High Speed Rack Z Beam Roll Forming Machine with 15-20 m/min Speed and 5.5 Kw Motor Power for 1.5-2.5 mm Thickness

|

...tems and industrial storage structures. It processes galvanized or cold-rolled steel coils with a thickness range of 1.5–2.5 mm. The production line includes a hydraulic decoiler, precision leveling, punching, roll forming, and automatic cutting system....

Cangzhou Metalign Machinery Co., Ltd.

|

ISO Roll Thread Machine Automatic Construction Works Rebar Screw

|

... steel bar in construction engineering. It is the key equipment for realizing straight threaded connection of reinforced steel bar. The steel bar rolling thread connection technology is suitable for industrial and civil buildings. Its process is simple and...

QIFU Machinery Co., Ltd

|

STT50F Automatic Electric 1300W Metal Rolling Pipe Threading Machine

|

...Rolling Pipe Threading Machine Introduction This machine is applicable to cutting, threading and inner hole chamfering (the chamferer is optional) of pipes for water, electricity and gas, and has the copying device able to automatically cut the standard taper pipe thread, with a reliable clamping device and an advanced cooling & lubrication system. Therefore, adopting this machine......

Hangzhou Suntech Machinery Co., Ltd.

|

Thread Rolling Machine For Making Anchor Bolt , Bar CNC Drilling And Threading Machine

|

Thread Rolling Machine For Making Anchor Bolt Bar CNC Drilling And Threading Machine Threading Rolling Machine 1.Two spindle of the machine rotates synchronously in the same direction .Right spindle feed motion in the horizontal direction under the rolling drive.Two rolling wheels make the work as required and other thread shape by rolling. 2.This machine......

Friendship Machinery Co., Ltd

|

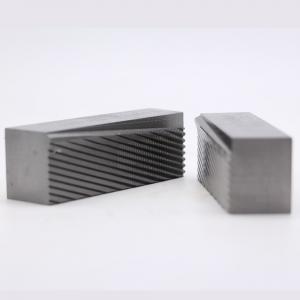

Customized Size Flat Roll Thread Dies

|

...Thread Rolling Die Product Description Please specify the details of thread rolling dies as follows when you inquire or order (1) the material of thread rolling die you need; (2) the type of thread rolling die; machine screw, self tapping screw, wood screw, drywall screw, chipboard screw , duck screw and so on; (3) the fact thread length of screw that you use our thread rolling......

Chongqing Henghui Precision Mold Co., Limited

|

Robust Thread Rolling Equipment Rolling Thread Height 0.5-1.2mm 7.5KW Power Consumption

|

... height between 0.5-1.2mm, rolling diameter between 2.0-3.5mm, rolling thread depth between 0.8-1.2mm and rolling length between 30-100mm. It is powered by 380V/50Hz and is capable of providing excellent performance for a variety of applications. This...

sss hardware industry

|

24'' Big size high quality industrial electric Pipe roll grooving machine supplier

|

...roll grooving machine I. Introduction Roll grooving machine is designed to make roll groove on steel pipe ends. It's powered by gear reducing motor which features integral hydraulic pump and groove depth limitation device, so to provide accurate and quick grooves. The principle of grooving machine......

Hangzhou Suntech Machinery Co, Ltd

|

⌀160-810 Roll Diameter Rubber Mixing Machine with 1 1.35 Rotor Rotating Speed and 1000mm Working Length of Rollers

|

Product Description: The Rubber Mixing Machine is an essential piece of equipment designed specifically for the rubber industry, offering unparalleled efficiency and precision in rubber polymer processing. This advanced Mixing Machine for Rubber is ......

Keribo Heat Exchange Equipment (Qingdao) CO., Ltd

|

THREAD MACHINE(6MM-80MM) 400KN

|

...machine is mainly used for building all kinds of rolling wire through the wall, the top drag ,ladder-threaded and threaded and thread modulus workpiece, with a simple operation,high efficiency advantages. Goods Thread rolling machine Model Z28-250 Pressure of roller max 350KN/400KN Dip angle of main shaft ±15° Working Dia 80mm Rotary speed of main shaft 20,25,41,51,64 (r/min) Thread Distance max 8mm Rolling......

XINGTAI FRIDA IMPORT & EXPORT TRADE CO.,LTD.

|

Woolen Cotton Knitted cloth Fabric Roll Packing Machine

|

...re-rolling fabric. 2.Electronic eye automatically sense,realize releasing fabric without tension. 3.Smoothing fabric function ( Special for elastic fa brie, thread roller can spreading fabric edges to two side, avoid the edges are folding on themselves and...

Changzhou Schneter Textile Machinery CO.,LTD

|