Chengdu Minjiang Precision Cutting Tool Co. Ltd, based in Chengdu, Southwest China, is a leading provider of

high-end wear-resistant parts and precision cutting tools.

Minjiang has been a leader in the industry for the last 30 years

and is committed to providing high-quality products to

clients. Our extensive portfolio of products is designed to provide

maximum efficiency and performance while minimizing wear and tear.

Our commitment to product development and quality improvement has

enabled us to stay at the forefront of the industry for decades.

Through continuous development, we have now formed a complete

blank production line, a finished product production line, and a

complete inspection system, and has passed ISO9001:2015 quality management system certification. Now we are

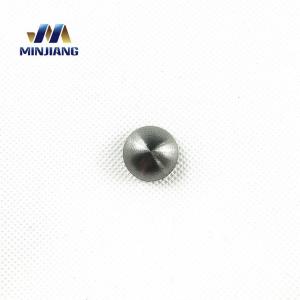

dedicated to the development and production of tungsten-carbide wear parts and bearings, oil pipe thread tools,

CNC tools, lithium battery slitter blades, and other customized

products.

We have cultivated a team of experienced engineers that work

with cutting-edge technology to ensure that the clients benefit

from the highest quality products and services. The company’s

commitment to excellence is evident in the rigorous quality control

measures and the dedication to providing customized solutions to

fit the needs of the clients. With our focus on quality and

reliability, we strive to be a trusted partner for

our clients.

We believe that quality is key to our success and thus we strive

for excellence in everything we do. We are committed to providing

our clients with products that are reliable, safe, and

efficient. Moreover, we are also dedicated to providing our

customers with the best customer service possible.

We look forward to working with you and helping you find the right

products for your needs.

FACTORY

EXHIBITIONS

QMS CERTIFICATE

AWARDS