YIbeino New Materials focuses on the research and development of

new wear-resistant ceramic materials and is committed to providing

material conveying, pneumatic conveying system engineering design

and equipment wear problems under various complex working

conditions for cement, thermal power, steel, coal, port, chemical,

new energy, mineral processing, engineering machinery, concrete

pipe pile, and other industries. We have 20 years of industry

experience in the field of wear-resistant materials, We provide

one-stop service from production to installation, according to

customer demand for product design, research and development,

production, processing, and other services.

The company has a professional anti-wear construction team. Relying

on our strong technical strength and years of accumulated practical

experience, we can provide timely solutions to various wear

problems and select appropriate wear-resistant materials and

construction plans based on actual working conditions. Rational

product design, on-site construction, and comprehensive after-sales

service can help you effectively improve the operating efficiency

and service life of your equipment and solve equipment wear

problems under various complex working conditions.

We have more than 20 years of industry experience in the field of

wear-resistant materials and a group of experienced technical and

management personnel. We can provide product design, research and

development, production, processing, and other services according

to customer needs. The company has a full set of advanced equipment

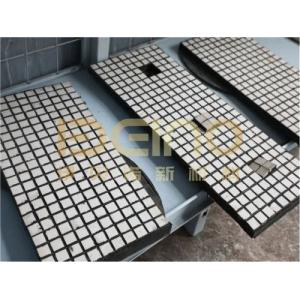

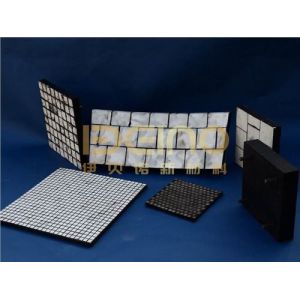

for the production of wear-resistant products. Our company's main

products are wear-resistant ceramic sheets, wear-resistant ceramic

liners, ceramic composite pipes, wear-resistant ceramic elbows

(lithium battery pneumatic conveying elbows), wear-resistant

ceramic roller lagging, the overall equipment is lined with

ceramics, ceramic pump truck pipes, alumina structural ceramics,

ZTA ceramics and other series of products. The products have high

strength, high hardness, good wear resistance, and corrosion

resistance.

Hunan YIbeino New Materials Co., Ltd. has passed the ISO9001:2015 quality system

certification. The company has a strict quality control system.

Product design, manufacturing, and installation services are fully

integrated into the ISO quality management system. From raw

material purchase and ingredients, All aspects from production

process management to factory inspection and control ensure stable

product performance and excellent quality.

The company has users all over the world, mainly exporting to the

United States, Germany, Sweden, India, Turkey, the Netherlands,

Italy, Spain, Japan, South Korea, Russia, Vietnam and other

countries. The company adheres to the business philosophy of

"integrity, hard work, innovation" and adheres to the "customer We

provide our customers with high-quality services based on the

principle of "quality first", welcome to patronize us!

Company Advantage

The company is a manufacturing enterprise, we have many years of

on-site industry experience and can provide customers with the best

equipment anti-wear design, product samples, quality service, and

competitive prices.

Company Honor

The product patents are as follows: "A kind of elbow of pump

pipe discharge anti-clogging pipe", "A lining board installation

structure", "A lining board processing console", "A conveying

device for ceramic-lined pipes" etc.

Sales Network

Our products are exported all over the world. Our company has

always insisted on the business principle of "quality, innovation,

and customers first".

Our Product

Wear-resistant Ceramic Wear Liner

ZTA Ceramic wear liner

Wear-resistant ceramic composite liner

The Impact resistant ceramic wear liner

Ceramic-composite liner

Ceramic rubber liner

Ceramic-composite wear-resistant elbow

Wear-resistant ceramic composite pipe

Concrete pump parts

Wear-resistant ceramic sheet

Ceramic and rubber pulley lagging

Cyclone lined with wear-resistant ceramic

Ceramic components