-star Hotel Decoration.

Luxry Shop Decoration

Office Decoration.

We Can Provide Our Stainless Steel Manual (Sample Book) for

Decoration Designer in Free.

We Can Provide Our Stainless Steel Manual (Sample Book) for

Decoration Designer in Free. Packing And Loading

FAQs

Get answers to all your questions fast here from our Frequently

Asked Questions.

Q:How can I get some samples?

A:Catalogue and most sample pieces are preparing for you already in

stock.

Customized samples will take about 5-7days. Please contact us for

further support.

Q:What kinds of payment methods do you accept?

A:We accept the payment by T/T or L/C, besides, you can transfer to

our bank account, Western Union or PayPal.

Q:What is the average lead time?

A:For samples, the lead time is about 5-10 days.

For mass production, the lead time is 10-25 days. In all cases, we

will try best to accommodate your needs.

Q:Can you supply the relevant documentation?

A:Yes, we can provide most documentation such as Inspection

Certificate/Mill Test Certificate, Insurance, Certificate of

Origin, SASO, Form E, and other export documents what required.